Aluminum profile passivation process conductivity detection control device

A technology of detection control and conductivity, which is applied in the field of conductivity detection and control devices in the passivation process of aluminum profiles, which can solve problems such as difficult maintenance, strong solution corrosion, and fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with specific examples.

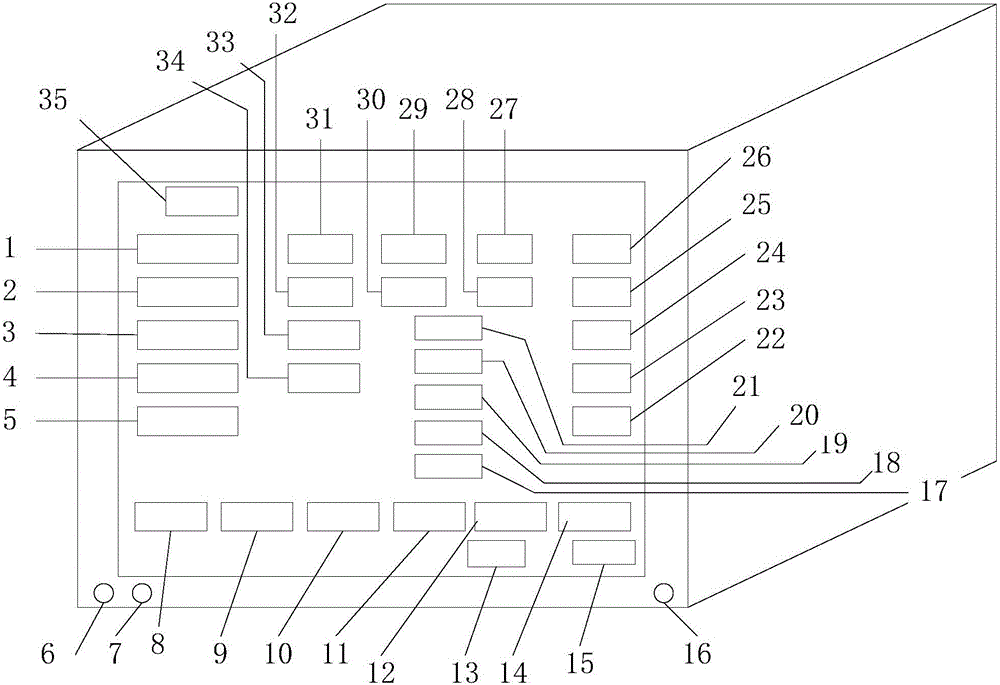

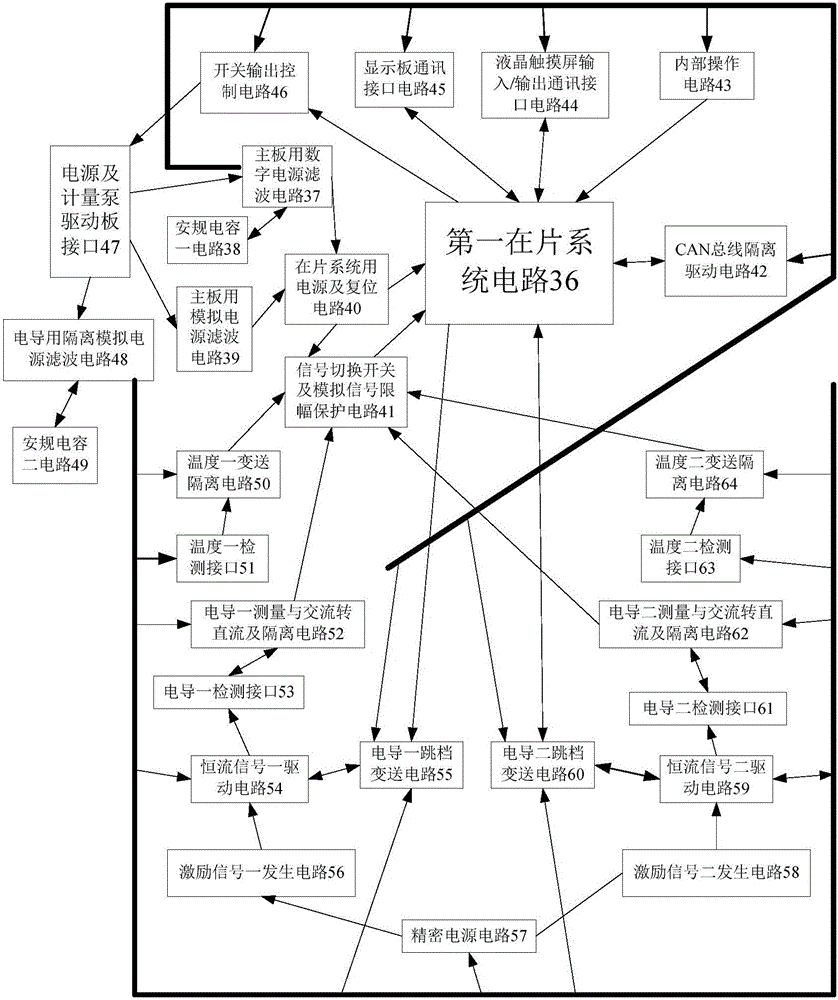

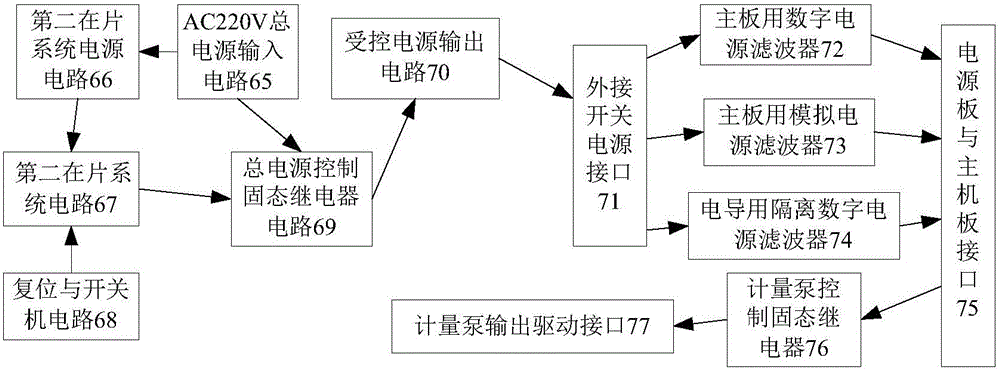

[0043] Such as figure 1 As shown, the aluminum profile passivation process conductivity detection and control device described in this embodiment adopts a casing with a size of 290×250×450 mm, and a panel, a liquid crystal touch screen (standard industrial control), and a main board are installed in the casing. , power supply and metering pump drive board, four switching power supply modules, connecting cables, AC power filter, power input and output sockets, two-way conductivity electrode cable connectors, two-way temperature cable connectors, four-way metering pump drive output sockets, grounding terminal , CAN bus connection socket, wherein, the power supply and the metering pump drive board are separately equipped with a shielding box, and the shielding white iron plate is separately installed on the main board, and the liquid crystal touch screen is installed on the panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com