Local filling mining method for longwall face along strike of steeply dipping seam

A mining method and working face technology, applied in filling, ground mining, mining equipment, etc., can solve problems such as low production efficiency of working face, poor stability of "support-surrounding rock" system, difficult roof management, etc., and achieve layout design Reasonable, easy to implement, and the effect of increasing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

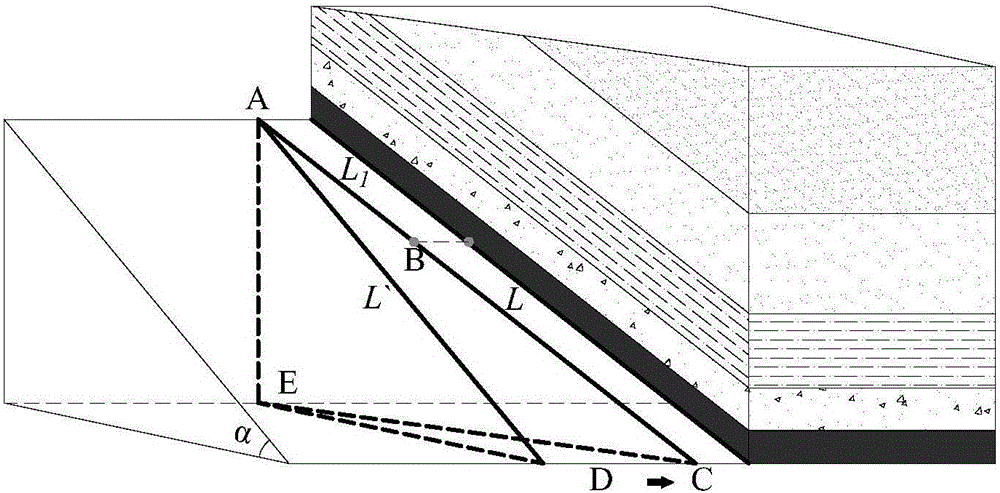

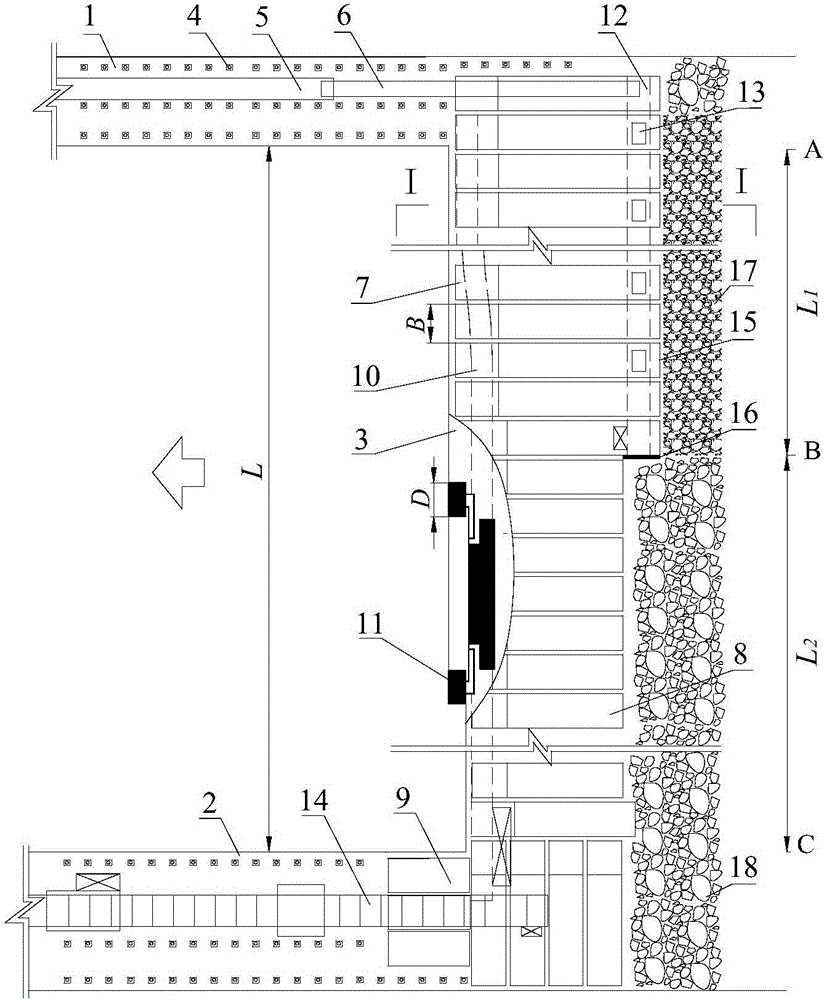

[0061] The local filling mining method for the longwall working face of a large dip angle coal seam (a coal seam with a dip angle within the range of 35° to 55°) includes the following steps:

[0062] (1) Determine the layout and parameters of the local filling face

[0063] (11), select a pseudo-inclined longwall working face as the actual mining face of the high-inclination coal seam, the angle between the pseudo-inclined longwall working face and the true inclined working face is 0°,

[0064] (12) Partially fill the upper area of the actual mining face, the inclination length L of the actual mining face is 200m, and the length of the filling area of the actual mining face is L 1 80m;

[0065] (2), mining coal seam

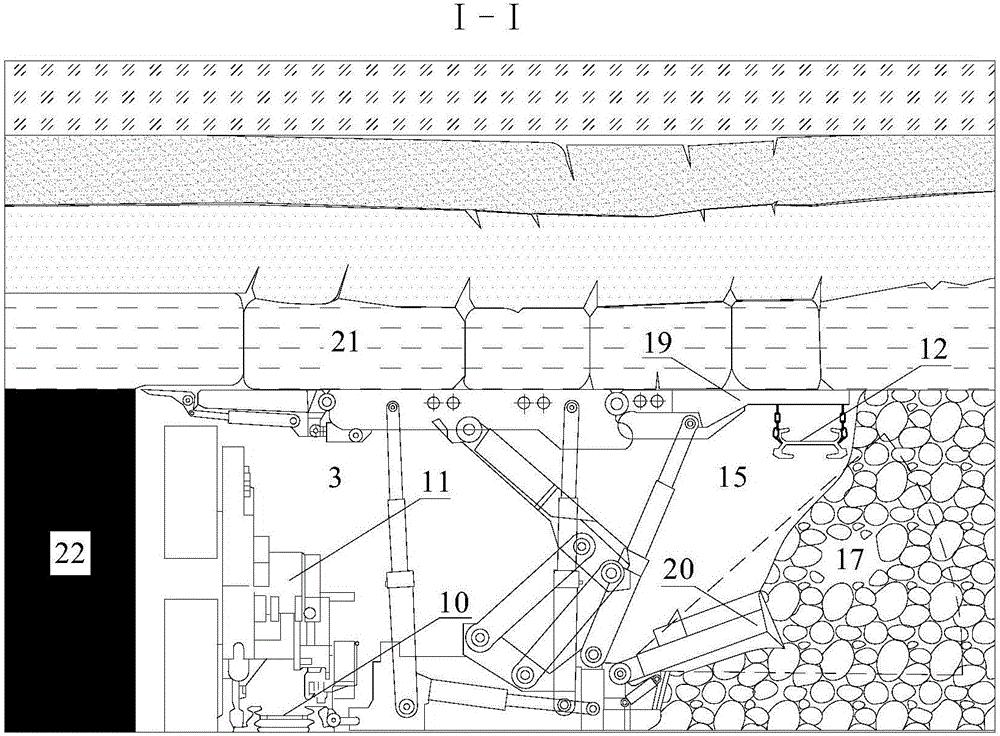

[0066] (21), adopt comprehensive mechanized partial filling mining method mining, take the pseudo-incline longwall working face determined in step (1) as the actual mining working face, and carry out working face mining with the direction of the large dip ...

specific Embodiment 2

[0076] Roughly the same as the specific embodiment 1, the only difference is

[0077] In step (11), the included angle between the pseudo-inclined longwall working face and the true inclined working face is 7°;

[0078] The inclination length L of the actual mining face in step (12) is 133m, and the filling area length L of the actual mining face is 1 is 53.2m;

[0079] In step (22), the support of the working face adopts six-column support in the filling area to support the middle hinged double pushing device to fill the hydraulic support; in the non-filling area, the hydraulic support is used;

[0080] Use gangue and fly ash as solid filling materials, the mass ratio of gangue and fly ash is 1:0.3, the particle size of gangue is less than 30mm, the moisture content of solid filling material is 25%, and the filling rate of the filling area is not less than 90%.

specific Embodiment 3

[0081] Roughly the same as the specific embodiment 1, the only difference is

[0082] In step (11), the included angle between the pseudo-inclined longwall working face and the true inclined working face is 5°;

[0083] In step (12), the inclination length L of the actual mining face is 150m, and the filling area length L of the actual mining face is 1 60m;

[0084] In step (22), the support of the working face adopts six-column support in the filling area, and the middle hinged double push device is used to fill the hydraulic support; in the non-filling area, a four-column support shielding hydraulic support is used;

[0085] Use gangue and fly ash as solid filling materials, the mass ratio of gangue and fly ash is 1:0.3, the particle size of gangue is less than 30mm, the moisture content of solid filling material is 23%, and the filling rate of the filling area is not less than 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com