A door structure with a bottom rolling barrier

A blocking strip and rolling technology, which is applied in the layout of wing leaves, door/window accessories, building structures, etc., can solve the problems of affecting aesthetics, damage to the door body, and affecting re-installation, etc., to achieve smooth front and back Beautiful appearance, less dust entering the room, and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

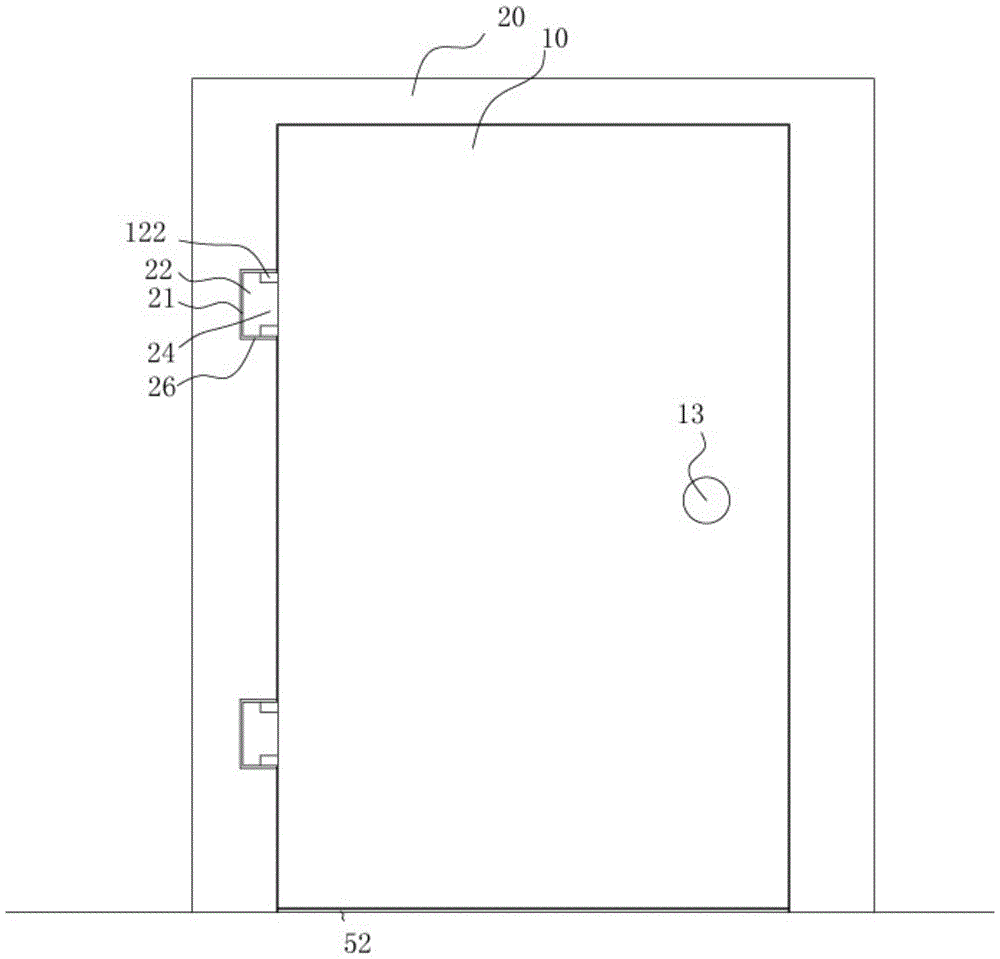

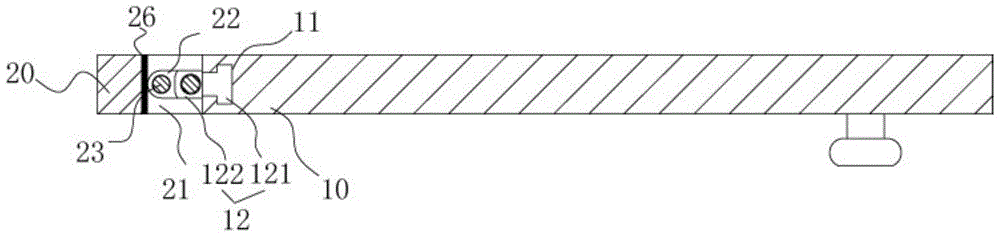

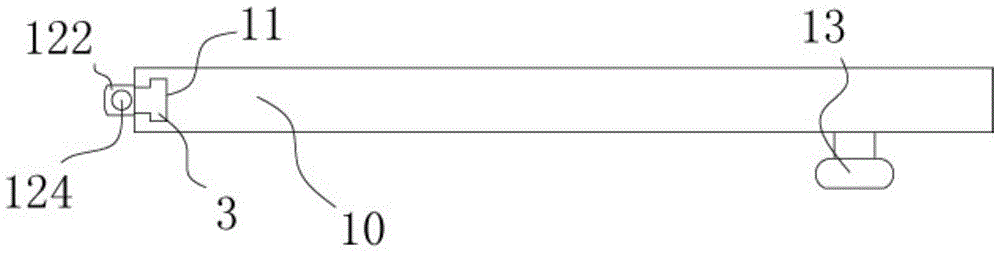

[0028] Example: see Figures 1 to 8 As shown, a door body structure with a bottom rolling barrier bar includes a door body 10 and a door frame 20, the door body 10 is located in the door frame 20, and the side wall of the door body 10 has a vertical convex groove 11. The convex-shaped parts 121 of at least two connecting blocks 12 are inserted into the convex-shaped grooves 11. The front part of the connecting block 12 has two hinge parts 122, and one inner side wall of the corresponding door frame 20 has a connecting groove 21 A hinge 22 is sleeved in the connection groove 21, and a hinge shaft 23 is inserted in the hinge 22. The two ends of the hinge shaft 23 are fixed on the upper and lower side walls of the connection groove 21. The middle part of the hinge 22 has Protruding part 24, the protruding part 24 is between the two hinge parts 122 of a connecting block 12, the protruding part 24 is connected with the hinge part 122 through the connecting shaft 25, and the handle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com