Test method for motor under high-temperature and high-pressure environment

A high temperature and high pressure, test method technology, applied in the direction of motor generator testing, etc., can solve the problem of not meeting the motor test and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Specific implementation mode one: combine figure 1 Shown, illustrate the technical scheme of this embodiment, its method step is:

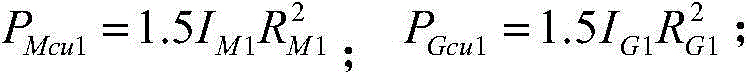

[0028] Step 1: Select a motor with the same specifications as the tested motor 1, or a motor with the same synchronous speed as the tested motor 1 but with a power greater than the tested motor 1 as the accompanying motor 2; the output shaft of the tested motor 1 Connect with the output shaft of the accompanying motor 2 through the coupling 3, then put it into the high-pressure high-temperature sealed barrel 4 and fix it, wind the heating cable outside the high-pressure high-temperature sealed barrel 4 or set the pressure resistance inside the high-pressure high-temperature sealed barrel 4 The high-power electric heater is wrapped with insulating and refractory insulation material on the outside, the inside of the high-pressure high-temperature sealed barrel 4 is filled with experimental oil, and the test temperature in the high-pressure hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com