Corn stubble harvester

A harvester, stubble technology, applied in the field of agricultural machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

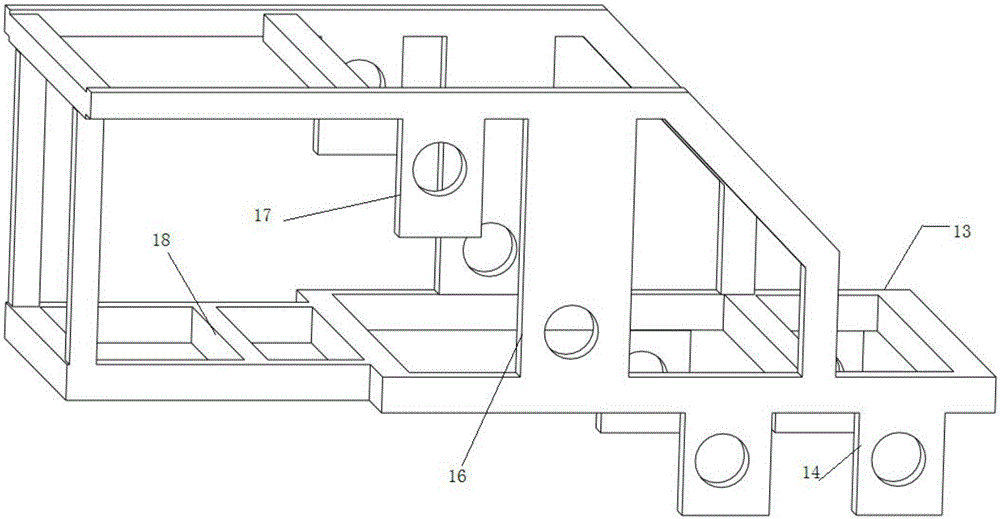

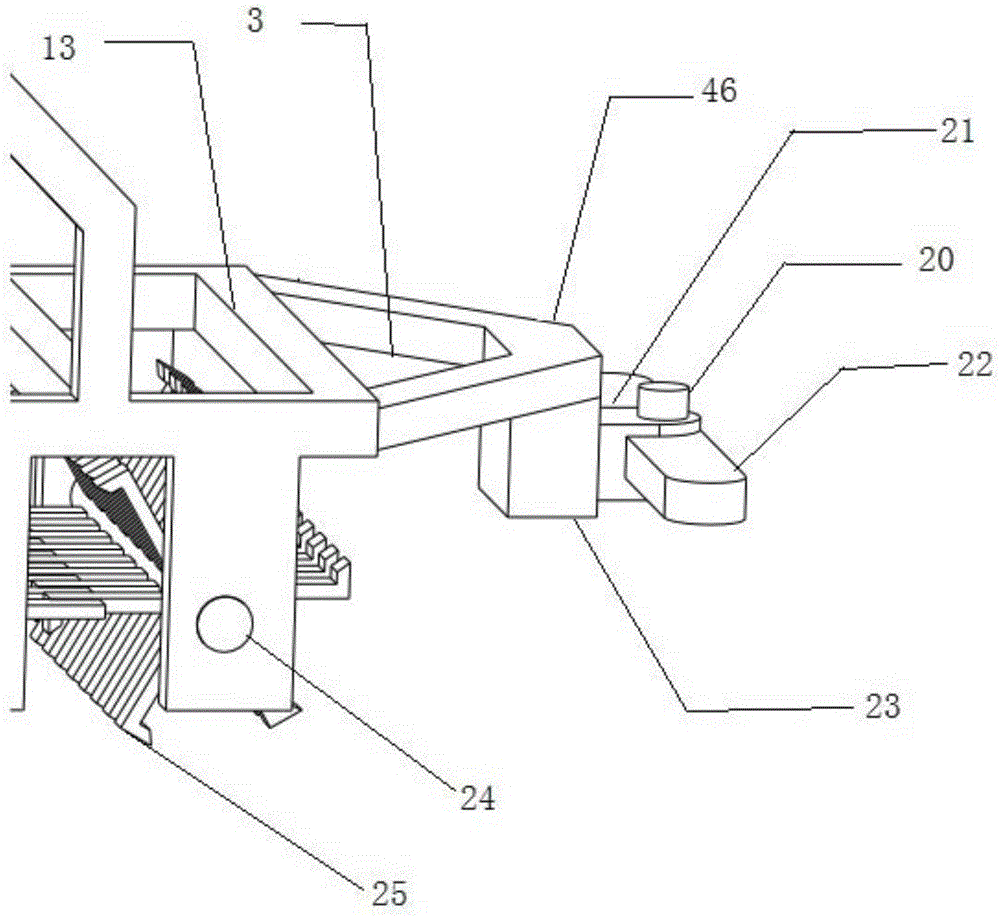

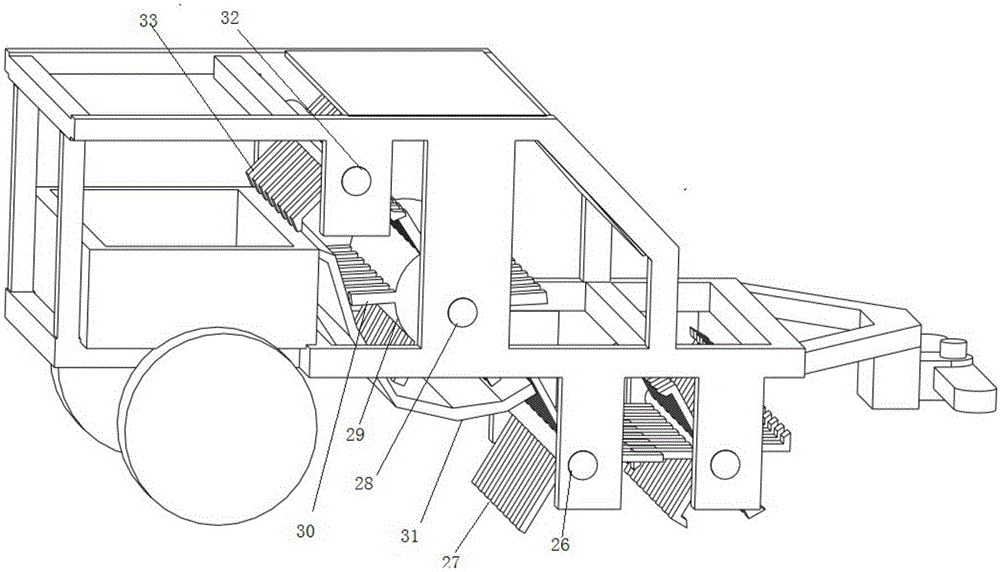

[0022] Specific implementation mode one: combine figure 1As shown, it includes a vehicle frame 1, a receiving box 2, a bogie 3, a reducer 4, a stubble picker 5, a first-level stubble picker 6, a roller grid plate soil removal mechanism 7, a second-level stubble picker 8, and a second stubble picker. Level drive system 9, level drive system 10, wheels 11, wheel axles 12, U-shaped card group 19; front beam 13 is provided at the front of vehicle frame 1; A shaft seat 14 is provided at the side of vehicle frame 1; A shaft seat 14 A B-axis seat 15 is provided at the back; a C-axis seat 16 is provided in the middle of the side of the vehicle frame 1; a D-axis seat 17 is provided on the side of the tail of the vehicle frame 11; an axle beam 18 is provided at the rear of the vehicle frame 1; the stubble picker 5 is connected to the A-axis On the seat 14; the first-level stubble puller 6 is connected on the B-axis seat 15; the roller grid plate soil removal mechanism 7 is connected on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com