Method for cleaning inspection of movable machine room cleaning inspection apparatus

A machine room and moving wheel technology, applied in the direction of non-electric variable control, two-dimensional position/channel control, instruments, etc., can solve the problem that the cleaning device does not have the environment detection function, cannot capture real-time environmental pictures, and is not suitable for machine room cleaning, etc. problems, to achieve the effect of facilitating remote understanding, avoiding fires, and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

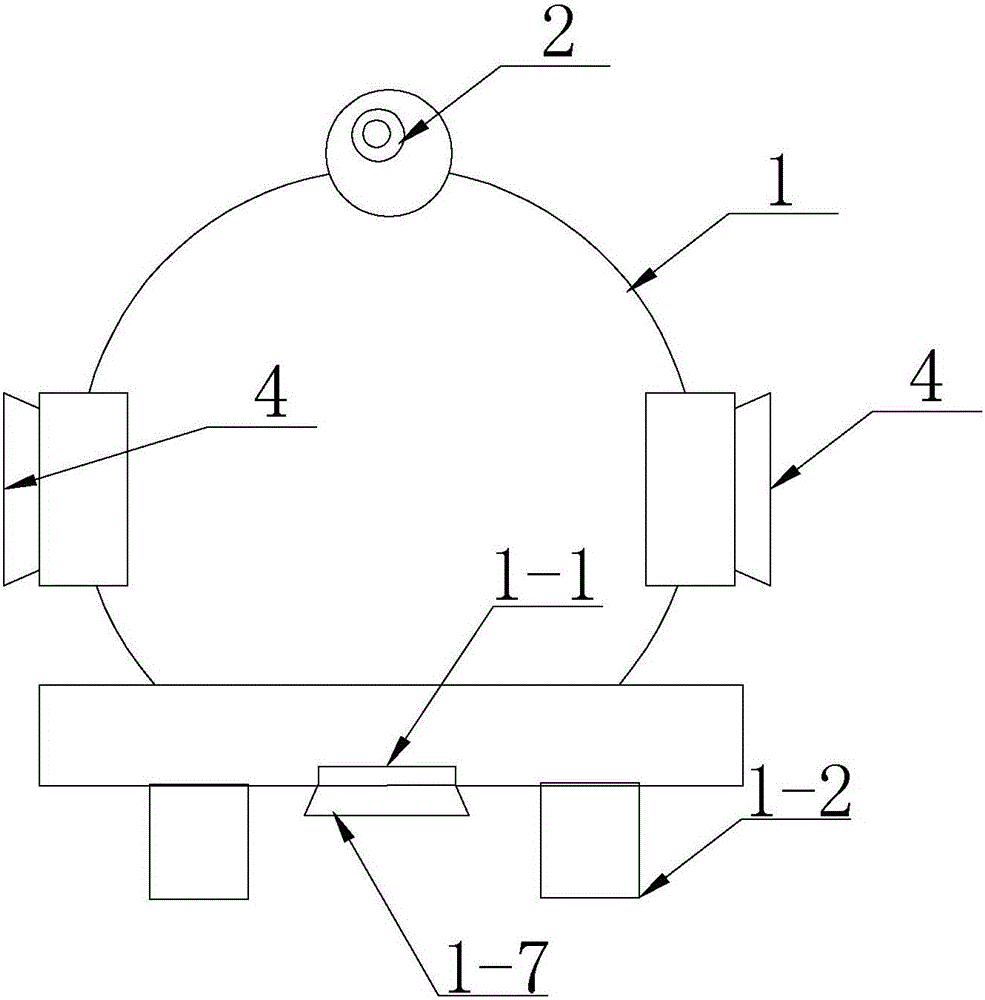

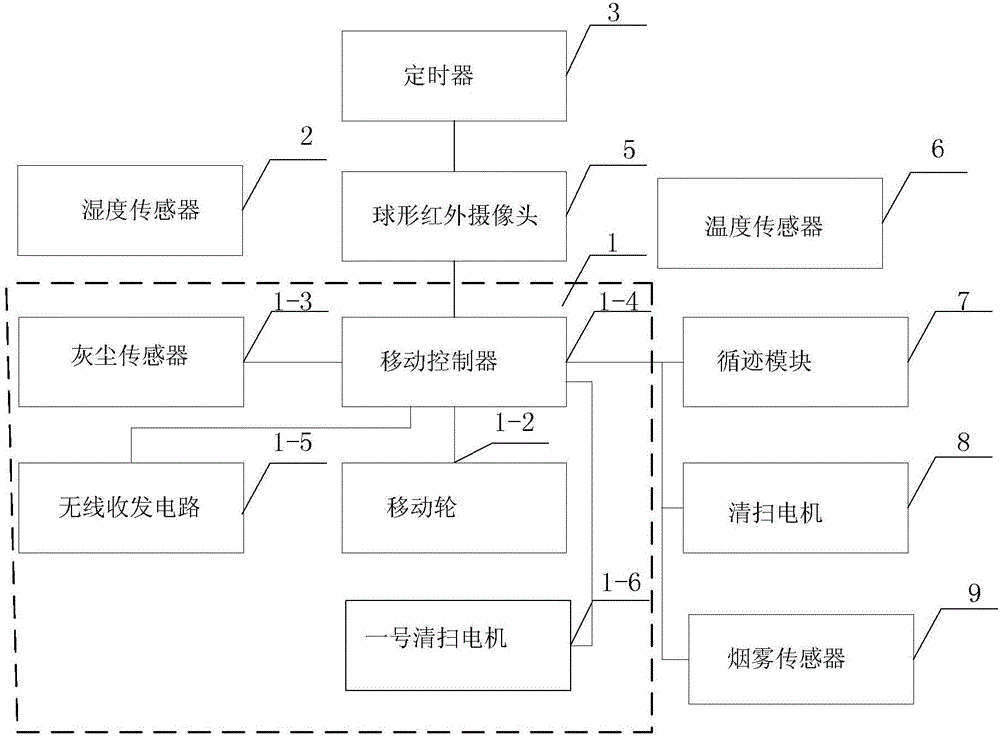

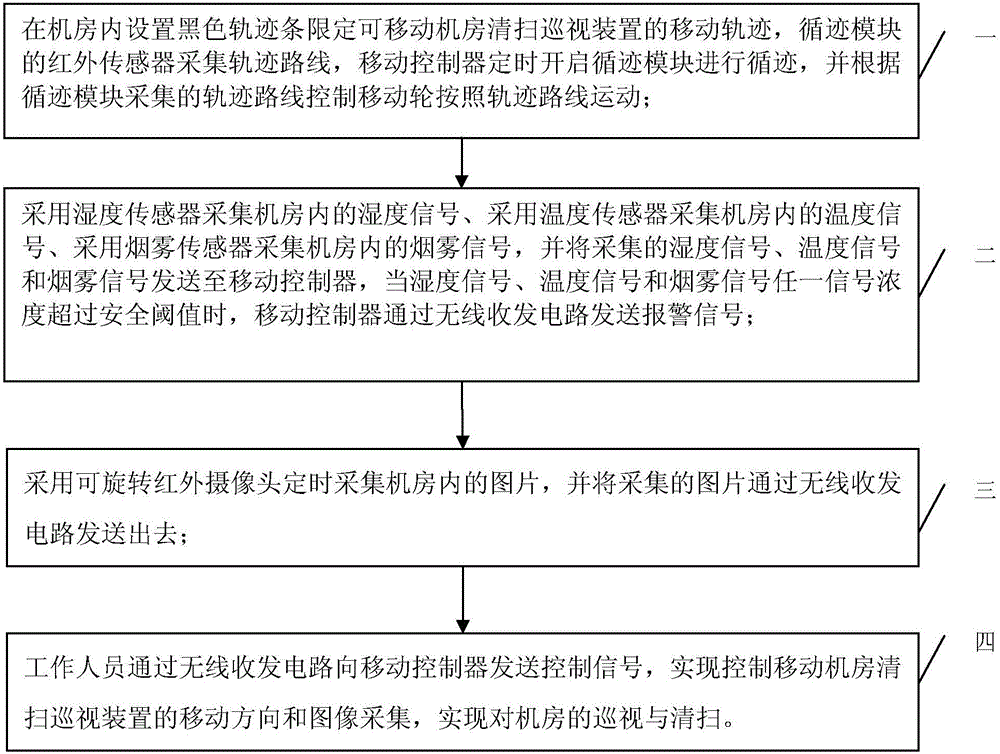

[0023] Specific implementation mode 1. Combination figure 1 , figure 2 with image 3 Describe this embodiment, the method of cleaning and patrolling implemented by the cleaning and patrolling device of the mobile computer room described in this embodiment, the method is realized based on the cleaning and patrolling device of the mobile computer room, the cleaning and patrolling device of the mobile computer room includes a cleaning robot body 1, and the cleaning robot The main body 1 includes a cleaning robot shell, a dust suction device, a moving wheel 1-2, a dust sensor 1-3, a moving controller 1-4, a wireless transceiver circuit 1-5, a No. 1 cleaning motor 1-6 and a No. 1 cleaning brush 1-7;

[0024] Mobile wheel 1-2, dust sensor 1-3, mobile controller 1-4, wireless transceiver circuit 1-5 and dust suction device are all arranged in the cleaning robot housing, and the dust suction port 1-1 of dust suction device is embedded in Clean the center of the lower surface of th...

specific Embodiment approach 2

[0039]Specific Embodiment 2. This embodiment is a further description of the method for cleaning and patrolling the mobile machine room cleaning and patrolling device described in Specific Embodiment 1. It also includes a wireless charging receiving device and a wireless charging transmitting device. The wireless charging receiving device The device is arranged in the housing of the cleaning robot for receiving radio waves sent by the wireless charging sending device.

[0040] The mobile machine room cleaning and inspection device described in this embodiment realizes radio wave charging, avoiding the problem of needing regular manual charging. The cleaning and patrolling device in the mobile computer room can be charged wirelessly when it is stationary, which improves the automation of the cleaning device.

specific Embodiment approach 3

[0041] Specific Embodiment 3. This embodiment is a further description of the method for cleaning and patrolling the mobile computer room cleaning and patrolling device described in the specific embodiment 1 or 2. The tracking module 6 is realized by using a TCRT5000 infrared reflective proximity switch sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com