A manufacturing process for a structure that prevents down from shifting and maintains fabric elasticity

A manufacturing process and anti-down technology, which is applied in the field of fabrics and fabrics, can solve the problems that down products are not suitable for close-fitting wear, limit the tension and elasticity of elastic fabrics, and limit the elasticity of elastic fabrics, so as to improve the anti-drilling performance, reduce weight, and apply strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

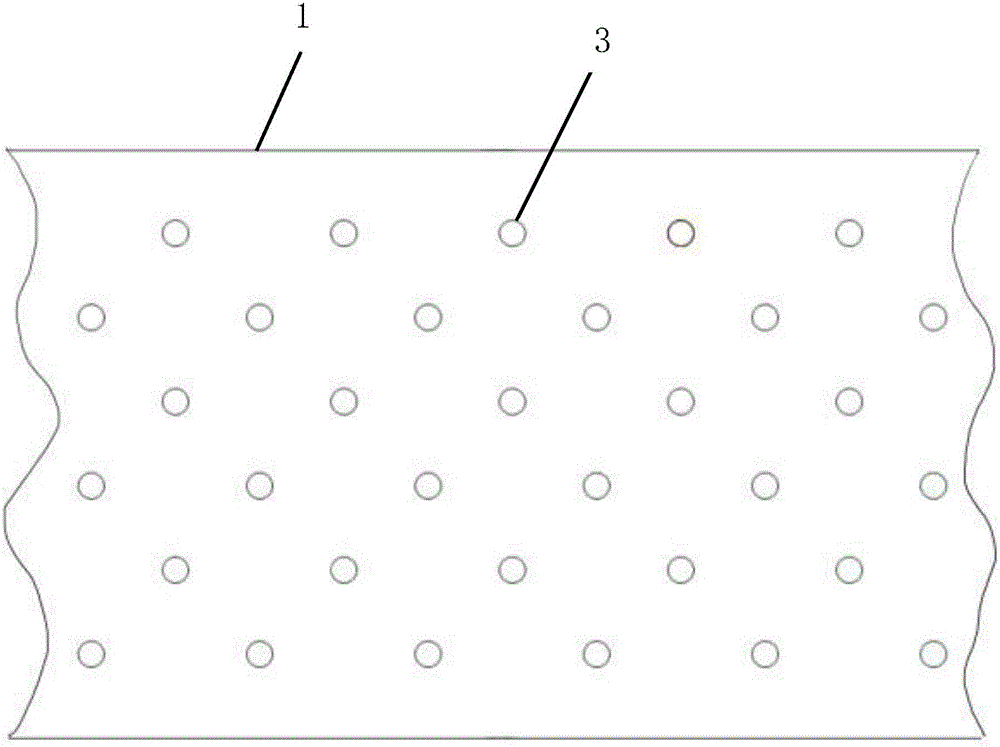

[0048] Such as figure 1 and figure 2 As shown, a structure that prevents down from shifting and maintains fabric elasticity, includes two layers of fabric layers 1 and down 2, and down 2 is filled between the two layers of fabric layers 1, and also includes a plurality of connection points 3, the connection points 3 is used for positioning the down 2, so that the down 2 is distributed in a net shape.

[0049] In this embodiment, the two layers of fabric layers 1 are warp-knitted or weft-knitted fabrics, woven fabrics with elastic or spandex, and elastic crepe fabrics; the down 2 can be down fillers such as duck down and goose down, cotton, pp Cotton, seven-hole cotton, nine-hole cotton, space cotton and other fiber fillings, or other bulk fillings such as mulberry silk; the connection point 3 connects the two fabric layers 1 together, and multiple connection points 3 form a connection point array. The connection point 3 can be circular, triangular or other patterns, and can...

Embodiment 2

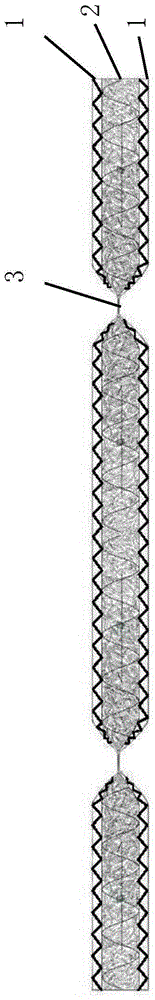

[0059] Such as figure 1 and image 3 As shown, a structure that prevents down from shifting and maintains fabric elasticity, includes two layers of fabric layers 1 and down 2, and down 2 is filled between the two layers of fabric layers 1, and also includes a plurality of connection points 3, the connection points 3 is used for positioning the down 2, so that the down 2 is distributed in a net shape. The two layers of fabric layers 1 are all made of stretching and elastic fabrics, and the down 2 is wrapped with an elastic breathable film 4. There is a gap between the elastic breathable film 4 and the two layers of fabric layers 1, and the connection point 3 is arranged on the inner surface of the elastic breathable film 4. Thus, the inner surfaces of the elastic air-permeable film 4 are connected.

[0060] In this embodiment, the two layers of fabric layers 1 are warp-knitted or weft-knitted fabrics, woven fabrics with elastic or spandex, and elastic crepe fabrics; the down ...

Embodiment 3

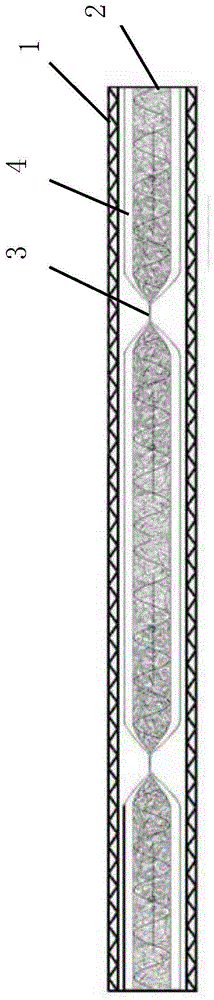

[0071] Such as figure 1 and Figure 4 As shown, a structure that prevents down from shifting and maintains fabric elasticity, includes two layers of fabric layers 1 and down 2, and down 2 is filled between the two layers of fabric layers 1, and also includes a plurality of connection points 3, the connection points 3 is used for positioning the down 2, so that the down 2 is distributed in a net shape.

[0072] The preferred mode of the present invention is that the two layers of fabric layers 1 all adopt stretching and elastic fabrics, and the down 2 is wrapped with an elastic air-permeable film 4, and there is a gap between the elastic air-permeable film 4 and the two layers of fabric layers 1, and the connecting point 3 connects the two layers. The fabric layers 1 are connected together, and the elastic breathable film 4 is compressed between the two fabric layers 1 .

[0073] In this embodiment, the two layers of fabric layers 1 are warp-knitted or weft-knitted fabrics, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com