Preparation method for beet flavor for tobacco

A technology of sugar beets and spices, applied in the direction of essential oils/spices, tobacco, applications, etc., can solve the problems of maintaining the characteristic aroma components of spices, low cellulose reduction rate, and cost increase, etc., to achieve reduced cellulose content, less residue, Yield-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Get 500 grams of fresh beets, add 2.5L of clear water to wash twice, use a juicer to beat the cleaned beets, collect the slurry, and the slurry is beet juice; get 5g cellulase (this cellulase was produced in Hangzhou, China) Aroma Chemical Co., Ltd.), add 25mL of quality distilled water and stir to dissolve, and then filter with a 0.8 micron filter membrane to get the filtrate to obtain a cellulase solution; take 0.1g of the cellulase solution and add it to 1L of beet juice. 3. Carry out enzyme treatment reaction at 25°C for 5 hours to obtain an enzyme treatment solution; then adjust the pH value of the enzyme treatment solution to 8 at a stirring speed of 6000 rpm, carry out isoelectric point precipitation, and stir for 30 minutes. Stand still for 24 hours to obtain the enzyme-treated sedimentation liquid; coarsely filter the enzyme-treated sedimentation liquid with gauze to filter out large particles of impurities, and then filter the coarse filtrate again with a 0.8 m...

Embodiment 2

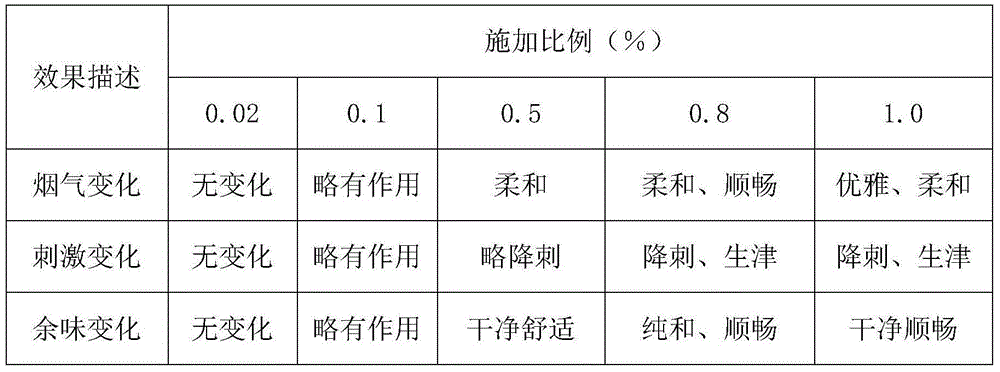

[0028] Carry out embodiment 1 repeatedly by the same steps as described, the difference is that the consumption ratio of used cellulase solution and beet juice is 1 gram of cellulase solution: 1 liter of beet juice; The pH value of enzyme treatment is 5, and the enzyme treatment temperature at 30°C, and the enzyme treatment time is 12 hours; when carrying out isoelectric point precipitation, the stirring speed is 7000 rpm, adjust the pH value of the enzyme treatment solution to 9, stir for 30 minutes, and stand for 12 hours; during the concentration process, concentrate The temperature is 60°C and the concentration pressure is 0.1 atmosphere. Concentrated to a relative density of beet spices of 1.157g / cm 3 . Compared with the pressed beet juice, the cellulose concentration of the tobacco beet flavor prepared by the method of the invention is reduced by 84.50%, and compared with the tobacco beet flavor without cellulase treatment and other treatment steps, the cellulose concen...

Embodiment 3

[0030] Carry out embodiment 1 repeatedly by the same steps as described, the difference is that the consumption ratio of used cellulase solution and beet juice is 5 grams of cellulase solution: 1 liter of beet juice; The pH value of enzyme treatment is 5, and the enzyme treatment temperature at 40°C, and the enzyme treatment time is 15 hours; when performing isoelectric point precipitation, the stirring speed is 7000 rpm, adjust the pH value of the enzyme treatment solution to 9, stir for 30 minutes, and stand for 14 hours; during the concentration process, concentrate The temperature is 60°C and the concentration pressure is 0.1 atmosphere. Concentrated to a relative density of beet flavor of 1.165g / cm 3 . Compared with the pressed beet juice, the cellulose concentration of the tobacco beet flavor prepared by the method of the invention is reduced by 86.50%, and compared with the tobacco beet flavor without cellulase treatment and other treatment steps, the cellulose concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com