Metal mask cooling device and metal mask evaporating device

A metal mask and cooling device technology, applied in vacuum evaporation coating, metal material coating process, sputtering coating, etc., can solve the problems of inconvenient installation and maintenance, untimely control, large temperature inertia, etc., and achieve installation and maintenance Convenience, timely temperature control, and high temperature control efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

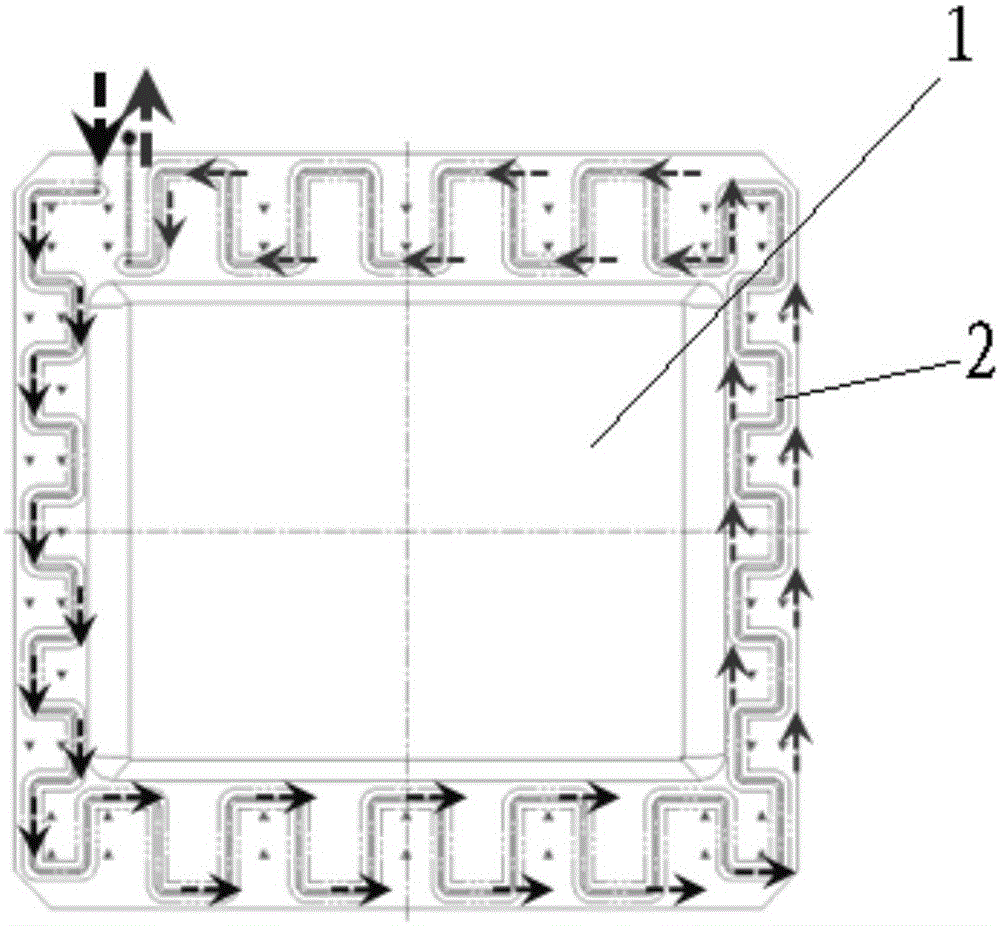

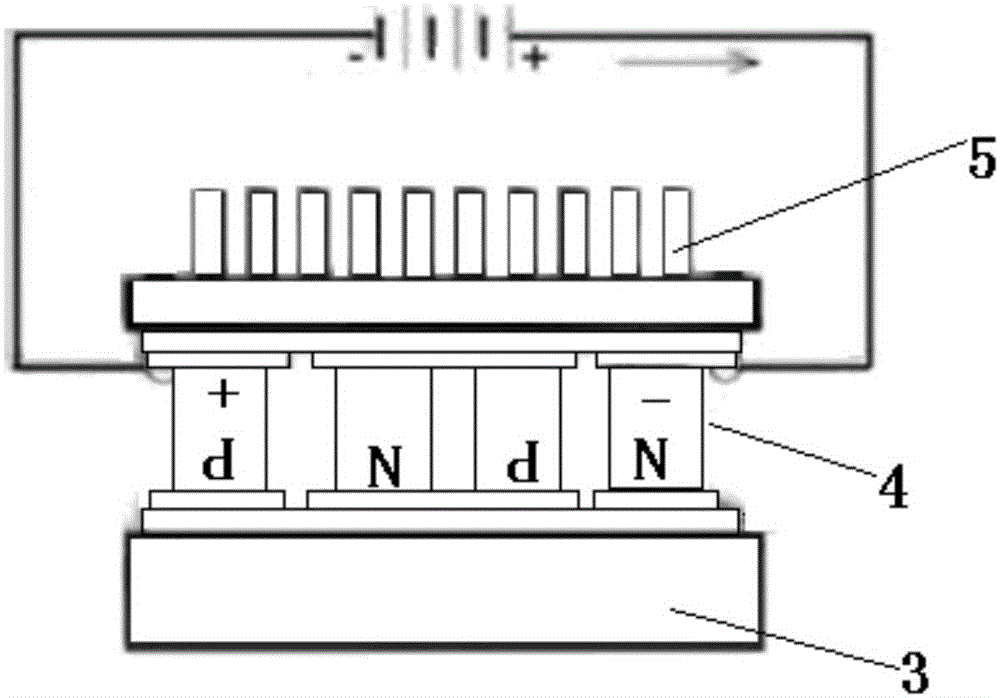

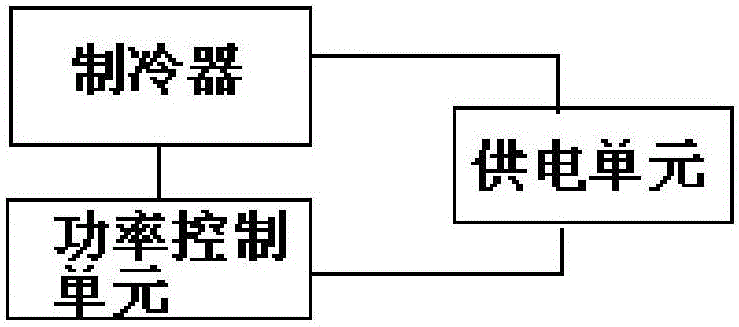

[0026] Such as figure 2 , image 3 and Figure 5 As shown, the metal mask 11 cooling device provided by the present invention includes a refrigerator 4, a power control unit, a power supply unit, and a magnetic board 10; the refrigerator 4 is attached to one side of the substrate 3, and the substrate 3 is attached to the substrate 3 The metal mask 11 on the other side is cooled; the magnetic plate 10 is arranged on the refrigerator 4 to adsorb the refrigerator 4 and the metal mask 11 on both sides of the substrate 3; the power control unit is connected to the refrigerator 4 to Control the refrigeration temperature of the refrigerator 4; the power supply unit is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com