A flotation process to effectively reduce the pollution of high ash and fine mud in clean coal

A clean coal and fine mud technology, applied in flotation, solid separation, etc., can solve the problems of high ash content, difficult separation, fine particle size, etc., and achieve the effect of reasonable structure, reasonable recovery method and pollution avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

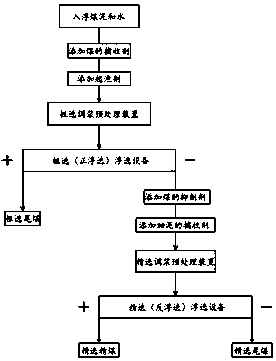

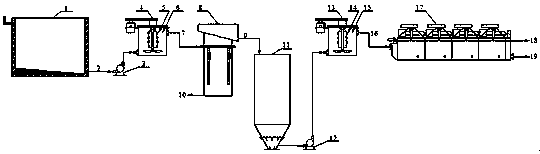

Method used

Image

Examples

Embodiment 1

[0041] Gas coal with a particle size of less than 0.5 mm and an ash content of 24.49% is used as flotation feed. In the flotation feed, the particle size is less than 0.045mm, the content is 62.88%, and the ash content is 33.08%. The actual production requires that the ash content of the flotation clean coal of this coal sample is less than 9.00%.

[0042] When adopting conventional primary flotation, kerosene is used as collector, and 2-octanol is used as foaming agent. Test procedure: The coal sample is prepared into 1.5 L of 60 g / L slurry, and poured into a single-tank hanging tank type mechanical agitation flotation machine with a volume of 1.5 L, and the spindle speed of the flotation machine is 1900 rad / min. The flotation pulp was pre-stirred for 2 minutes, then 1200 g / t of kerosene was added to the pulp and stirred for 2 minutes, then 300 g / t of secondary octanol was added and stirred for 0.5 minutes, and the air intake valve was opened for timing scraping and foaming ...

Embodiment 2

[0046] Coking coal with a particle size of less than 0.5 mm and an ash content of 37.71% was used as flotation feed. In the flotation feed, the particle size is less than 0.045mm, the content is 65.07%, and the ash content is 48.45%. The actual production requires that the ash content of the flotation clean coal of this coal sample is less than 11.00%.

[0047] When adopting conventional primary flotation, kerosene is used as collector, and 2-octanol is used as foaming agent. Test procedure: The coal sample is prepared into 1.5 L of 60 g / L slurry, and poured into a single-tank hanging tank type mechanical agitation flotation machine with a volume of 1.5 L, and the spindle speed of the flotation machine is 1900 rad / min. The flotation slurry was pre-stirred for 2 minutes, then 1000 g / t of kerosene was added to the slurry and stirred for 2 minutes, then 500 g / t of secondary octanol was added and stirred for 0.5 minutes, and the air intake valve was opened for 2.5 minutes of timi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com