Steel wire framework structure of automobile seat

A steel wire frame and car seat technology, applied in the direction of the seat frame, etc., can solve the problems of reducing the performance of the seat, hidden dangers to personal safety, and easy-to-split covers, so as to improve riding comfort, avoid injuries, and save production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

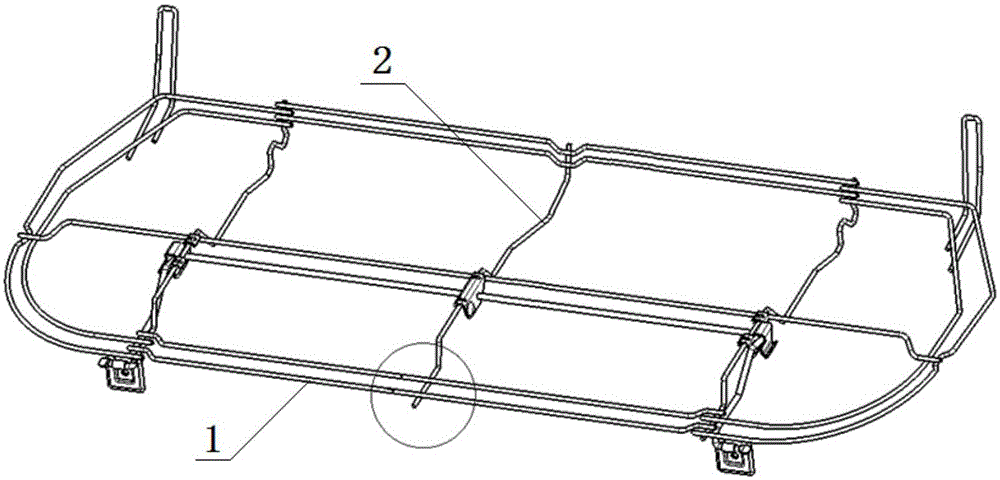

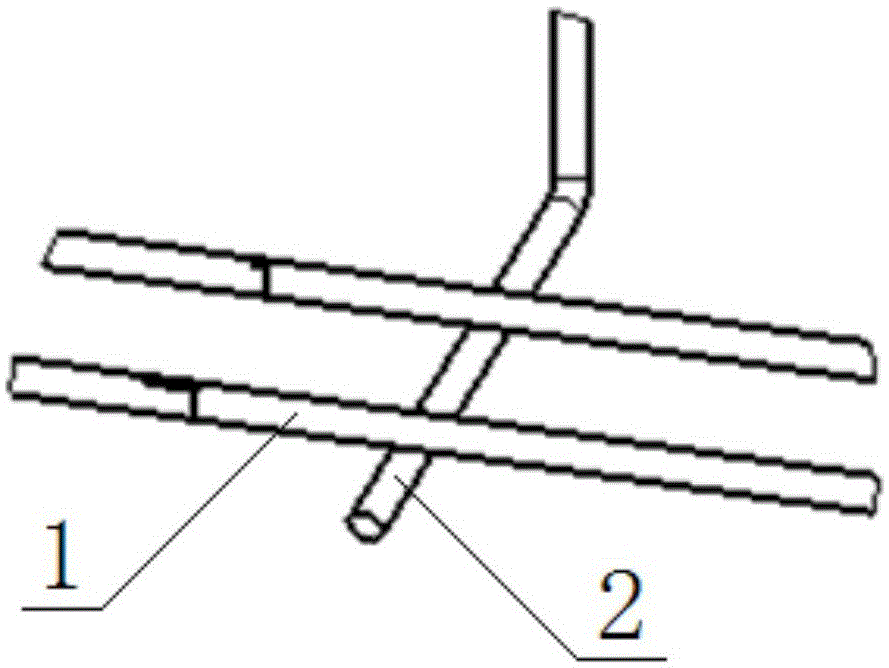

[0015] figure 1 , figure 2 It is a schematic diagram of the existing car seat steel wire skeleton structure, which is represented by figure 1 and figure 2 It can be seen from the combination that the horizontal steel wire and the longitudinal steel wire are straight steel wires at the overlapping position of the horizontal steel wire and the longitudinal steel wire, and the end of the longitudinal steel wire needs to protrude from the horizontal steel wire by 2-3 mm due to welding. The horizontal steel wires cause sharp protrusions. After the fabric is covered, the protrusions are easy to cut the cover and reduce the performance of the seat. At the same time, the sharp protrusions will cause damage to the occupants and bring hidden dangers to personal safety.

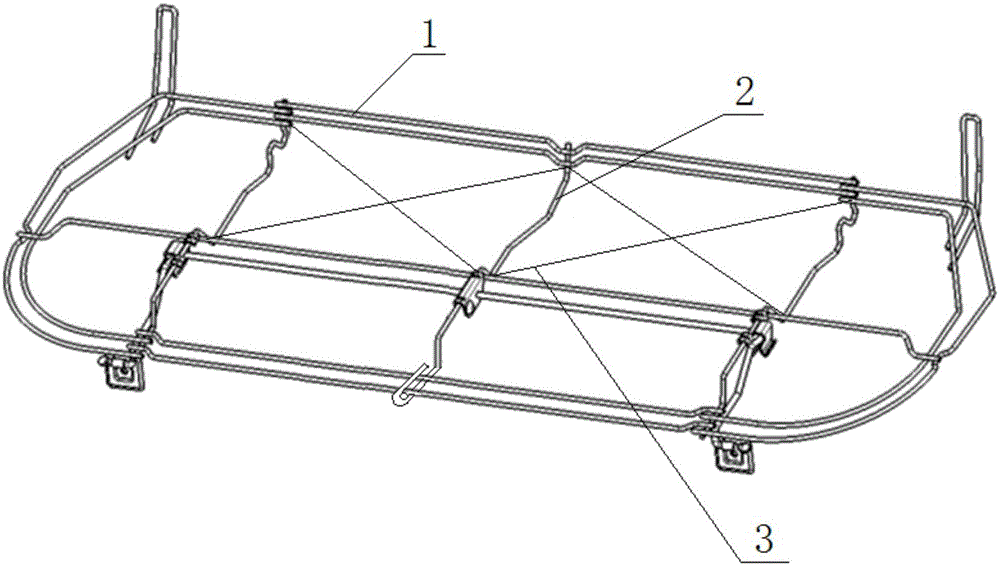

[0016] image 3 It is a structural schematic diagram of the present invention, composed of image 3 It can be seen that the car seat steel wire skeleton structure includes horizontal steel wires 1 and longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com