Double cage rotor lamination, double cage rotor and motor

A technology of rotor punching and rotor, which is applied in the field of motors with the double-cage rotor, can solve problems such as lifting, single structure, and unfavorable overall performance of the motor, and achieve the effects of improving the overall performance, enhancing the overall performance, and achieving a significant skin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the present invention clearer, the following describes the double-cage rotor punching piece, double-cage rotor and motor of the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

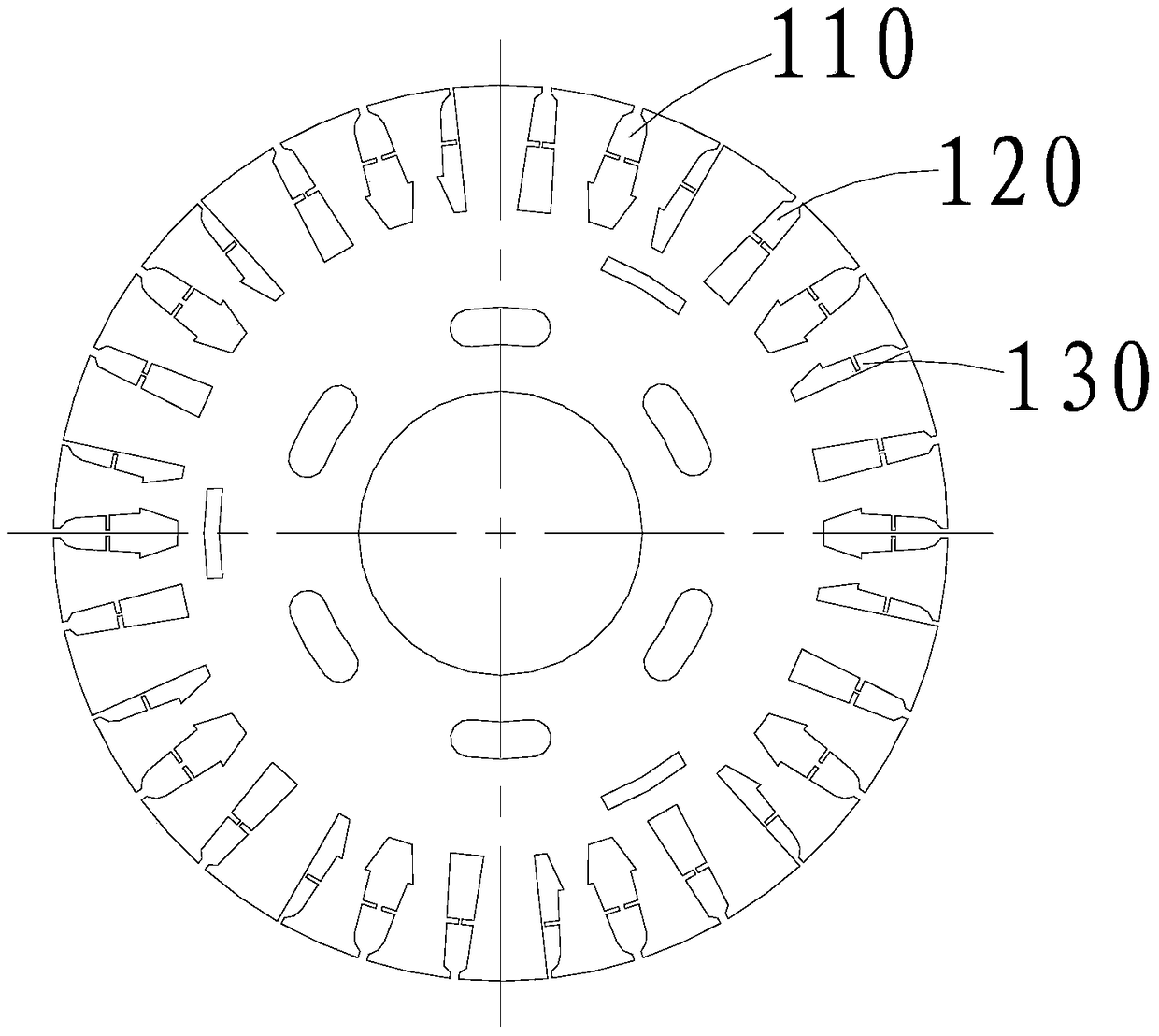

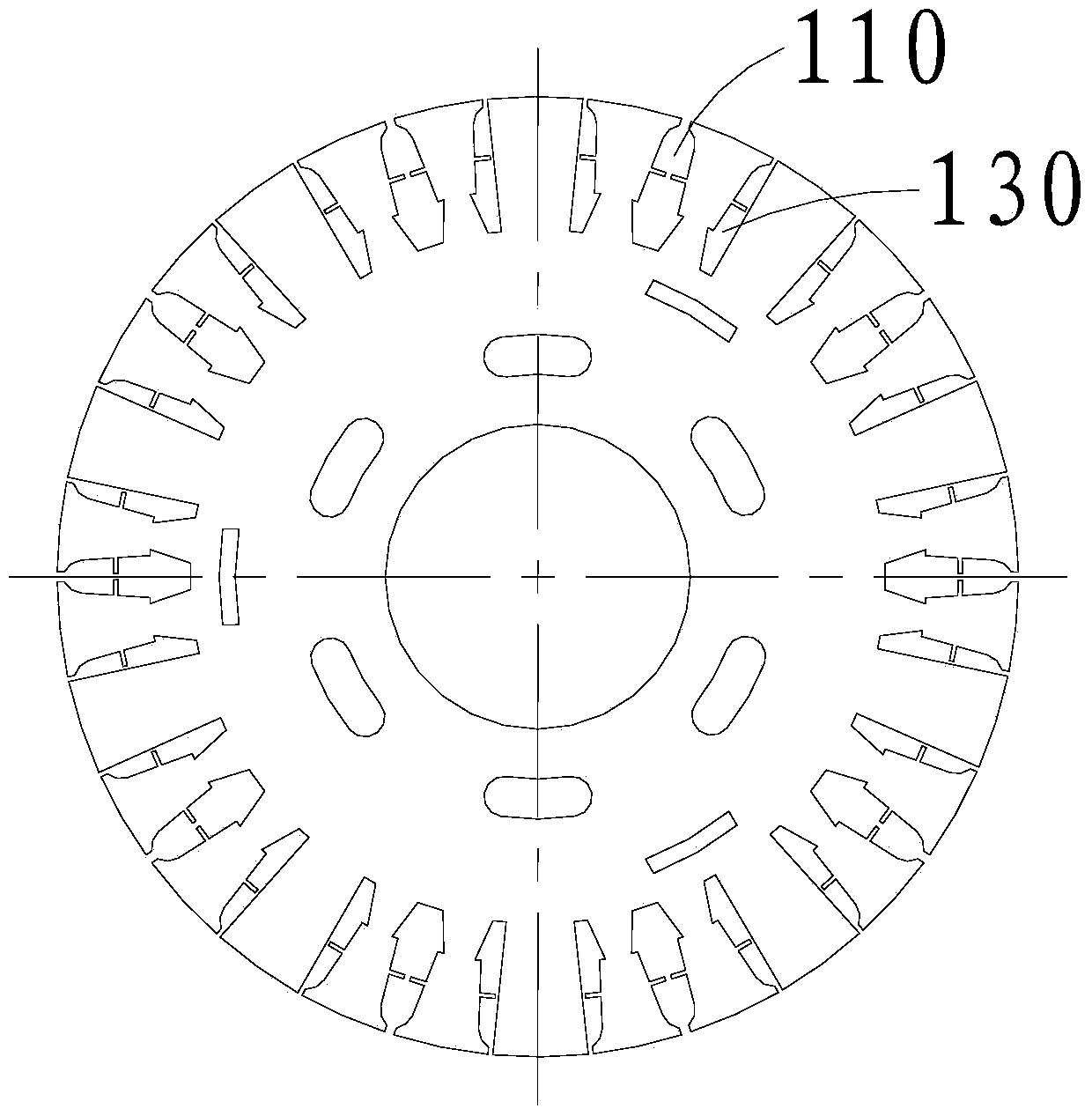

[0032] The present invention provides a double-cage rotor punch, such as Figure 1 to Figure 4 As shown, the double-cage rotor punching piece of the present invention has a circular structure, and the double-cage rotor punching piece of the circular structure is provided with a plurality of rotor slots along the circumferential direction. Wherein, the plurality of rotor slots are a combination of any two or three kinds of slot structures among the double-cage convex-shaped slot 110 , the double-cage trapezoidal slot 120 and the doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com