1200MPa-grade cold-rolled annealed dual-phase steel and production method thereof

A technology of cold-rolled annealing and production methods, which is applied in the field of cold-rolled high-strength steel plates, can solve the problems of little successful production experience and high production difficulty, and achieve the effects of good bake hardening performance and continuous yield characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

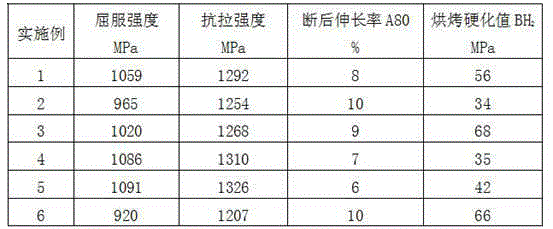

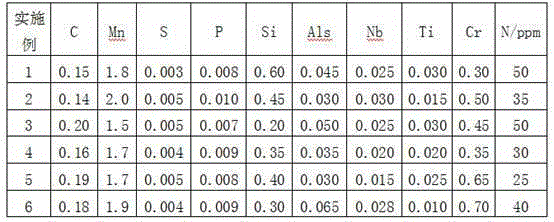

Examples

Embodiment 1

[0018] Embodiment 1: The production method of this 1200MPa grade cold-rolled annealed dual-phase steel adopts the following specific processes.

[0019] (1) Hot rolling process: the time in the furnace is 130 minutes, the soaking temperature of the slab is 1280°C, and the soaking time is 28 minutes; out of the furnace, the final rolling temperature is 875°C, the front cooling mode is adopted, and the coiling temperature is 550°C.

[0020] (2) Cold rolling annealing process: cold rolling reduction rate is 60%, the soaking temperature of the annealing step is 780°C, the rapid cooling start temperature is 630°C, the overaging temperature is 280°C, and the production process speed is 160m / min. The production process speed refers to the running speed of the steel strip in the continuous annealing furnace.

[0021] (3) Leveling process: the reduction rate is 0.5%, and a dual-phase steel with a thickness of 1.0 mm can be obtained after leveling.

Embodiment 2

[0022] Embodiment 2: The production method of the 1200MPa grade cold-rolled annealed dual-phase steel adopts the following specific processes.

[0023] (1) Hot rolling process: the time in the furnace is 120 minutes, the soaking temperature of the slab is 1280°C, and the soaking time is 30 minutes; out of the furnace, the final rolling temperature is 860°C, the front cooling mode is adopted, and the coiling temperature is 680°C.

[0024] (2) Cold rolling and annealing process: the cold rolling reduction rate is 55.0%, the soaking temperature of the annealing step is 820°C, the rapid cooling start temperature is 760°C, the overaging temperature is 300°C, and the production process speed is 125m / min.

[0025] (3) Leveling process: the reduction rate is 0.4%, and a dual-phase steel with a thickness of 1.3mm can be obtained after leveling.

Embodiment 3

[0026] Embodiment 3: The production method of the 1200MPa grade cold-rolled annealed dual-phase steel adopts the following specific processes.

[0027] (1) Hot rolling process: the time in the furnace is 128 minutes, the soaking temperature of the slab is 1275°C, and the soaking time is 32 minutes; out of the furnace, the final rolling temperature is 870°C, the front cooling mode is adopted, and the coiling temperature is 620°C.

[0028] (2) Cold rolling annealing process: cold rolling reduction rate is 50%, the soaking temperature of the annealing step is 800°C, the rapid cooling start temperature is 700°C, the overaging temperature is 260°C, and the production process speed is 105m / min.

[0029] (3) Leveling process: the reduction rate is 0.4%, and a dual-phase steel with a thickness of 1.5mm can be obtained after leveling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com