Reserved deformation stage-type grading yielding gob-side entry retaining gob-side filling body and construction method thereof

A technology of filling body and stage, which is applied in the direction of filling, earthwork drilling, safety devices, etc., can solve the problems of high cost, large amount of unit block prefabrication, and large amount of underground masonry construction, and achieves convenient and easy connection. The effect of construction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Taking a certain mine as an example, the construction method of the filling body beside the gob-side retaining roadway of the present invention will be described by way of example.

[0101] Known geological conditions:

[0102] The 1302 working face of a certain mine mines the third lower coal seam, the full height is mined at one time, the thickness of the mined height is h=6.2m, the strike length is 1600m, and the inclination length is 180m;

[0103] The roof lithology from bottom to top is: siltstone (1.09m), fine sandstone (9.81m), coarse sandstone (17m), fine sandstone (2.45m), claystone (16.12m), fine sandstone (38m) .

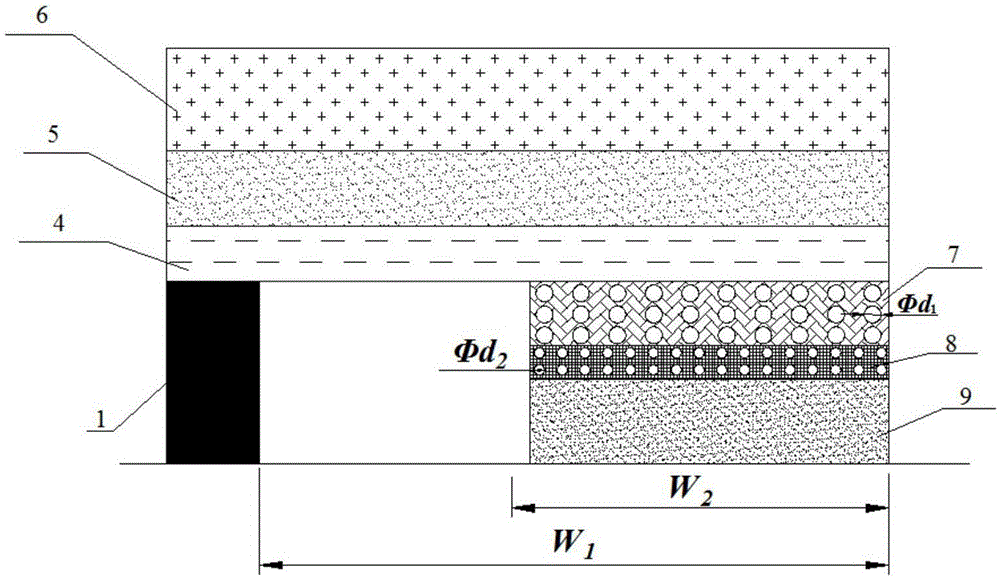

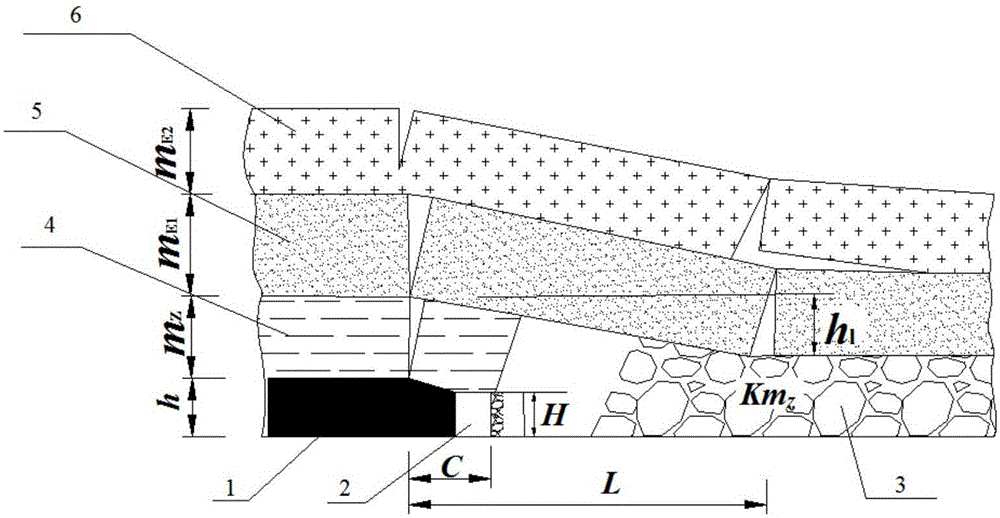

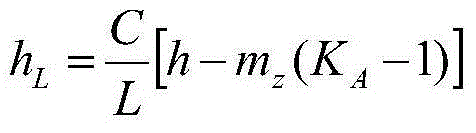

[0104] According to the existing mine pressure observation results, the main mine pressure parameters of the 1302 working face are as follows: figure 2 Shown:

[0105] Thickness of direct roof 4 (caving layer) m z =11m;

[0106] The distance from the roadside filling body 9 to the fracture line at the end of the old top rock beam 5 is C=6.5m; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com