Draft beer filling machine

A filling machine and draft beer technology, applied in packaging, distribution devices, transportation and packaging, etc., can solve problems such as affecting beer drinking, slow filling speed, and more foam, saving manpower and material resources, low production costs, The effect of less foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

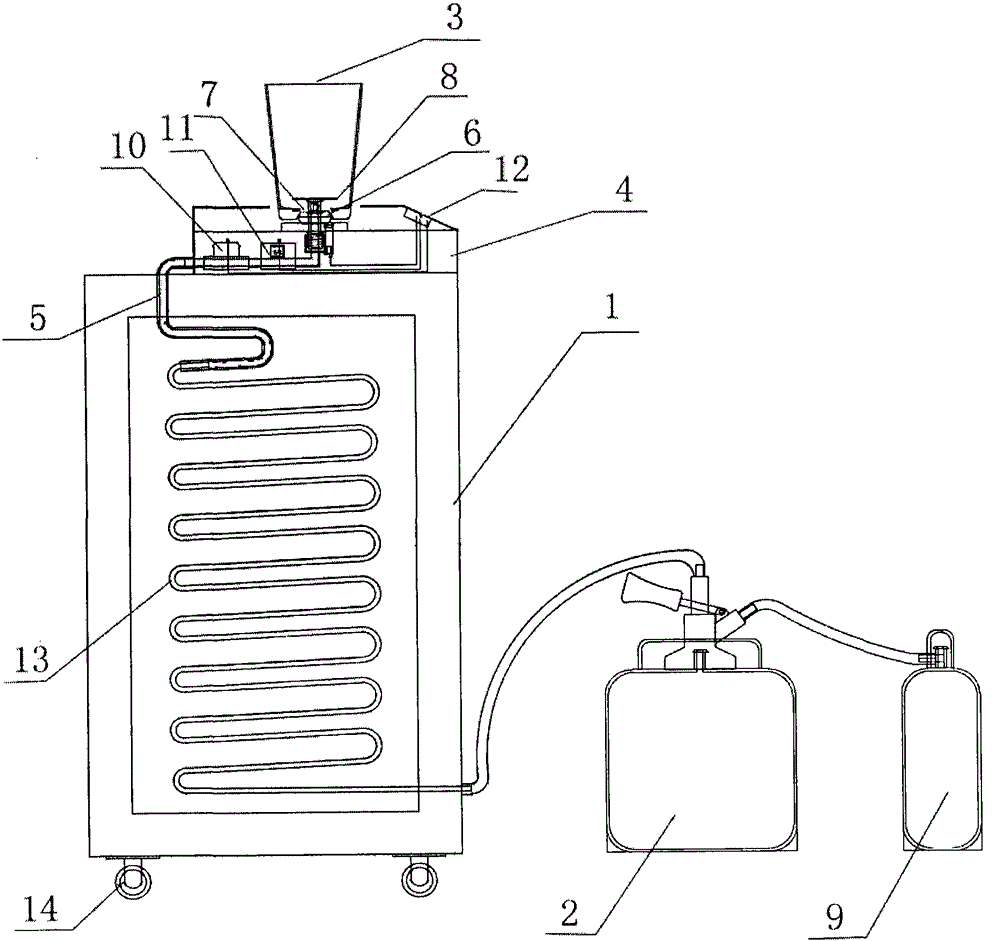

[0019] A draft beer filling machine, comprising a filling body 1, a beer keg 2, a beer mug 3 and a filling power device, the top of the filling body 1 is provided with a wine glass holder 4, and a beer cup holder 4 is installed inside the wine glass holder 4 The pipe 5 connected to the barrel 2, the end of the pipe 5 near the end of the wine glass holder 4 is connected with the filling head 6, the bottom of the beer glass 3 is provided with a filling through hole 7 corresponding to the filling head 6, and the filling through hole 7 A magnetic sealing plug 8 is installed on the top, the filling power device is a carbon dioxide gas tank 9, the beer keg 2 is connected to the carbon dioxide gas tank 9 through a hose, a solenoid valve 10 and a flow meter 11 are installed on the pipeline 5, and a wine glass holder 4 is installed on the outside The display control panel 12 connected with the solenoid valve 10 and the flow meter 11 is installed obliquely. The filling head 6 is made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com