Oppositely-rotating shaft-less rim-driven propeller

A technology of rim drive and propeller, which is applied in the direction of rotary propeller, ship propulsion, propulsion components, etc. It can solve the problems of difficult manufacturing, high manufacturing and maintenance costs, and motor size limitations, so as to avoid head-on resistance and winding , good lateral stability and high propulsion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the embodiments and drawings, but not limited to the following embodiments.

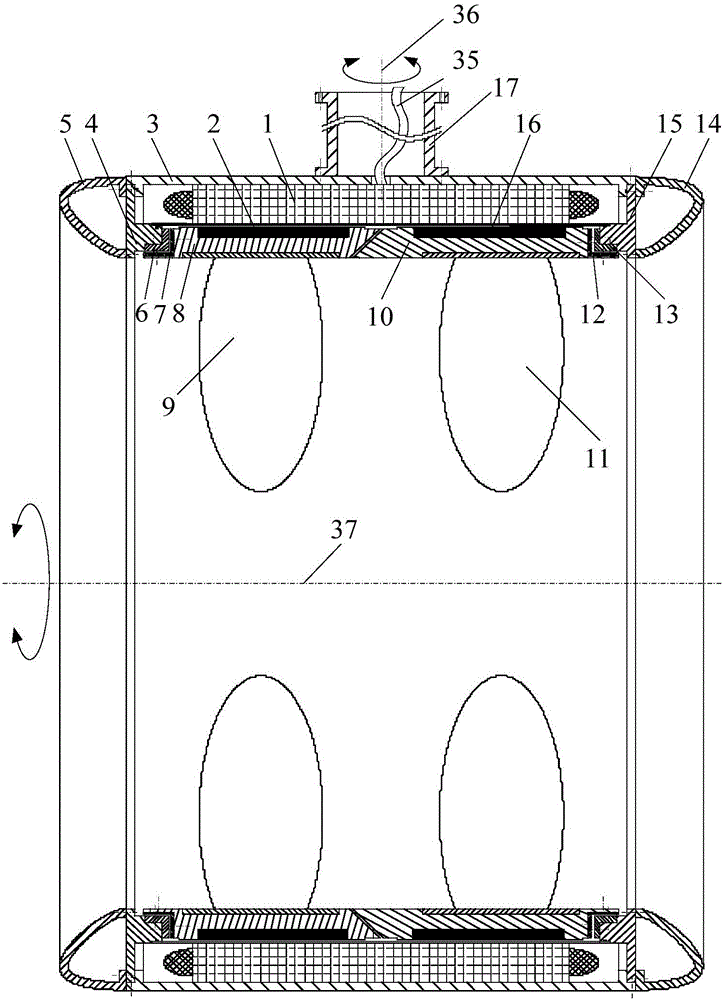

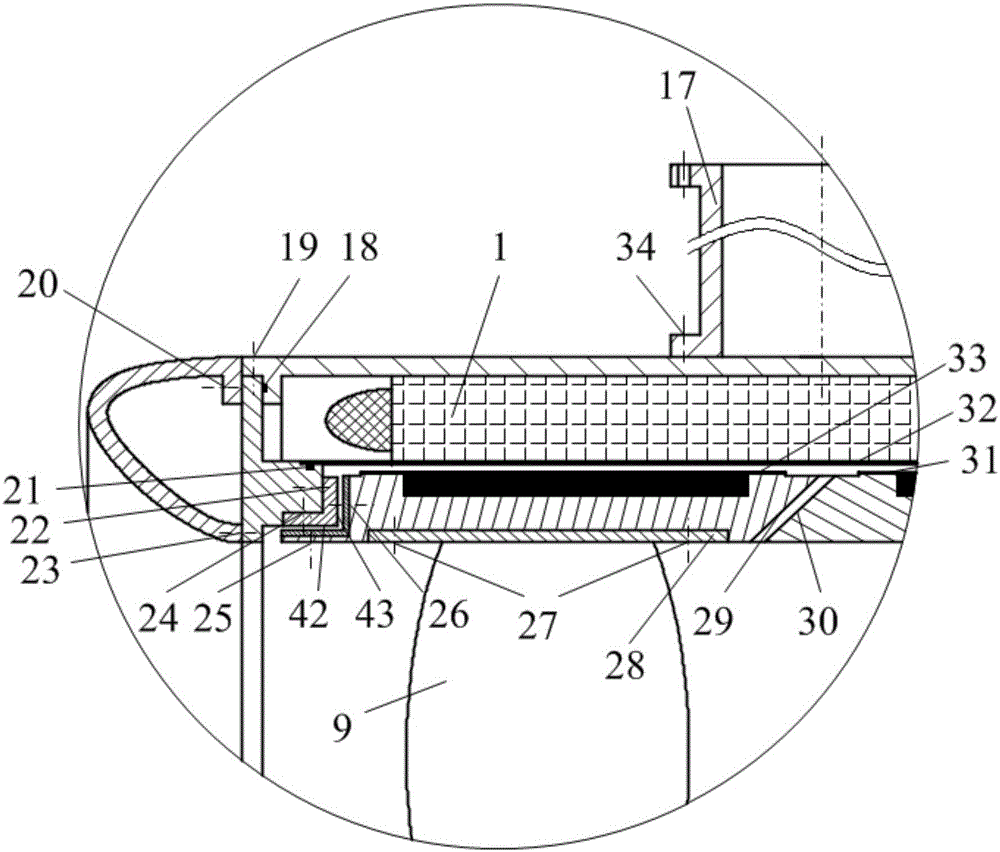

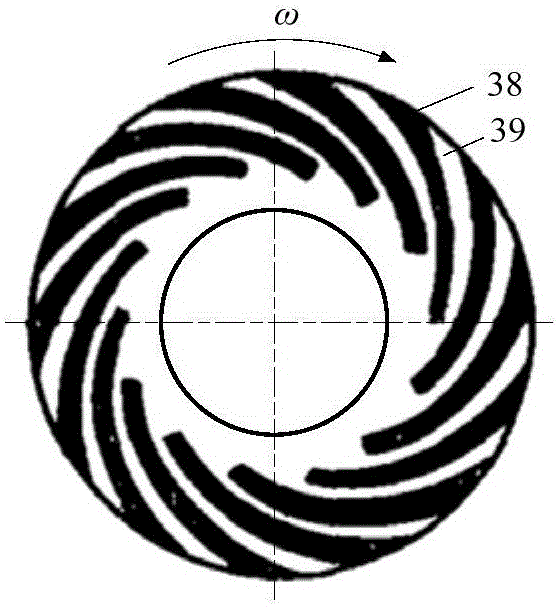

[0029] The counter-rotating shaftless wheel rim drive propeller provided by the invention has a structure such as figure 1 and figure 2 As shown, it consists of five parts: front rotor assembly, rear rotor assembly, conduit assembly, stator winding 1, and bearing assembly, wherein: the front rotor assembly and the rear rotor assembly are respectively installed in the inner cavity of the housing 3 of the conduit assembly, respectively It is supported by bearing assemblies installed at both ends of the conduit assembly; the stator winding 1 is installed in the inner wall of the casing 3 of the conduit assembly, and the inner wall of the stator winding 1 is opposite to the outer walls of the front rotor assembly and the rear rotor assembly; the conduit assembly is connected to the The hulls are connected.

[0030] The fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com