Wireless sensor module

A sensor module and sensor technology, applied in the direction of instruments, scientific instruments, signal transmission systems, etc., can solve the problems of no state monitoring solution, less application of state monitoring, difficult access and wiring, etc., to improve signal acquisition, good The effect of signal coupling and good signal acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

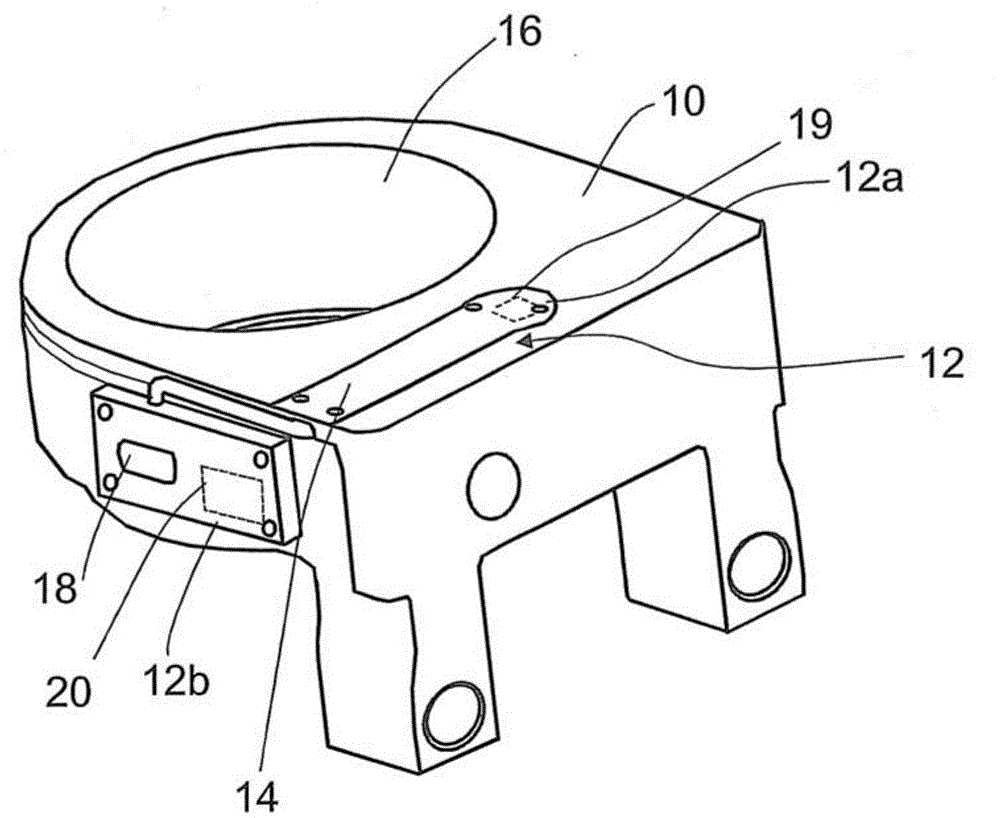

[0025] figure 1 There is a bearing housing 10 which is a continuously cast bearing covered with a metal plate 14 and equipped with a sensor module 12 according to the invention. The bore 16 of the housing 10 is configured to accommodate the outer ring of a continuously cast bearing which is monitored by a monitoring unit (not shown) according to the invention.

[0026] The sensor module 12 comprises an inner part 12a embedded in the main steel of the bearing housing 10 and an outer part 12b comprising an antenna 18 of a wireless transceiver 19 and a thermoelectric generator formed for harvesting energy from the local environment. Energy Harvesting Circuit 20.

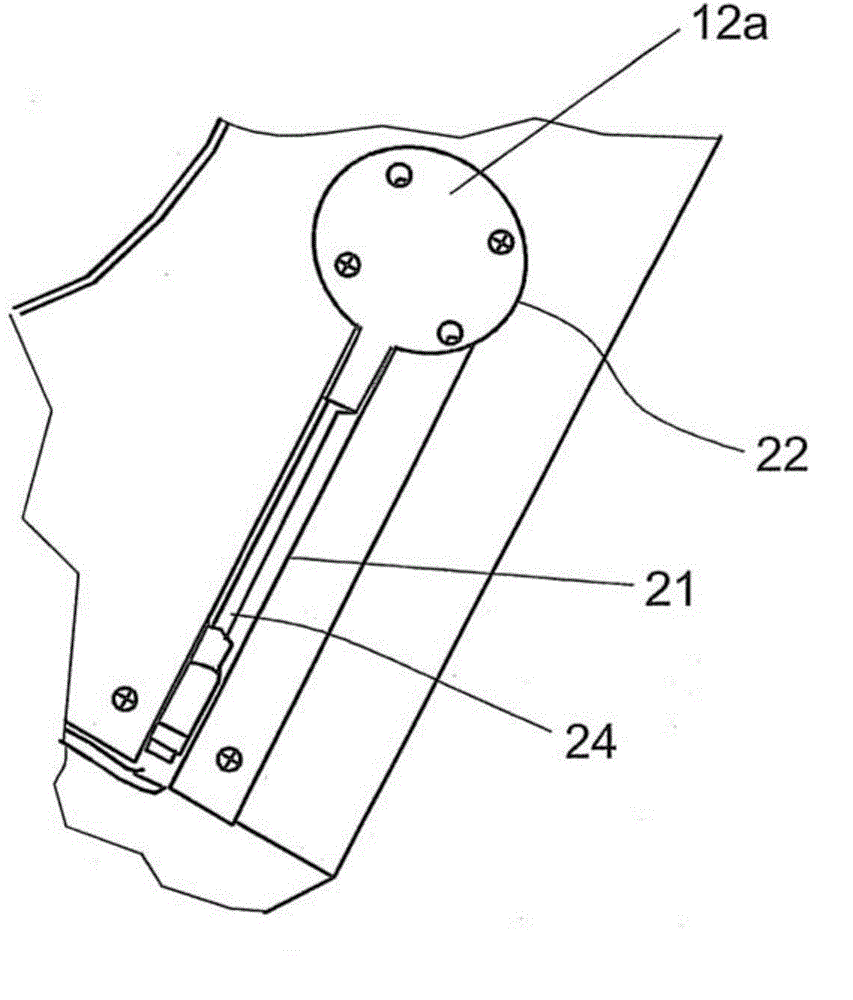

[0027] figure 2 After removing the metal plate 14 figure 1 Detail drawing of the bearing housing. The groove 21 on the upper surface of the bearing housing 10 connects the hole 22 accommodating the cylindrical inner part 12a, the outer part 12b and the guide cable 24 connecting the parts 12a, 12b, wherein the cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com