Method and system for testing distortion rate of camera

A test method and test system technology, applied in the direction of image communication, television, electrical components, etc., can solve the problems of not being able to realize online continuous multiple tests, difficulty in popularization, and high cost, and achieve shortened correction time, low cost, and saving the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

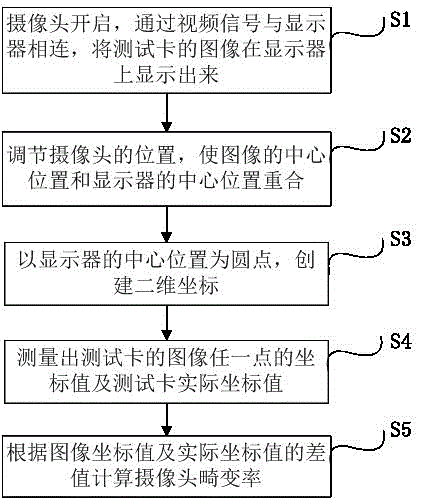

[0017] like figure 1 As shown, the camera distortion rate testing method of the present invention comprises the following steps:

[0018] S1: The camera is turned on, connected to the monitor through the video signal, and the image of the test card is displayed on the monitor;

[0019] S2: adjust the position of the camera so that the center position of the image coincides with the center position of the display;

[0020] S3: Create two-dimensional coordinates with the center of the display as the dot;

[0021] S4: Measure the coordinate value of any point on the image of the test card and the actual coordinate value of the test card;

[0022] S5: Calculate the camera distortion rate according to the difference between the image coordinate value and the actual coordinate value.

[0023] In the present embodiment, in step S1, the test card ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com