Self-adaptive step-by-step speed regulation method for diesel engine

A step-by-step speed regulation, diesel engine technology, applied in mechanical equipment, engine control, machine/engine, etc., can solve problems such as inconvenience, complicated replacement work, trouble, etc., to prevent accidental human error, good control effect, speed Small error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

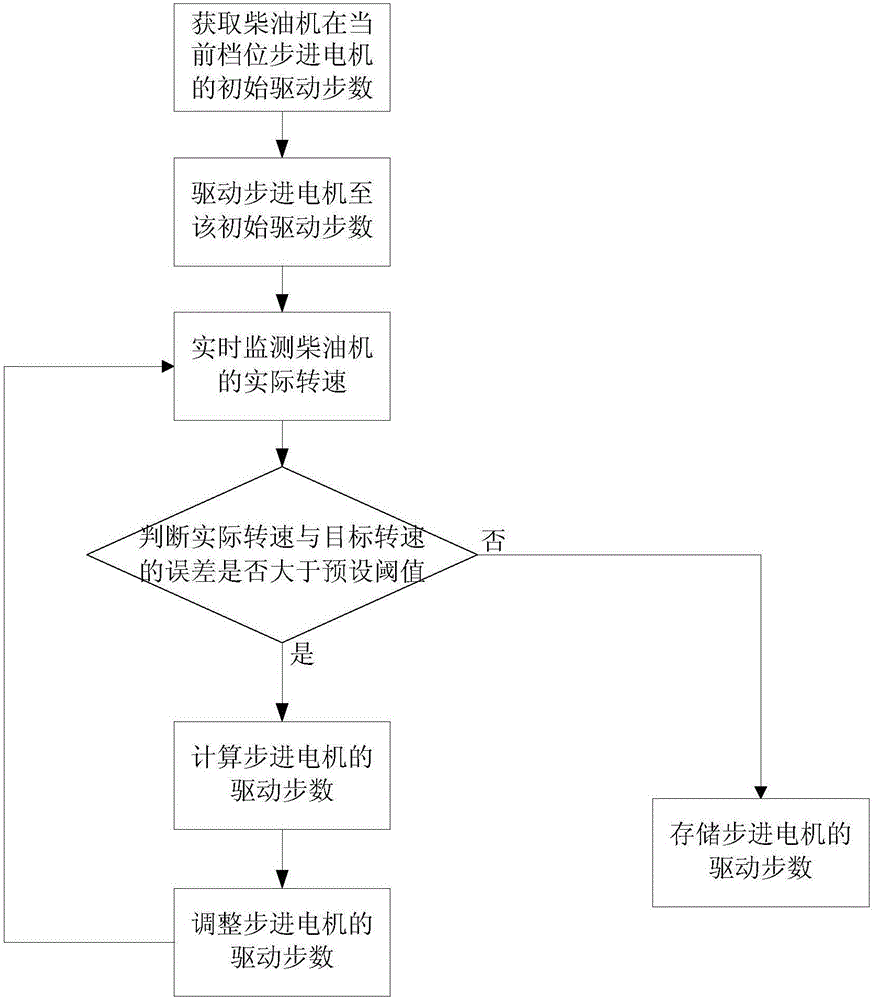

[0032] Such as figure 1 Shown, a kind of adaptive diesel engine step speed regulation method of the present invention, its specific implementation process is as follows:

[0033] In the present embodiment, suppose the maximum number of gears M of the diesel engine is 16 gears, the empirical theoretical estimation value of the initial driving steps of the stepper motor at this gear is 900 steps, after the diesel engine starts, when the gears change, The adaptive speed regulation process of the stepper motor is:

[0034] Adjust the gear position of the diesel engine controller to N gear, follow the steps below to obtain the initial driving steps of the stepper motor and drive the stepper motor:

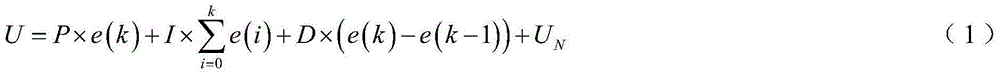

[0035] S1.1a. Read the value U stored in the stepping speed regula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com