Automatic oil filling device of oil rotary vane vacuum pump

A rotary vane vacuum pump, automatic refueling technology, applied to parts of pumping devices for elastic fluids, rotary piston pumps, pumps, etc., can solve problems such as large production impact, lower oil level, vacuum pump damage, etc., to achieve operation Convenience, impact reduction, and productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

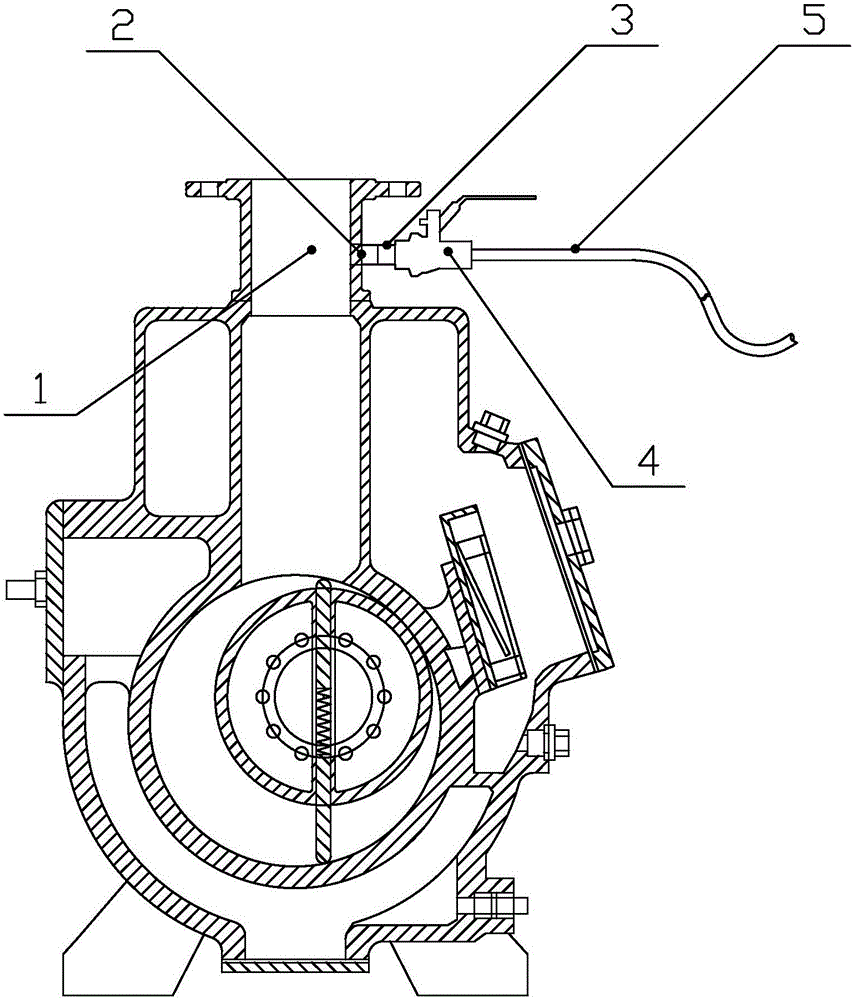

[0015] The automatic refueling device of the oil-type rotary vane vacuum pump of the present invention is mainly composed of an oil inlet 2, a metal pipe 3, a flow control valve 4, and an oil suction pipe 5 arranged on the outer wall below the vacuum suction port 1.

[0016] One end of the metal pipe 3 is connected to the oil inlet 2. Preferably, the connection mode between the oil inlet 2 and the metal pipe 3 is threaded connection, the oil inlet 2 is an internal thread, and the metal pipe 3 is a corresponding Matching external thread; the other end is connected to the flow control valve 4, which is a switch for controlling the flow rate of the vacuum pump oil flowing through; one end of the oil suction pipeline 5 is connected to the flow control valve 4, and the other end is a free The end extends into the vacuum pump oil drum, such as figure 1 shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com