Radial rim sealing structure with damping holes and flow guide blades

A technology of guide vanes and sealing structure, applied in the direction of preventing leakage, engine components, machines/engines, etc., can solve problems such as limited effect, and achieve the effects of improving sealing performance, improving economy, and improving heat transfer stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and technical principles.

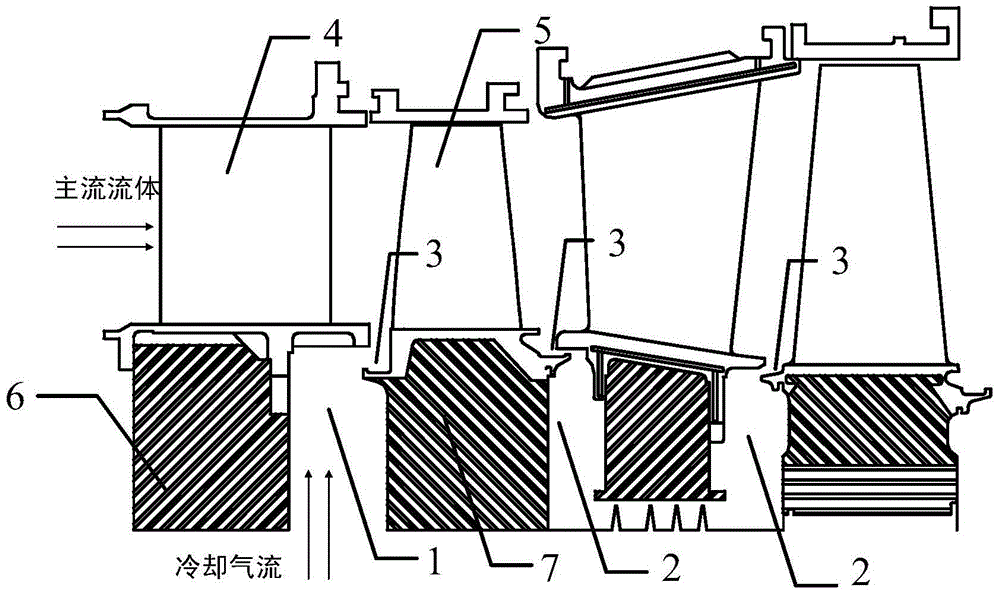

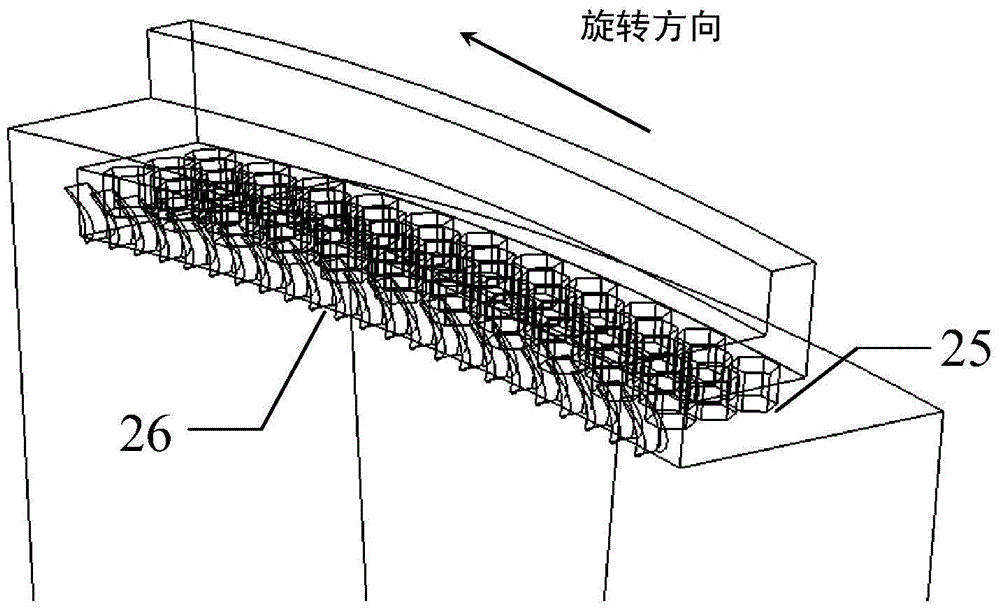

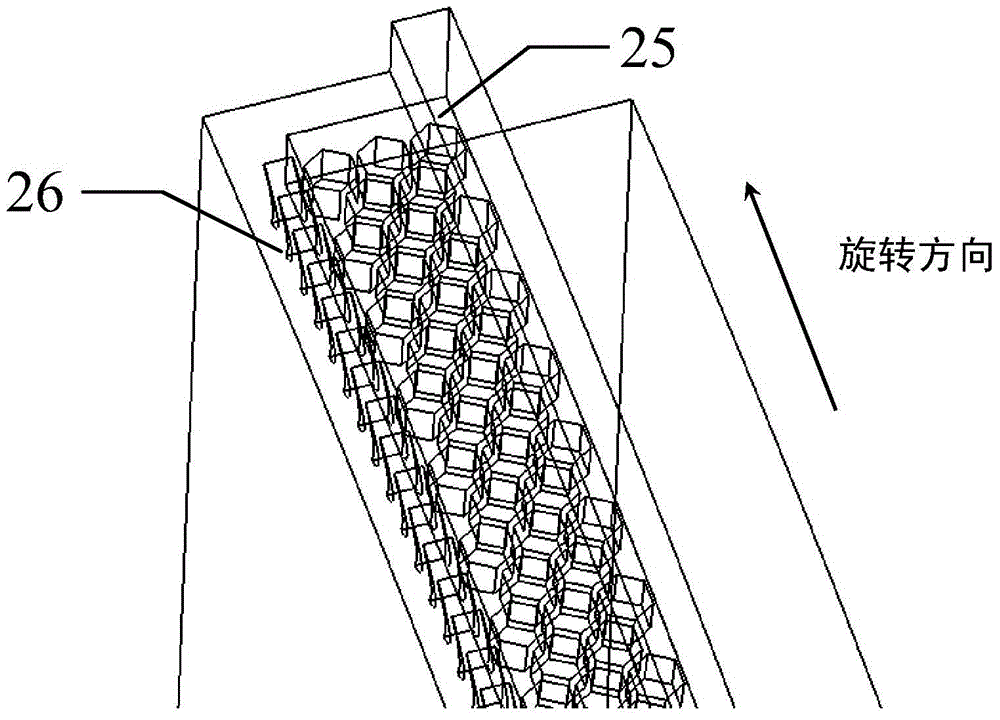

[0034] see Figure 1 to Figure 5 , a radial rim seal structure with damping holes and guide vanes in the present invention, the radial rim seal structure 3 is arranged in the gas turbine rotary-stationary disc cavity 1 or in the gas turbine rotary-rotary disc cavity 2 , including external teeth 8 and radial inner teeth 11 that cooperate with each other; wherein, a number of damping holes 25 are evenly opened on the upper end surface 9 of the inner teeth of the radial inner teeth 11 in the circumferential direction, and in the radial direction of the inner teeth of the radial inner teeth 11 A number of guide vanes 26 are evenly arranged on the circumference of the end face 10 .

[0035]Specifically, referring to Figs. 2 and 3, different from the traditional radial rim seal, the damping radial rim seal of the present invention has stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com