Materials and methods

A technology of substrate and polysaccharide, applied in chemical instruments and methods, separation methods, starch coatings, etc., can solve problems such as heat transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

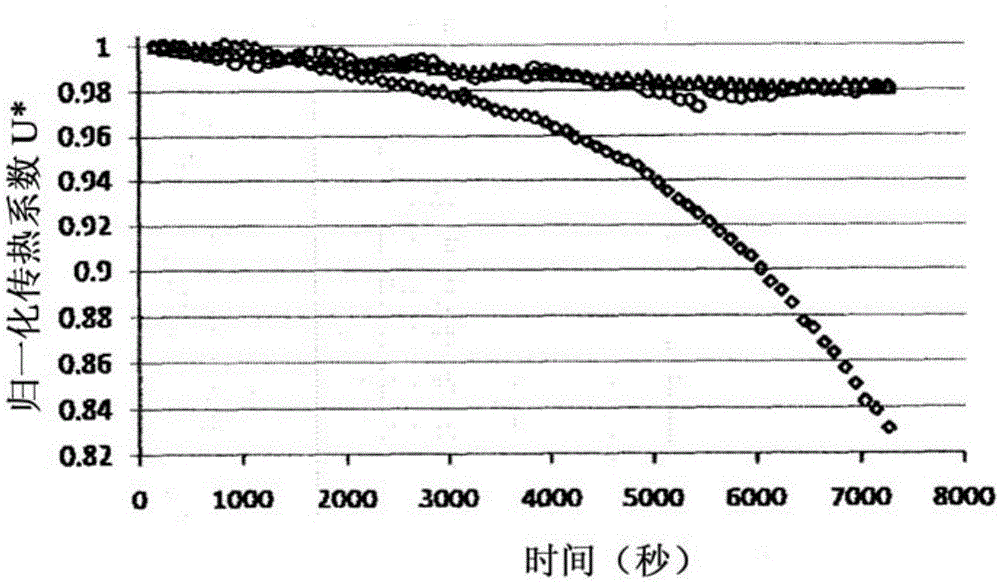

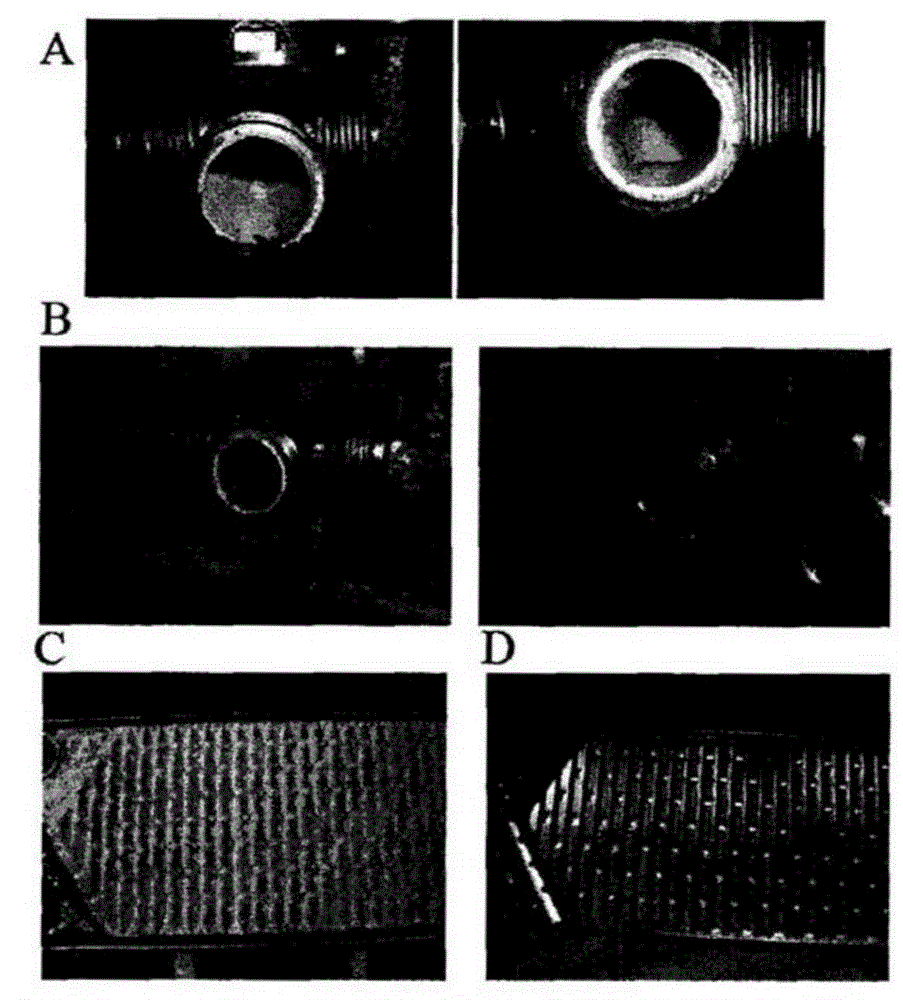

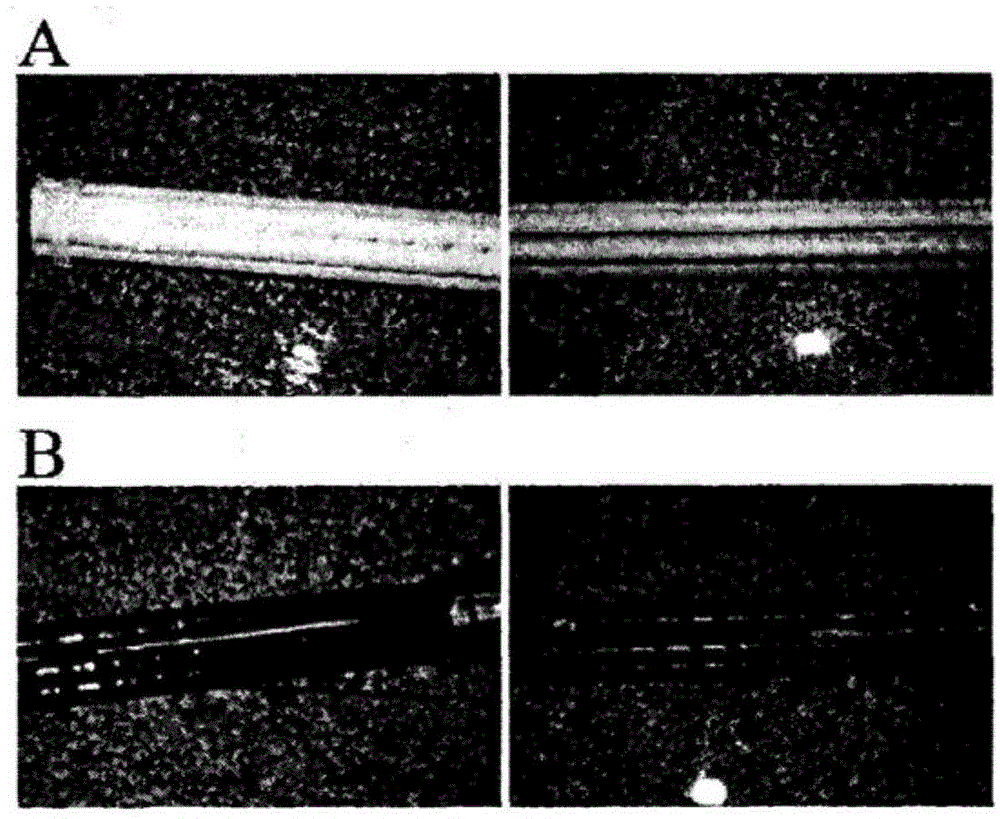

[0058] Example 1 - Analysis of milk scale using a plate heat exchanger as a substrate, and analysis of cooling water fouling using a UHT heat exchanger as a substrate

[0059] Materials and methods

[0060] Substrate Coating

[0061] The polysaccharide (in this case, 35% dextrin starch was mixed with 65% OSA starch, and the final concentration of the mixture in water was 8.5% (w / w), its pH value was about 3.5) was dissolved in 55 ℃ water and heat it to 85 ℃. Pump the solution into the heat exchanger, circulate for 4 hours and maintain the temperature at 95°C, with a flow rate of 17 L / min in the plate heat exchanger and 35 L / min to 40 L / min in the UHT heat exchanger minute. The polysaccharide solution was drained after 4 hours. Protein solution (80% casein (with calcium) mixed with 20% whey protein to a final concentration of 12% (w / w) in water, pH 6.7) at a temperature below 50°C Dissolve and pump into the heat exchanger at the same flow rate as the polysaccharide solutio...

Embodiment 2

[0115] Example 2 - Using the dairy processing production line as a base material to analyze milk scale

[0116] Materials and methods

[0117] Substrate Coating

[0118] The polysaccharide (in this case, 35% dextrin starch was mixed with 65% OSA starch, and the final concentration of the mixture in water was 9% (w / w), its pH value was about 3.5) was dissolved in 85 ℃ water. The solution was pumped into the heat exchanger, circulated for 5 hours and the temperature was maintained at 95 °C, its flow rate in the Amotec-THE heat exchanger was 10 L / min, and the stirring speed in the pot heat exchanger (potheat exchanger) 80r / min. The polysaccharide solution was drained after 5 hours. Protein solution (80% casein (with calcium) mixed with 20% whey protein to a final concentration of 12% (w / w) in water, pH 6.7) at a temperature below 50°C Dissolve and pump into the heat exchanger at the same flow rate and agitation rate as the polysaccharide solution. The protein solution was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com