Full-automatic surface-mounting machine electrically connected with controller

An electrical connection, fully automatic technology, applied in the direction of assembling printed circuits, electrical components, printed circuits, etc. with electrical components, can solve the problems of low production efficiency, low product qualification rate, not tight enough fit, etc., to improve the placement Efficiency, streamlining the structure of the whole machine, and ensuring the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

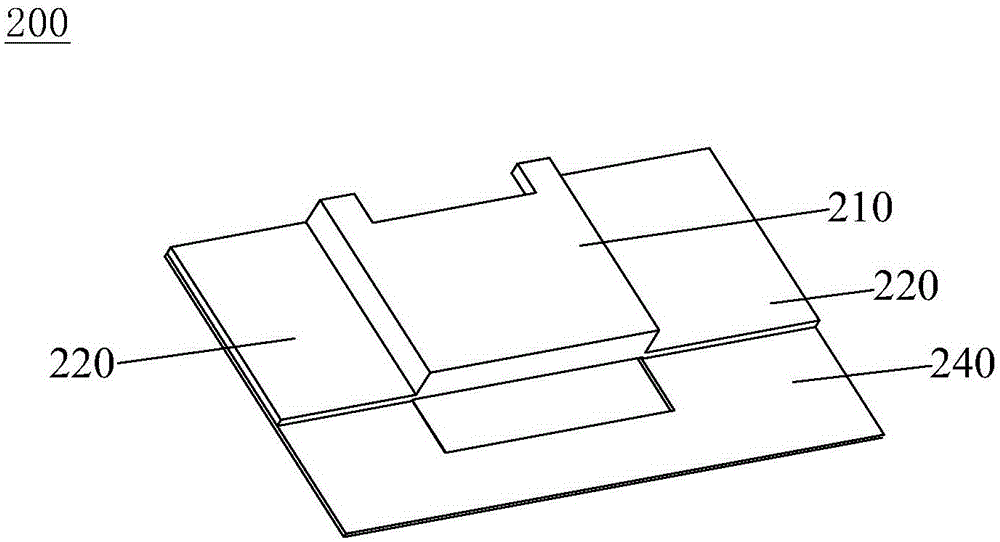

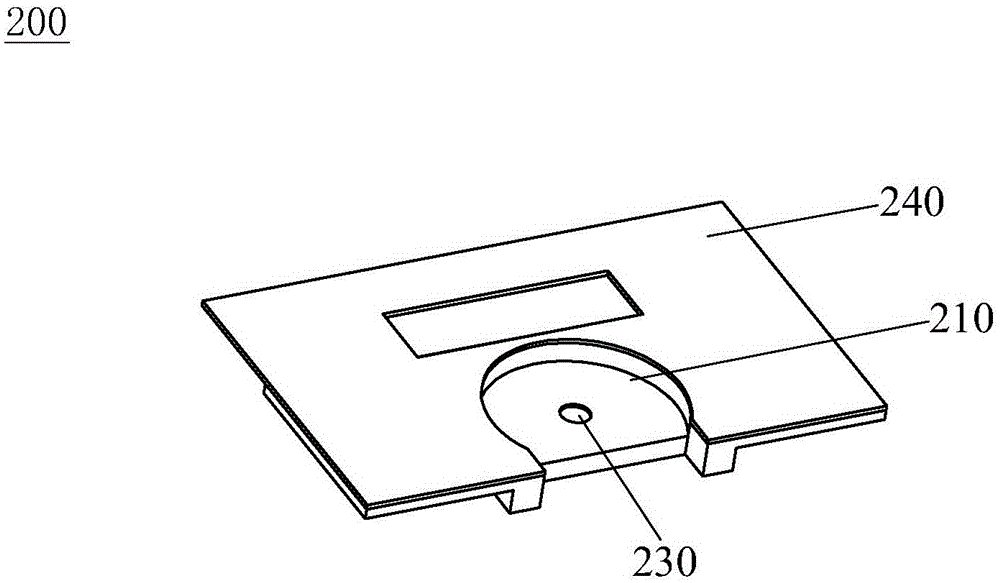

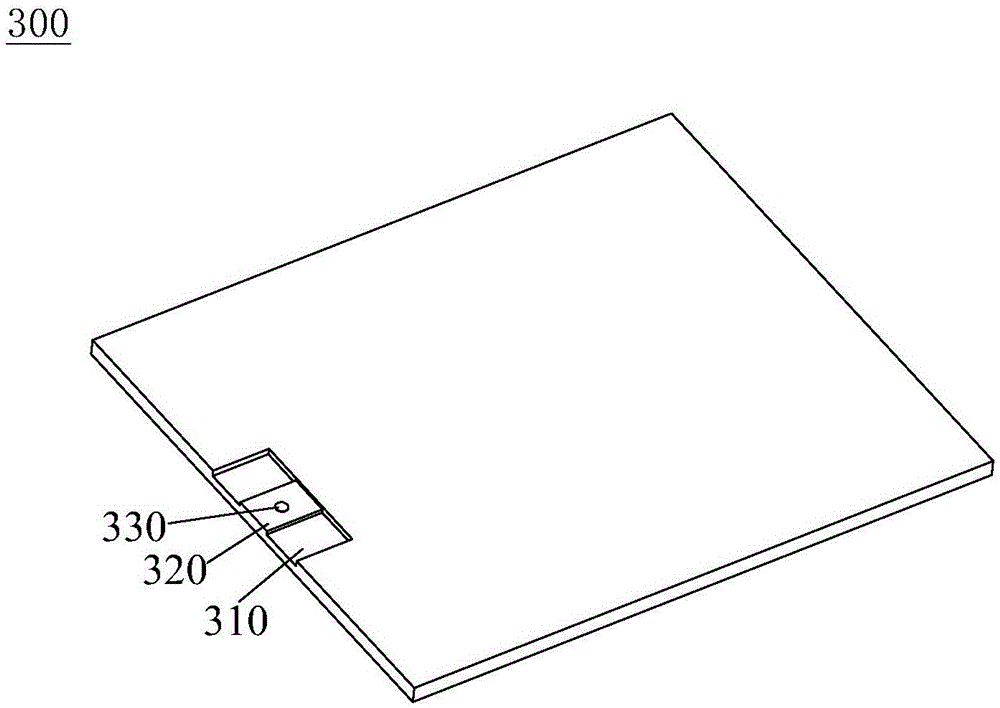

[0034] see Figure 1 to Figure 23 , the present invention discloses a fully automatic placement machine 100 electrically connected to a controller (not shown in the figure), and is used to attach a special-shaped component 200 to a substrate 300. Due to the problem of not being able to fit tightly due to processing errors, a connecting piece 400 is provided between the special-shaped component 200 and the substrate 300 to make the two closely fit, and the adjustment and compensation of the connecting piece 400 can make the special-shaped component 200 closely adhere to the substrate 300 . Specifically, in this embodiment, the bottom surface of the special-shaped component 200 is a mounting surface that is bonded to the substrate 300, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com