Impeller connecting assembly and washing machine

A technology for connecting components and pulsators, applied in the field of washing machines, can solve the problems of inconvenient disassembly or installation of screws, easy damage in disassembly and assembly, affecting the service life of the washing machine, etc., and achieves the effect of reducing the difficulty of disassembly, prolonging the service life and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

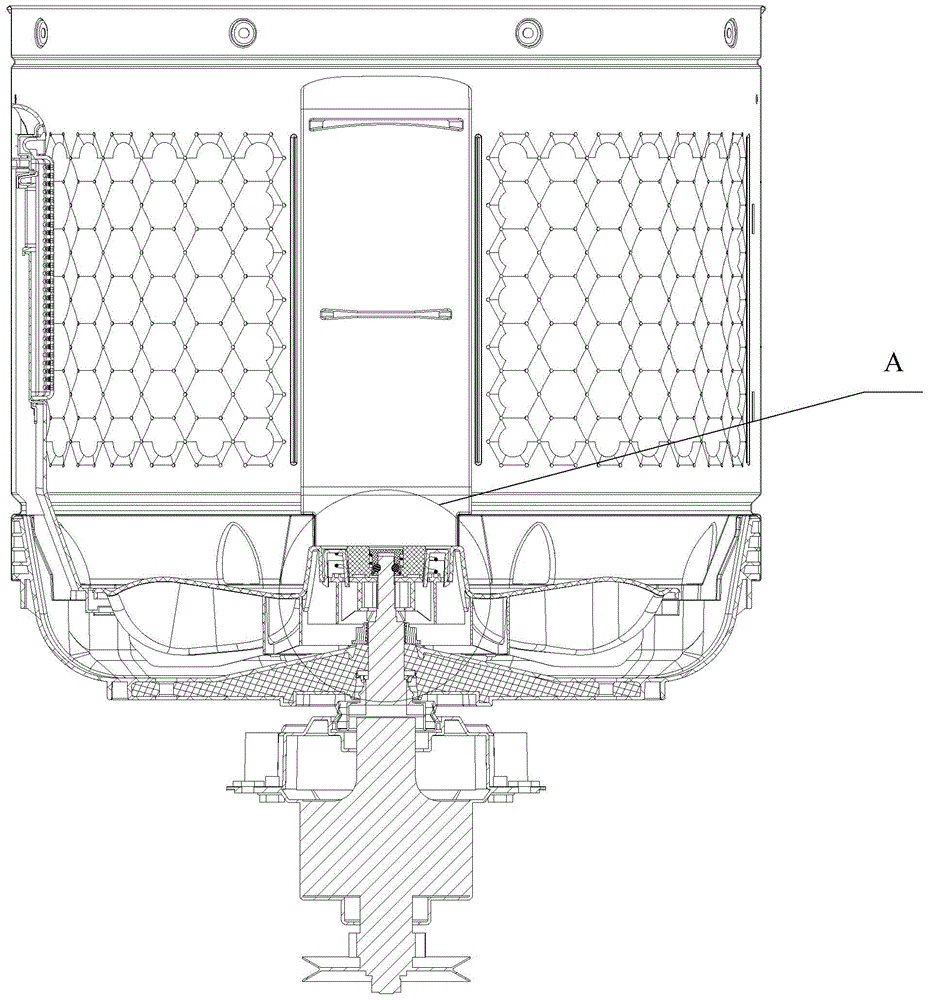

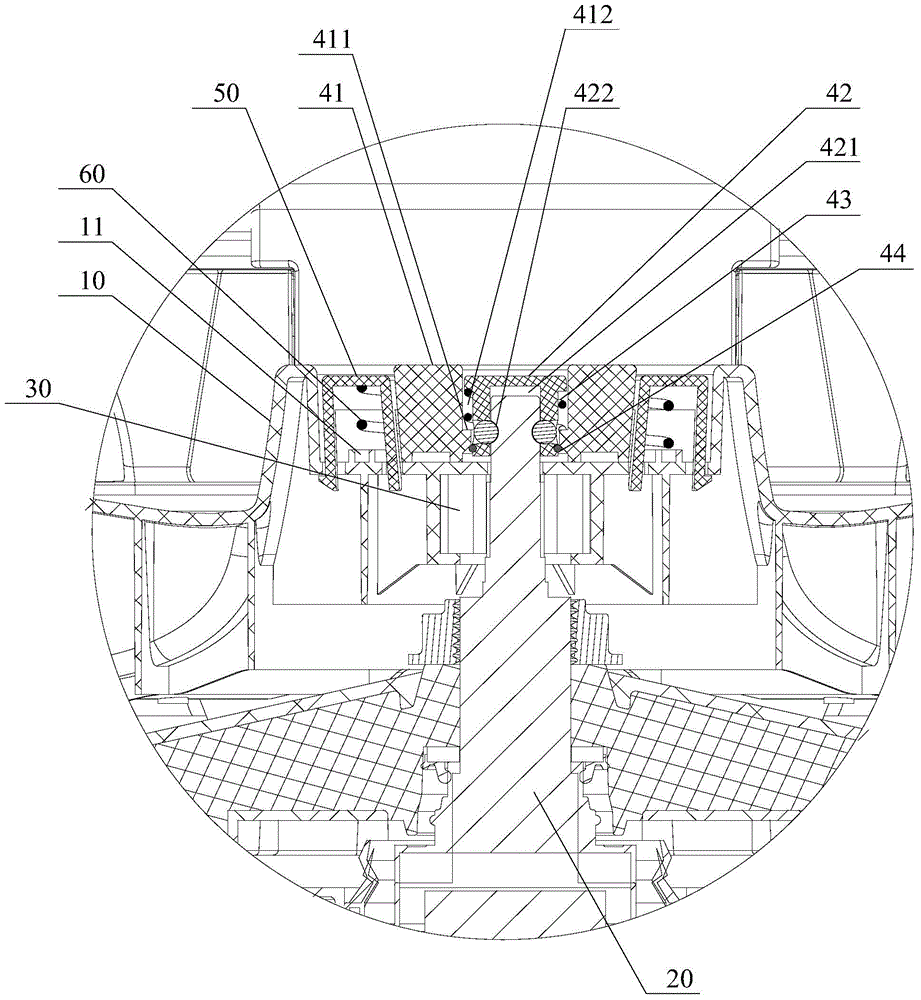

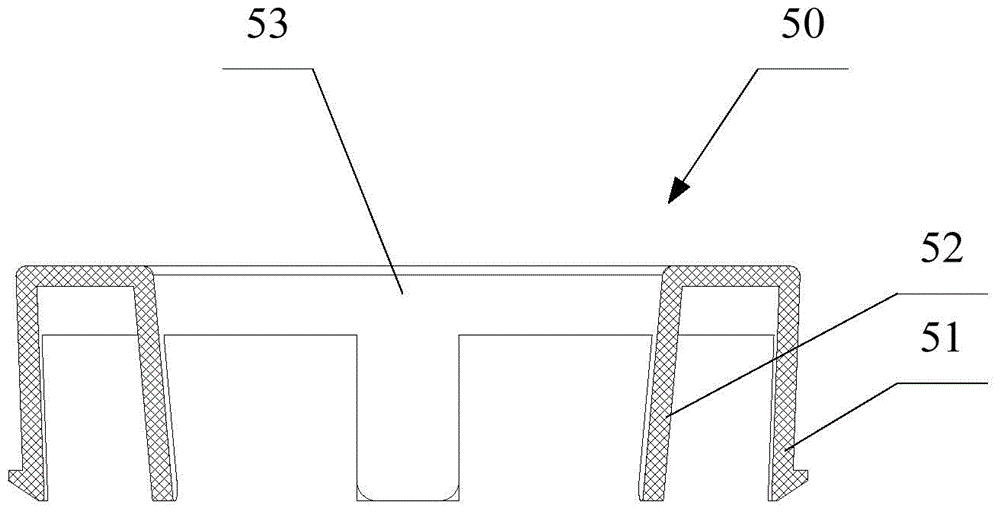

[0024] The invention provides a pulsator connection assembly, referring to Figure 1 to Figure 6 , in one embodiment, the pulsator connection assembly detachably connects the pulsator 10 to the rotating shaft 20, the pulsator connection assembly includes a spline 30 and a locking member, wherein the pulsator 10 is connected to the pulsator 10 through the spline 30 The rotating shaft 20 is connected, and the locking member is detachably and fixedly connected to the rotating shaft 20 , and abuts against the pulsator 10 to limit the axial movement of the pulsator 10 on the rotating shaft 20 .

[0025] The pulsator connection assembly provided by the embodiment of the present invention is mainly used in a pulsator washing machine to realize the fixing of the pulsator 10 and the rotating shaft 20 . In this embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com