Method for Alleviating Pitting Corrosion on Tooth Surface of Wind Turbine Gearbox

A technology of wind turbines and gearboxes, which is applied in the control of wind turbines, wind turbines, wind power generation, etc., and can solve problems such as reducing the service life of gearboxes, pitting corrosion of gearboxes, and damage to the internal structure of gearbox transmission systems. Reduce tooth surface pitting, prevent frequent work, and be easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

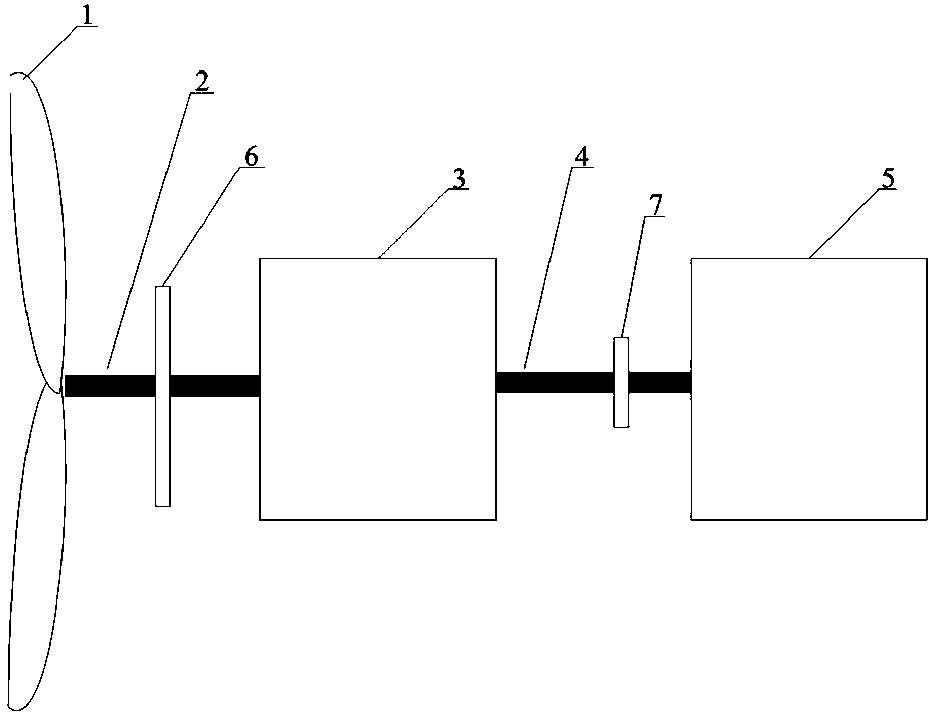

[0015] The present invention can reduce the tooth surface pitting of the gear box of the wind power generator through an intelligent braking method, and its realization structure is as follows: figure 1 As shown, the wind generator includes a wind wheel 1 , a low-speed shaft 2 , a gearbox 3 , a high-speed shaft 4 , and a generator 5 . The feature of the present invention is that a low-speed brake 6 is set on the low-speed shaft 2, and a speed detector 7 is set on the high-speed shaft 4. The working state of the brake 6 is controlled by the automatic control system.

[0016] like figure 2 As shown, the smart brake workflow is as follows:

[0017] When the unit is shut down, the brake is put into operation to stop the wind wheel from rotating.

[0018] When the wind speed changes, the wind rotor will start to rotate when the torque of the wind rotor is greater than the braking torque. When the speed of the high-speed shaft increases to V 2 When the low-speed shaft brake is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com