Opposed mixed-stroke mixed-stroke piston engine

A piston engine and opposed piston technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of insufficient exhaust and ventilation, long connecting rods, etc., and achieve full combustion, low power loss, and fast heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

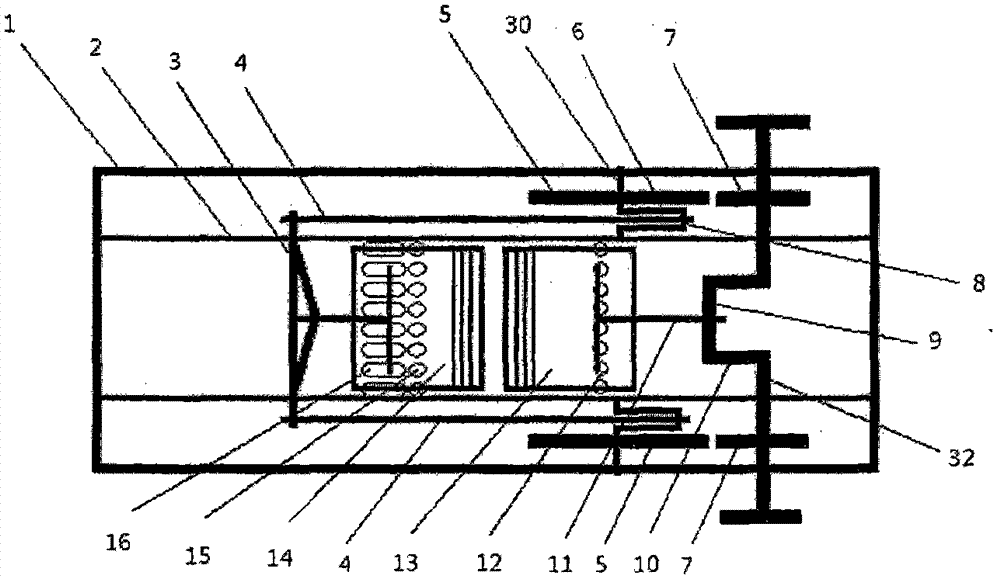

[0027] exist figure 1Among them, the opposed mixed-stroke mixed-stroke piston engine connecting the outer piston is a T-shaped connecting rod. An outer piston (14) of the two opposed pistons in the engine cylinder passes through the T-shaped connecting rod (3), the coaxial connecting rod (4) and the inner cylinder wall (2) and outer cylinder fixed on both sides of the cylinder block. The wall (1) has the functions of the gear and the crankshaft, is a combination of the crankshaft and the gear, and is connected to the rocker gear shaft (30) for mixed-range and mixed-range transmission; the other opposed inner piston (13) passes through the inner Piston connecting rod (11), crankshaft (32), crankshaft gear (7) and the gear (5) of the rocker arm gear shaft engage and drive; the gear (5) on the rocker arm gear shaft and the gear (7) on the crankshaft are Two large gears and pinion gears with different diameters and numbers of teeth mesh with each other for transmission or change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com