Universal loading device for gold wire bonding

A loading device and gold wire bonding technology, which is applied in the direction of auxiliary devices, metal processing equipment, auxiliary welding equipment, etc., can solve the problems of occupying the use time of the bonding table, achieve improved bonding efficiency, convenient and fast clamping, and save to wait for the effect of the warm-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] How the present invention is realized is further described below in conjunction with the accompanying drawings.

[0059] Such as figure 1 As shown, it is a common chip, and the chip base 1-1 and the chip 1-2 have been mounted as one;

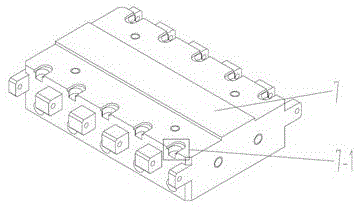

[0060] The current way of fixing and operating the gold wire bonding loading plate, such as figure 2 As shown, it includes: a pressing block 5 , a loading tray 6 , and a heating chassis 7 of a bonding station. Operation method: press the pressing block 5, clamp a single chip in the fixing groove of the device loading tray 6, loosen the pressing block 5, and fix the chip. Wait for the chip to preheat, and after preheating, the rivet 4 performs gold wire bonding to complete the bonding. Press the compression block 5, take out the chip and put it into the turntable. Repeating the above steps, one by one for clamping, preheating, bonding, and clamping operations, is inefficient.

[0061] The specific fixation and operation mode of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com