Heat-fluid fabric cool feeling test equipment and test method

A test equipment and heat flow sensor technology, which is applied in the direction of material thermal development, textile and papermaking, textile material inspection, etc. Skin and other problems, to achieve the effect of convenient and fast testing process, easy to analyze and calculate and save the whole process data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1: Dual heat-flow fabric cool feeling test equipment

[0052] like figure 1 As shown, the dual-heat-flow type fabric cool feeling test equipment includes a host computer 1, a computer 2, a probe 3 connected to the host computer 1 through a cable, and an experimental bench 6. The experimental bench 6 is provided with a thermal insulation board 5. The fabric sample 4 is placed on top, and the thermal insulation board 5 is covered with a thermal insulation glass cover 7; the thermal insulation panel 5 is used to prevent heat from being transmitted from the vertical direction of the fabric, and the thermal insulation glass cover 7 is used to cover the fabric sample 4 and the thermal insulation panel. 5. It is isolated from the outside world to avoid the influence of unstable factors such as airflow during the test.

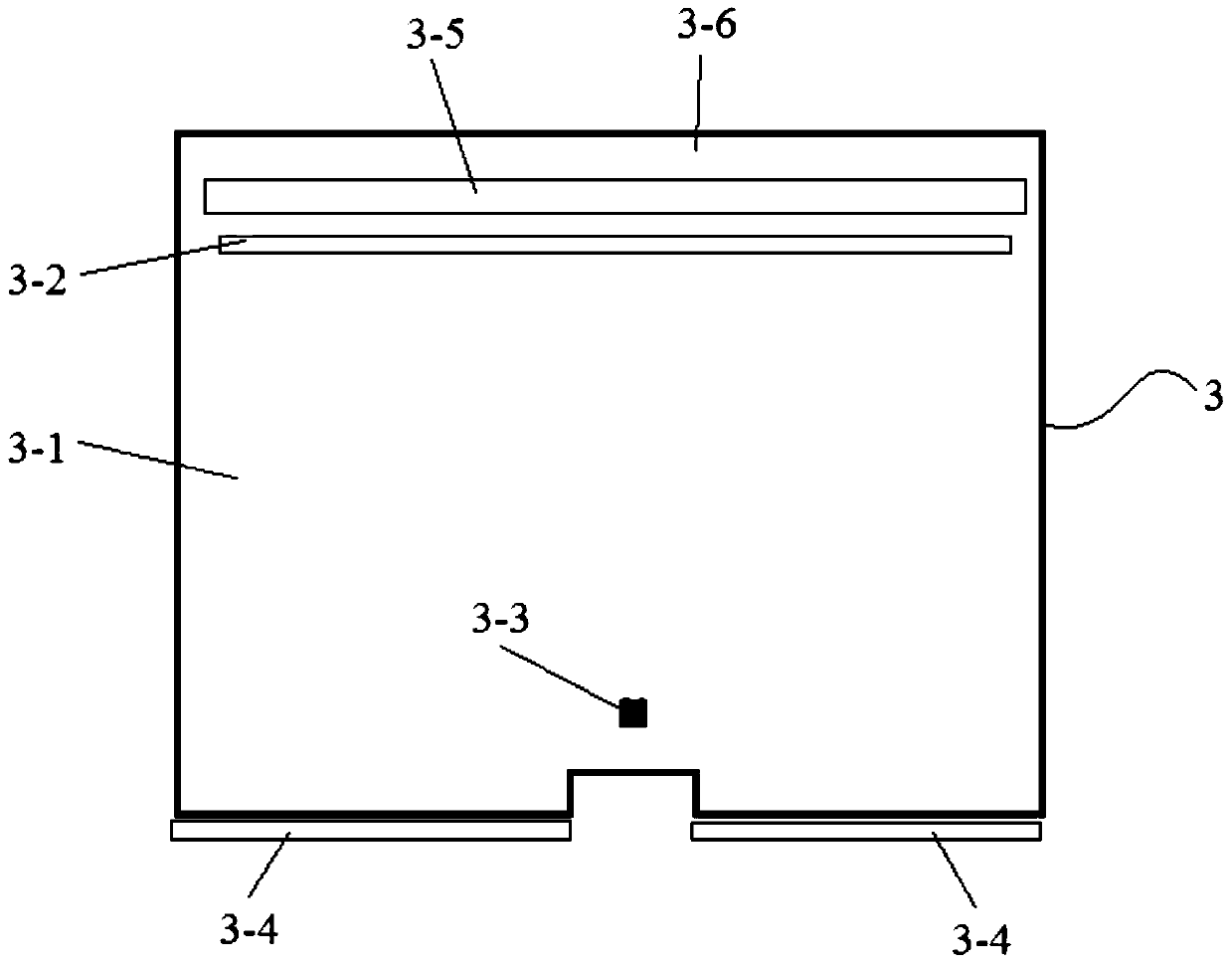

[0053] The probe 3 is the core test component, such as figure 2 As shown, including the aluminum frame 3-1, a constant temperature heat source 3-2 a...

Embodiment 2

[0061] Embodiment 2: Single heat flow type fabric cooling feeling test equipment

[0062] The structure of the single-heat-flow fabric cool feeling test equipment is the same as that of Embodiment 1 except for the probe.

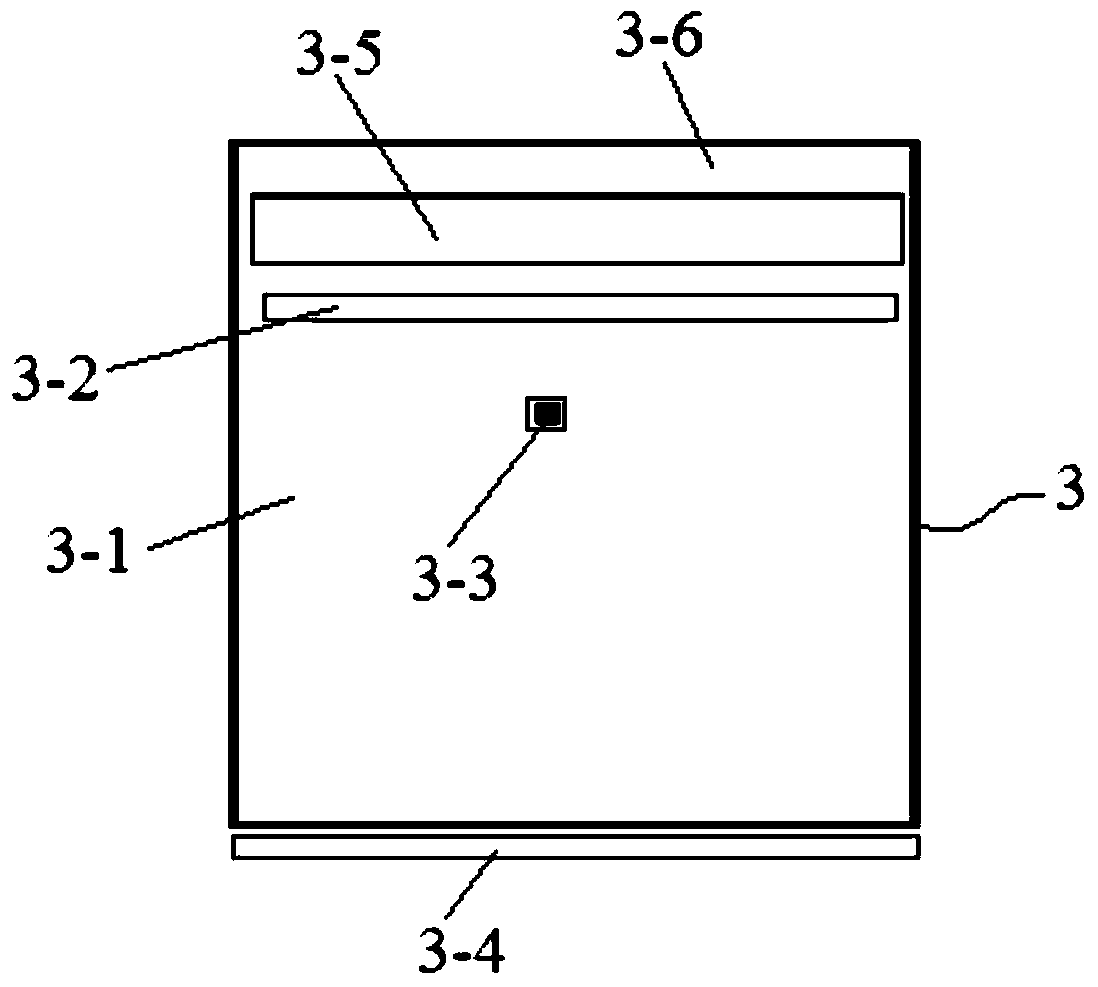

[0063] One heat flow sensor 3-4 is set in the single heat flow fabric cool feeling test equipment, such as image 3 As shown, the size of the heat flow sensor 3-4 is 50 mm×100 mm, and the size of the bottom surface of the probe 3 is the size of the heat flow sensor 3-4.

[0064] like image 3 As shown, the single heat flow sensor probe is made of a solid aluminum frame 3-1 processed from aluminum, so that the aluminum frame 3-1 becomes a high thermal conductivity constant temperature regenerator, and the silica gel heating sheet is placed on a constant temperature heat source 3-2. In the groove hollowed out in advance on the aluminum frame 3-1, the thermal insulation material 3-5 is covered on the constant temperature heat source 3-2, and then the aluminum c...

Embodiment 3

[0065] Embodiment 3: Integrated fabric cooling sensation testing equipment

[0066] like Figure 7 As shown, the integrated fabric cooling feeling test equipment adopts an intensive and simplified form, and the probe 3 and the host 1 are made into a compact and integrated instrument. The miniaturized intelligent PID temperature control meter 1-2, the Bluetooth data acquisition card 8 and the solid state relay are compactly designed and installed in one casing to realize the temperature control function of the host and the functions of Bluetooth data collection, storage and curve display. Specifically, a heat flow sensor 3-4, a silica gel heating sheet as a constant temperature heat source 3-2, a thermal insulation material 3-5, an intelligent PID temperature control meter 1-2, and a Bluetooth data acquisition card 8 are integrated in the casing. Only one power cord is needed to connect with the outside, and functions such as data collection, storage, and curve demonstration a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com