Sealed reaction kettle and adjustment method thereof

A technology of sealing reaction kettle and adjustment method, applied in chemical/physical/physical-chemical stationary reactors, pressure vessels/vacuum vessels, pressure vessels used in chemical processes, etc., can solve problems such as inability to adjust and achieve stable sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

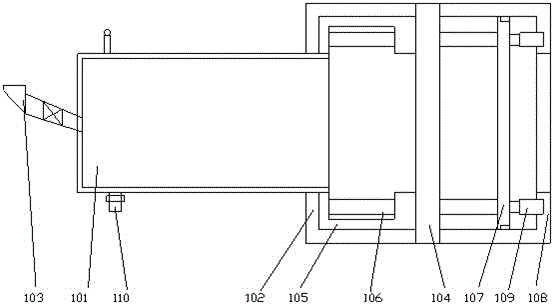

[0019] Such as figure 1 As shown, a sealed reaction kettle includes a front-end kettle body 101 and a rear-end kettle body 102 connected to the front-end kettle body 101. The end of the front-end kettle body 101 far away from the rear-end kettle body 102 is connected with the feed through a star valve. Port 103 is connected;

[0020] The rear-end kettle body 102 is set on the outer wall of the front-end kettle body 101, and an annular protrusion 104 is arranged on the inner wall of the middle part of the rear-end kettle body 102, and the annular protrusion 104 is arranged along the The inner wall of the rear kettle body 102 is arranged circumferentially, the axis of the annular protrusion 104 coincides with the axis of the rear kettle body 102, and the annular protrusion 104 is close to the front kettle body 101 One side is provided with a sealing ring 105, one end of the sealing ring 105 is sleeved on the outer wall of the front end kettle body 101, and the other end is pres...

Embodiment 2

[0027] A method for adjusting a sealed reaction kettle. A blind hole is provided on the side of the pressure plate 107 away from the front end of the kettle body 101, and a screw thread corresponding to the position of the blind hole is provided on the limiting plate 108. Bolts are provided in the threaded through holes, and the front ends of the bolts are pressed against the blind holes, and the bolts are turned to push the pressure plate 107 to adjust the pressure plate 107 along the axial direction of the rear kettle body 101 The distance relative to the front end kettle body 101.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com