Positioning and clamping device for inner hole grinding

A positioning clamping and grinding technology, which is applied in the direction of grinding the workpiece support, etc., can solve the problems of complex structure of the positioning clamping device, affecting inner hole grinding, etc., and achieves the effects of convenient loading and unloading, simplified structure, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

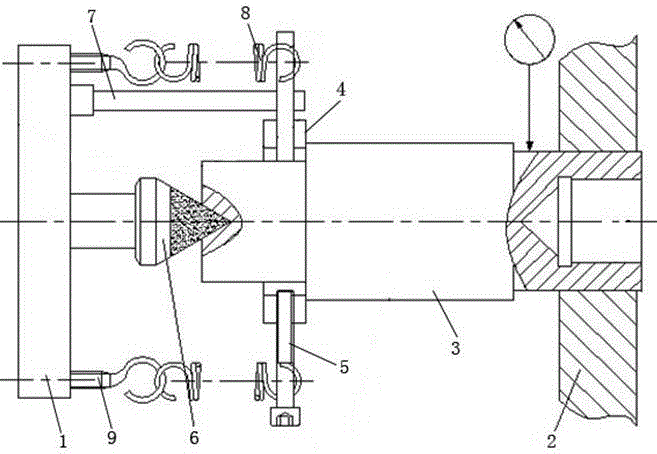

[0011] Embodiment 1 of the inner hole grinding positioning and clamping device of the present invention: as figure 1 As shown, it includes the fixed seat 1. The fixed seat 1 rotates synchronously with the spindle of the grinding machine. The spindle tip 6 extends to the right perpendicular to the fixed seat 1 and passes through the center of the fixed seat 1 to rotate and assemble with the fixed seat 1. The spindle tip 6 is fixed. And as a positioning reference, the fixed seat 1 is provided with two or more hooks 9 around the spindle top 6. The hooks 9 are screwed on the fixed seat by threads and can be adjusted in the left and right directions. The internal hole grinding positioning clamping device It also includes a clamping structure for clamping the workpiece 3. The clamping structure includes two push rods 5 that radially press against the outer peripheral surface of the workpiece 3 to clamp the workpiece. In this embodiment, the clamping structure includes a snap ring 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com