Heat Exchanger

A heat exchanger and cooling fin technology, applied in the field of heat exchanger equipment, can solve the problems of easy corrosion, corrosion, and poor heat exchange effect of the heat exchanger, and achieve enhanced installation stability, firm insertion, and not easy to fall off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

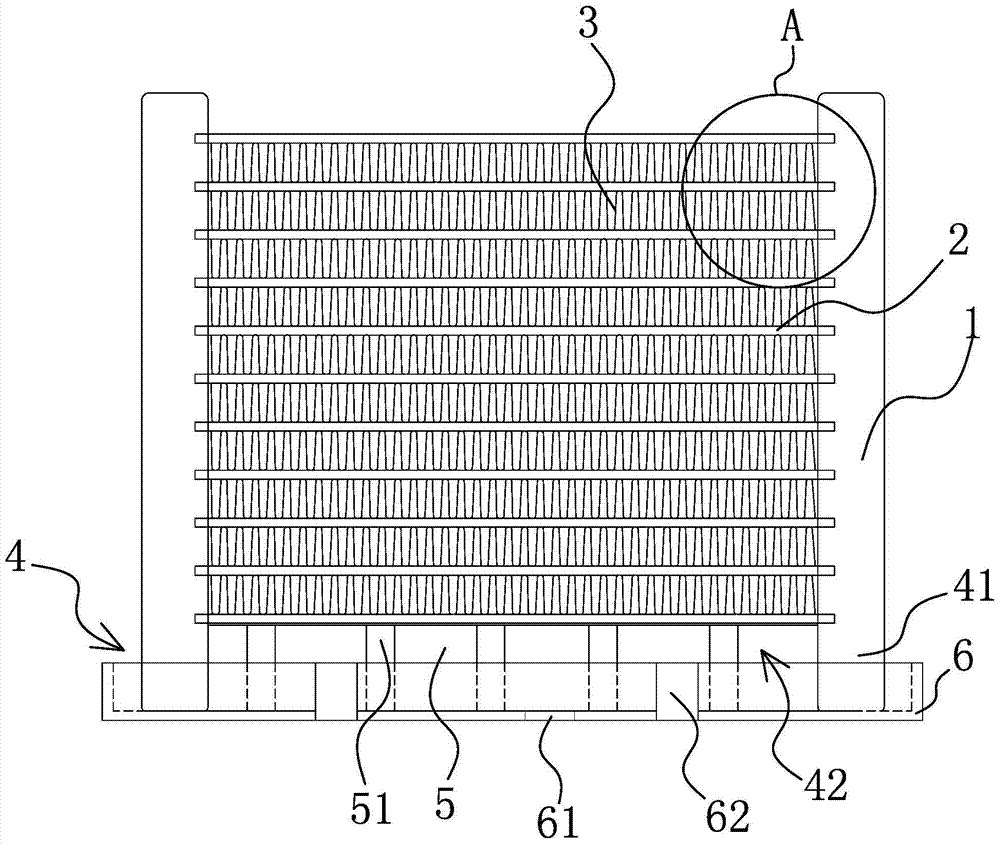

[0030] Such as Figure 1-2As shown, the heat exchanger includes two headers 1 parallel to each other and vertically arranged, and a number of flat tubes 2 parallel to each other and arranged horizontally are arranged between the headers 1, and each flat tube 2 is arranged along the The tubes 1 are arranged at intervals in the axial direction, and the two ends of the flat tubes 2 are respectively connected with the collecting tubes 1. There are also a number of cooling fins 3 in contact with the flat tubes 2 between the collecting tubes 1, and the flat tubes 2 are arranged horizontally and / or Or inclined to the horizontal plane, the lower end of the header 1 is provided with an overhead structure 4 that can prevent the flat tube 2 and cooling fins 3 from contacting with the accumulated liquid during work. Using this structure can make the bottom of the heat exchanger overhead to prevent The flat tube 2 is in contact with the radiating fin 3 and the effusion, which avoids the ru...

Embodiment 2

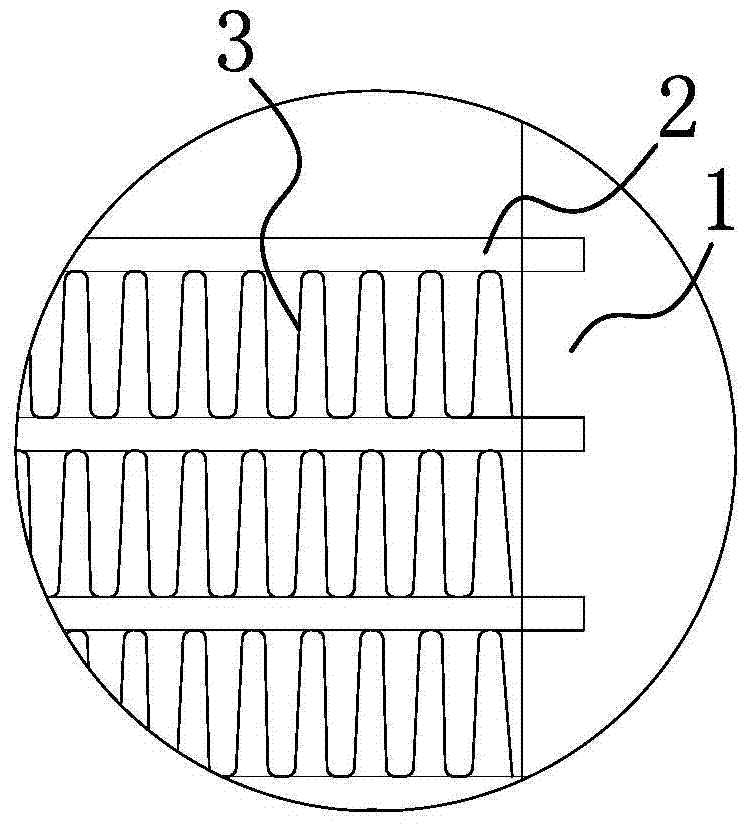

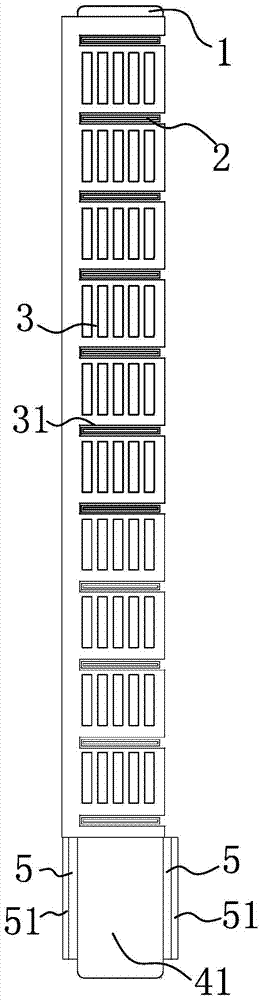

[0034] Such as image 3 As shown, the structure, principle and implementation steps of this embodiment are similar to those of Embodiment 1, the difference is that the heat dissipation fins 3 in this embodiment are made of metal sheets, and the heat dissipation fins 3 are vertically parallel to each other. Adjacently arranged and each cooling fin 3 crosses each flat tube 2 respectively, preferably, the flat tube 2 here is arranged transversely between two headers 1, and the cooling fin 3 is arranged vertically and intersects with the flat tube 2 Intersecting arrangement, wherein, the side of the cooling fins 3 here is provided with horizontal slots 31 corresponding to each flat tube 2 one by one, the flat tubes 2 are horizontally arranged and inserted in the horizontal slots 31, the depth of the horizontal slots 31 greater than the width of the flat tubes 2, that is, the flat tubes 2 here are arranged parallel to each other, and the cooling fins 3 are connected to each other t...

Embodiment 3

[0036] Such as Figure 4-10 As shown, the structure, principle and implementation steps of this embodiment are similar to those of Embodiment 1, the difference is that the heat dissipation fins 3 in this embodiment are made of metal sheets, and the heat dissipation fins 3 are vertically parallel to each other. Adjacently arranged and each cooling fin 3 crosses each flat tube 2 respectively, preferably, the flat tube 2 here is arranged transversely between two headers 1, and the cooling fin 3 is arranged vertically and intersects with the flat tube 2 Arranged crosswise, the sides of the cooling fins 3 are provided with inclined slots 32 corresponding to the flat tubes 2 one by one. The flat tubes 2 are arranged obliquely and inserted into the inclined slots 32. width, that is, the flat tube 2 here is set obliquely to the horizontal plane, so that the condensate can be discharged faster, and it is not easy to gather on the flat tube 2, and the cooling fins 3 are cross-connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com