A method for lifting and leveling the floor on soft soil foundation and its lifting structure

A soft soil foundation and floor technology, which is applied in the direction of basic structure engineering, building maintenance, building construction, etc., can solve the problems that the floor cannot be reinforced to provide sufficient support, the construction difficulty is increased, and the construction period is long, etc. Reduced construction waste, safe and convenient construction, and low project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

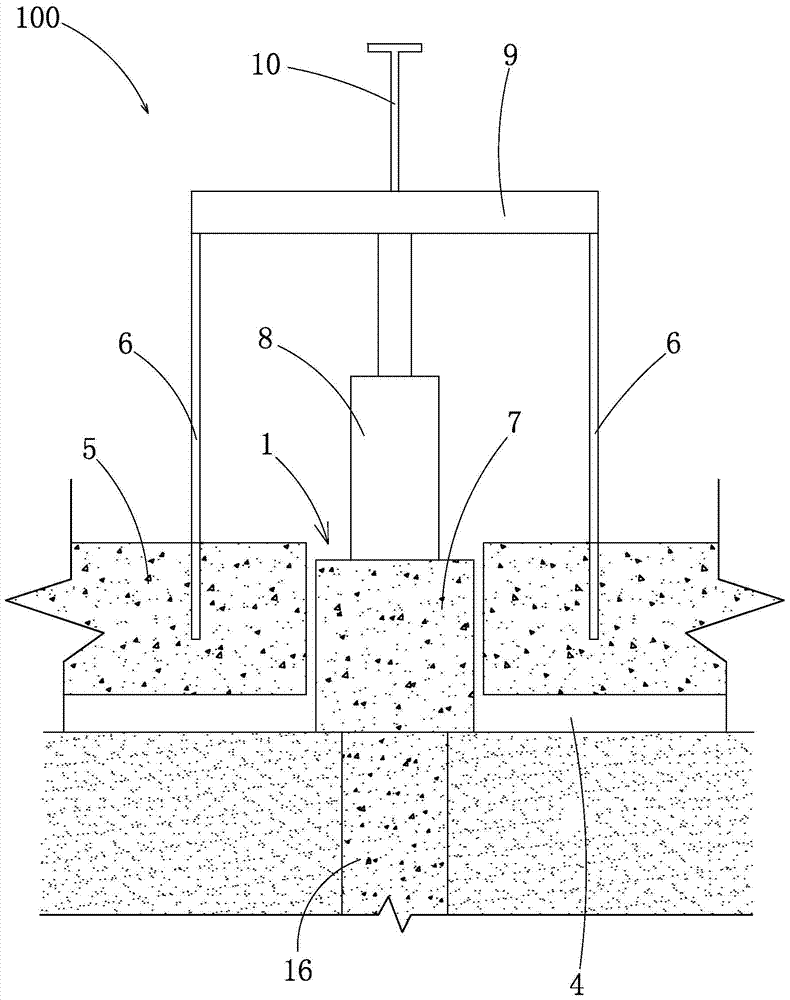

[0036] This embodiment provides a method for lifting, leveling and repairing the floor on a soft soil foundation, see figure 1 , due to the soft soil base 21 under the floor 5, and the soft soil base 21 is a hard soil layer (as figure 2 As shown), the present invention makes full use of the hard soil layer to repair the subsidence caused by the soft soil base 21 under the floor 5 to meet the requirements of flatness. The method specifically includes the following steps 1 to 6:

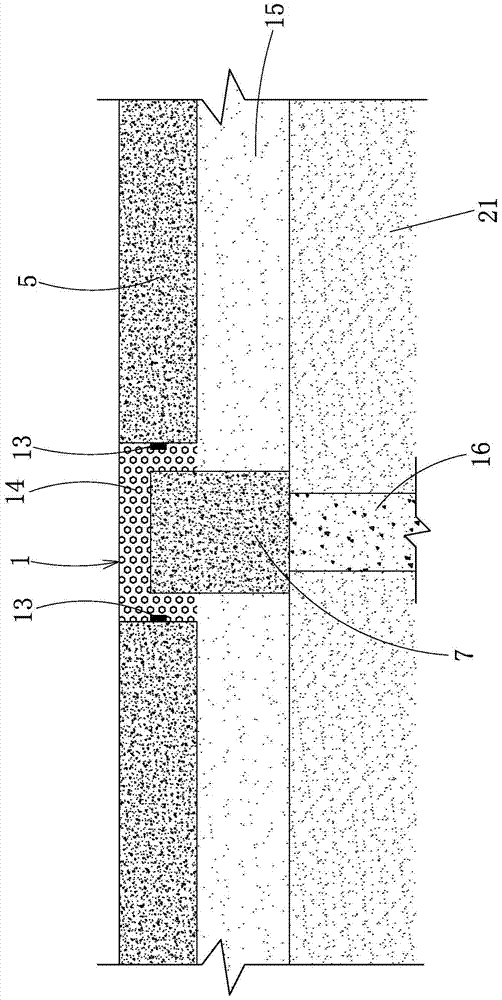

[0037] Step 1: Drill lifting holes 1 in at least one place of the floor 5, separate the concrete base 7 within the range of each lifting hole 1 from the surrounding ground 5 and take it out for later use. The concrete base 7 can be used as a jack 8 in the later stage (details See below), the lifting hole 1 is preferably drilled with a geological drilling rig.

[0038] Step 2, drill vertically downwards in each lifting hole 1 and insert a reinforcement pile 16 inserted into the soft soil base 21 under...

Embodiment 2

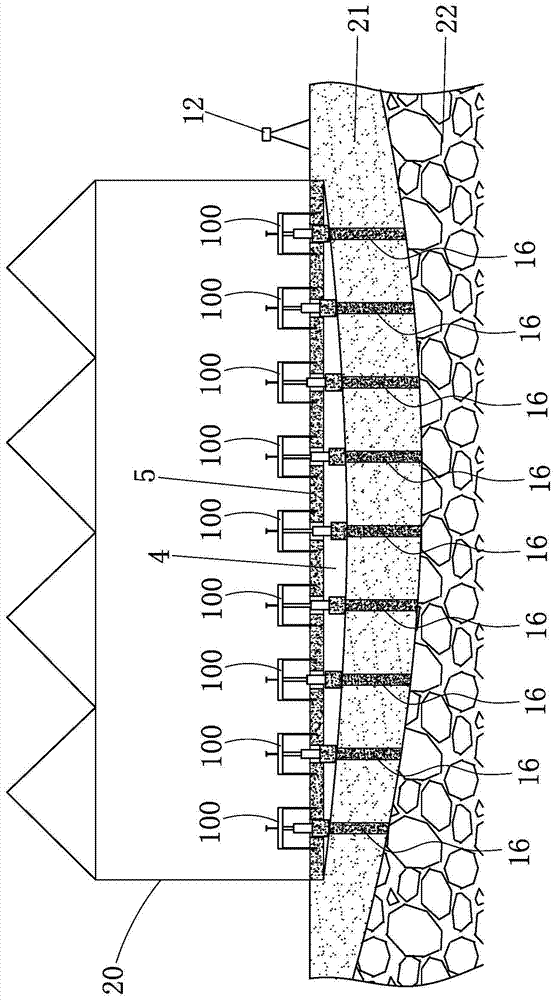

[0045] Such as figure 2 As shown, when the area of the warehouse 20 and the floor 5 below it is large, the settlement depth of the large-area floor 5 is uneven, and it is in the shape of a pot with a deep middle and a shallow edge, requiring multiple lifting structures 100 to work together to level It is more difficult. On the basis of Example 1, this example also provides a method for lifting, leveling and repairing a large-area floor, which specifically includes the following steps 1 to 6:

[0046] In step 1, a plurality of lifting holes 1 are evenly drilled in the floor 5, so that the concrete base 7 within the scope of the lifting holes 1 is separated from the surrounding floor 5 and taken out for use. The lifting holes 1 are preferably arranged in a square or an equilateral triangle on the floor 5, such as Figure 4 As shown, the spacing is 2-5m.

[0047] Step 2, drill vertically downwards in each lifting hole 1 and insert a reinforcement pile 16 inserted into the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com