Host machine of novel oil injection sliding vane air compressor

A technology of air compressors and sliding vanes, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of low volumetric efficiency, long suction path, and large suction resistance, and achieve high volumetric efficiency and suction Short air path and low inhalation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

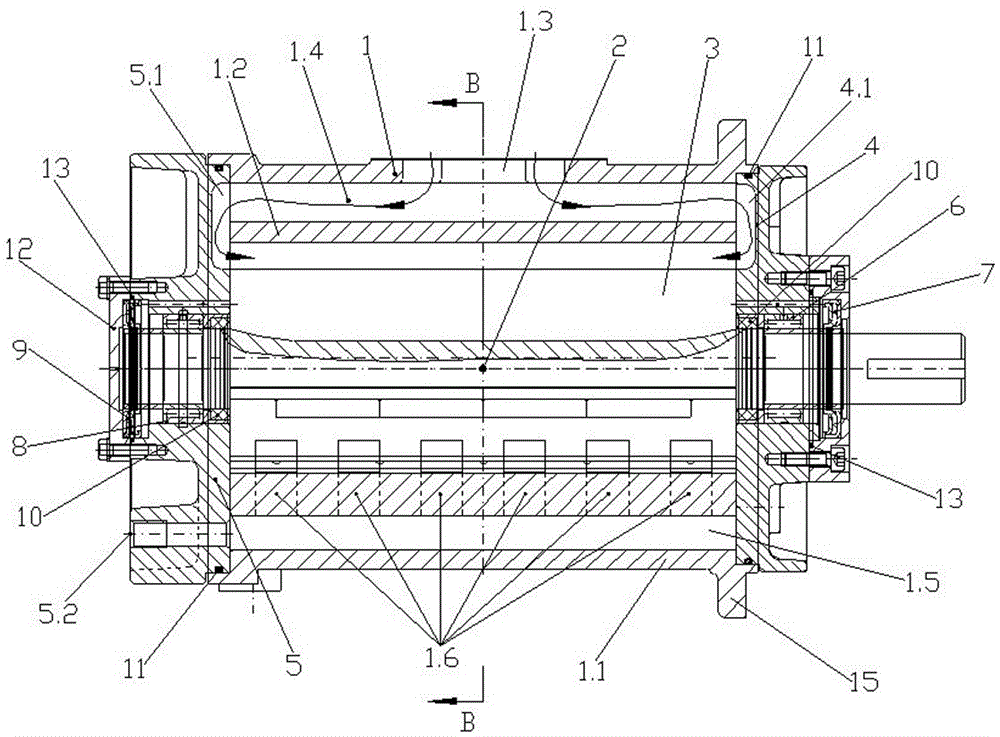

[0031] In the preferred embodiment provided by the present invention, a new oil-injected sliding vane air compressor main body includes a cylinder 1, a rotor 2 and a sliding vane 3;

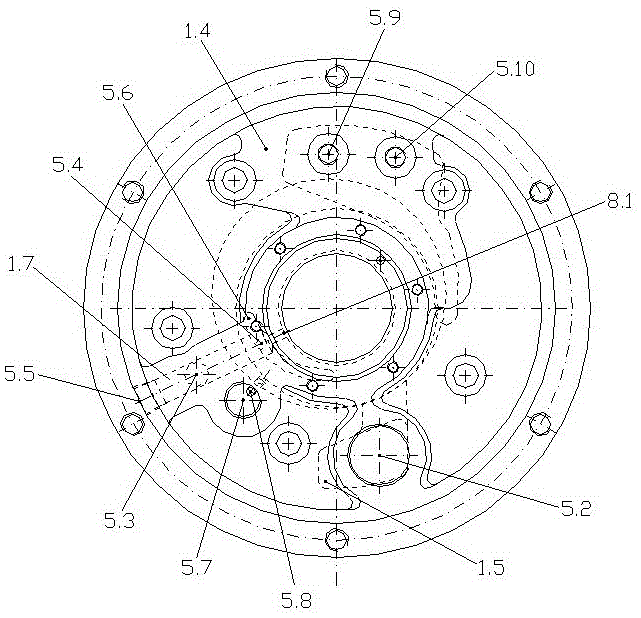

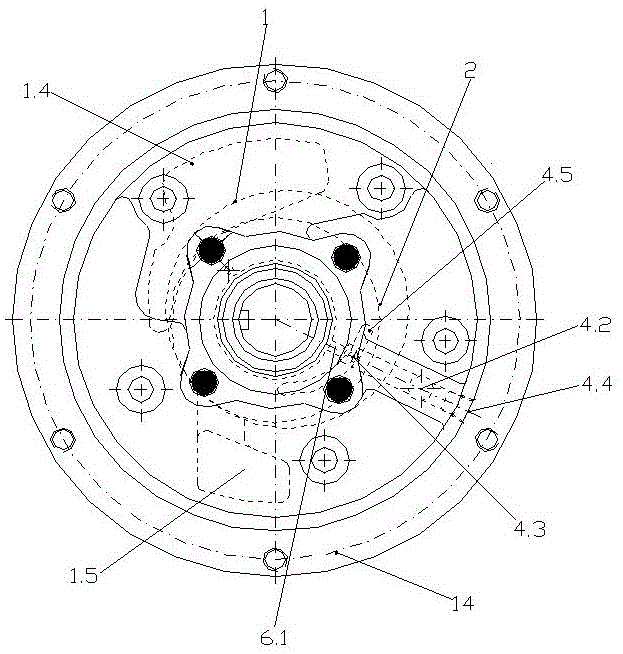

[0032] Such as figure 1 As shown, the above-mentioned cylinder 1 includes a casing 1.1 and an interlayer 1.2 arranged inside the casing 1.1. The bottom end of the casing 1.1 is provided with a mounting foot 15, and the casing 1.1 is also provided with a radial air inlet 1.3, and the interlayer 1.2 The top and bottom ends of the top and bottom of the casing are respectively provided with an axially penetrating air int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com