High-performance concrete expansive agent

A high-performance concrete and expansion agent technology, applied in the field of high-performance concrete expansion agent, can solve the problems of insufficient shrinkage compensation, inability to adapt to the development of concrete strength, low expansion rate, etc., to reduce shrinkage cracks, excellent anti-crack and anti-seepage properties, and the effect of preventing shrinkage cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

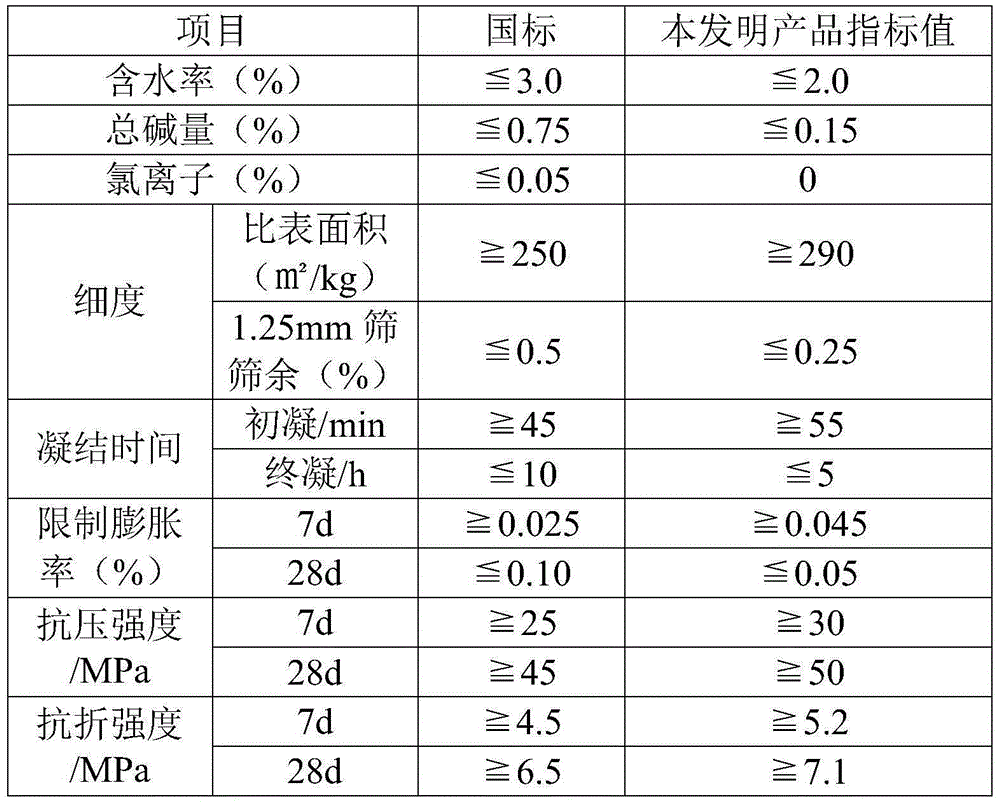

Image

Examples

Embodiment 1

[0017] 1. Weigh the following raw materials in parts by weight: 30 parts of calcium sulfoaluminate, 8 parts of sepiolite, 11 parts of polytetrafluoroethylene powder, 9 parts of pentaerythritol, 1 part of benzenediol, and 10 parts of glass fiber powder;

[0018] 2. First, mix the sepiolite with the particle size of 55nm and the polytetrafluoroethylene powder with the particle size of 16μm, start the forced mixer, stir for 5min to make it evenly mixed, then start the mixer, add sulfoaluminate after an interval of 1min Calcium, pentaerythritol, benzenediol and glass fiber powder; continue to stir for 40 minutes, stir evenly, and finally package, which is the finished product.

Embodiment 2

[0020] 1. Weigh the following raw materials by weight: 32 parts of calcium sulfoaluminate, 10 parts of sepiolite, 9 parts of polytetrafluoroethylene powder, 3 parts of pentaerythritol, 1 part of benzenediol, 8 parts of glass fiber powder;

[0021] 2. First, mix the sepiolite with the particle size of 65nm and the PTFE powder with the particle size of 13μm uniformly, start the forced mixer, stir for 5min to make it evenly mixed, then start the mixer, add sulfoaluminate after an interval of 1min Calcium, pentaerythritol, benzenediol and glass fiber powder; continue to stir for 40 minutes, stir evenly, and finally package, which is the finished product.

Embodiment 3

[0023] 1. Weigh the following raw materials in parts by weight: 35 parts of calcium sulfoaluminate, 12 parts of sepiolite, 7 parts of polytetrafluoroethylene powder, 5 parts of pentaerythritol, 2 parts of benzenediol, 7 parts of glass fiber powder;

[0024] 2. First, mix the sepiolite with the particle size of 75nm and the polytetrafluoroethylene powder with the particle size of 10μm uniformly, start the forced mixer and stir for 5min to make it evenly mixed, then turn on the mixer, add sulfoaluminate after an interval of 1min. Calcium, pentaerythritol, benzenediol and glass fiber powder; continue to stir for 40 minutes, stir evenly, and finally package, which is the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com