Strength reinforcing structure for asymmetrical wheel with high-ventilation holes

A technology of strengthening structure and high ventilation, applied in the direction of wheels, spoked wheels, rims, etc., can solve the problems of low structural strength of the hub, poor seismic performance, poor ventilation performance, etc., to improve the seismic performance and ventilation effect, strengthen the strength and Changes in airflow, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

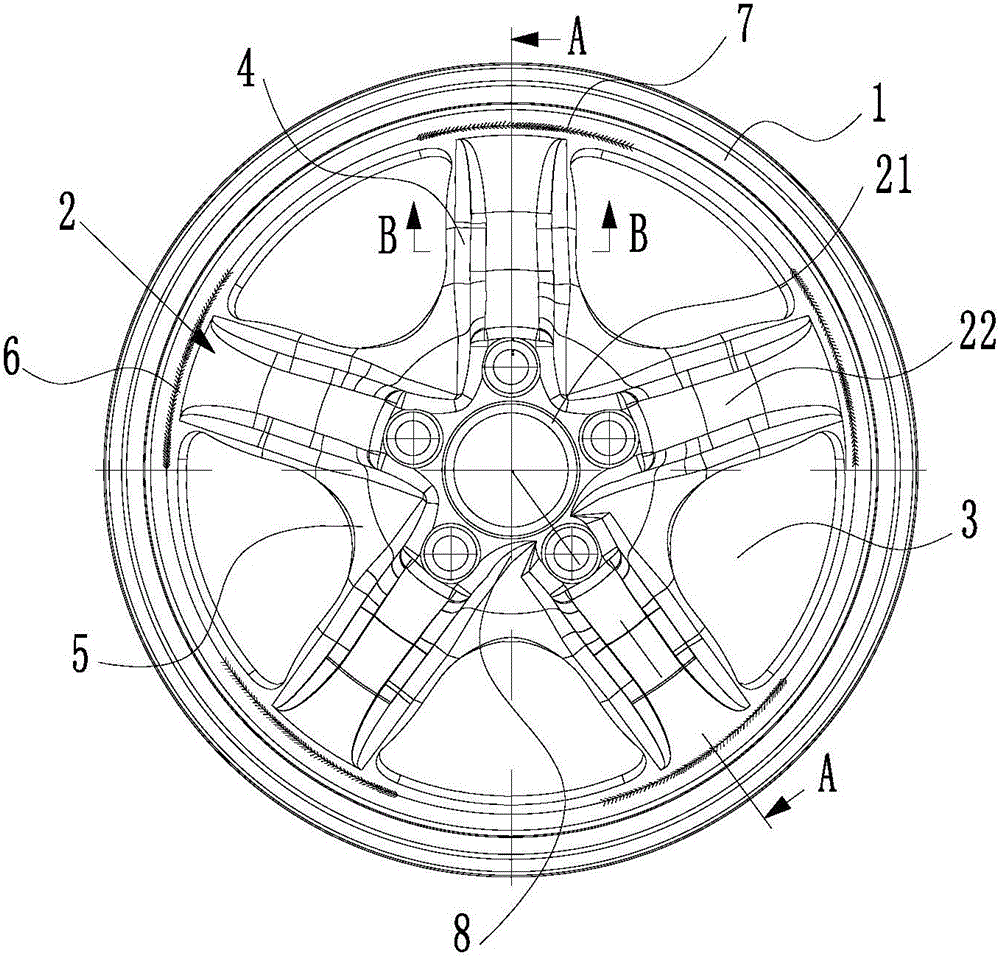

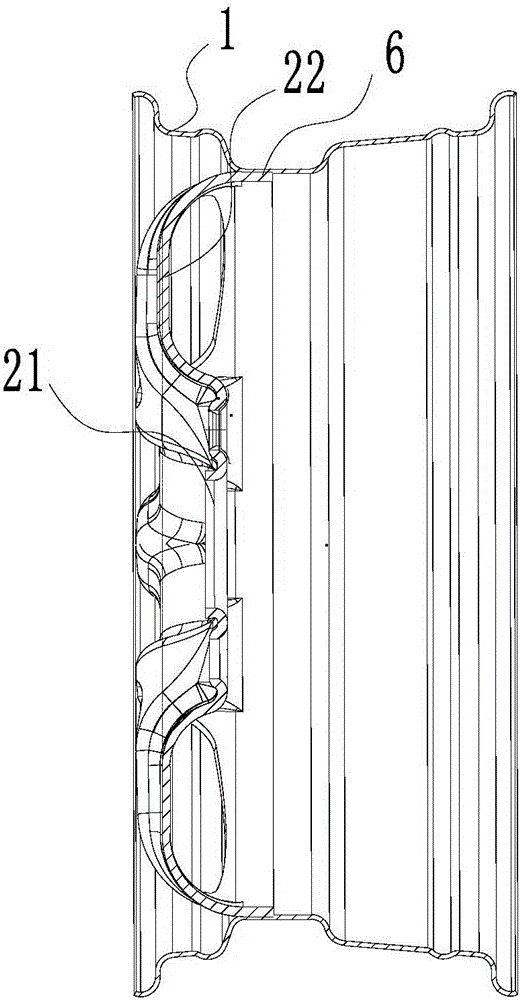

[0020] Such as figure 1 As shown, the strength strengthening structure of an asymmetric high-ventilation wheel of the present invention includes a rim 1 and a spoke 2 fixed on the rim 1, wherein the spoke 2 includes a mounting ring 21 coaxially located in the middle of the rim 1 and an integrated The five spokes 22 connected on the outer ring surface of the mounting ring 21 are uniformly distributed along the outer ring surface of the mounting ring 21, and the connecting ring 6 is coaxially embedded on the inner ring surface of the rim 1. The connecting ring 6 It is fixed on the rim 1 by intermittent welding, so that five sections of intermittent welds 7 are formed on the annular butt joint between the connecting ring 6 and the rim 1. The intermittent welds 7 are located at the outer ends of the spokes 22, and there are two sections of intermittent welds. The seam 7 is deflected clockwise by 10mm relative to the axial center plane of the spoke 22, and the two sections of inter...

Embodiment 2

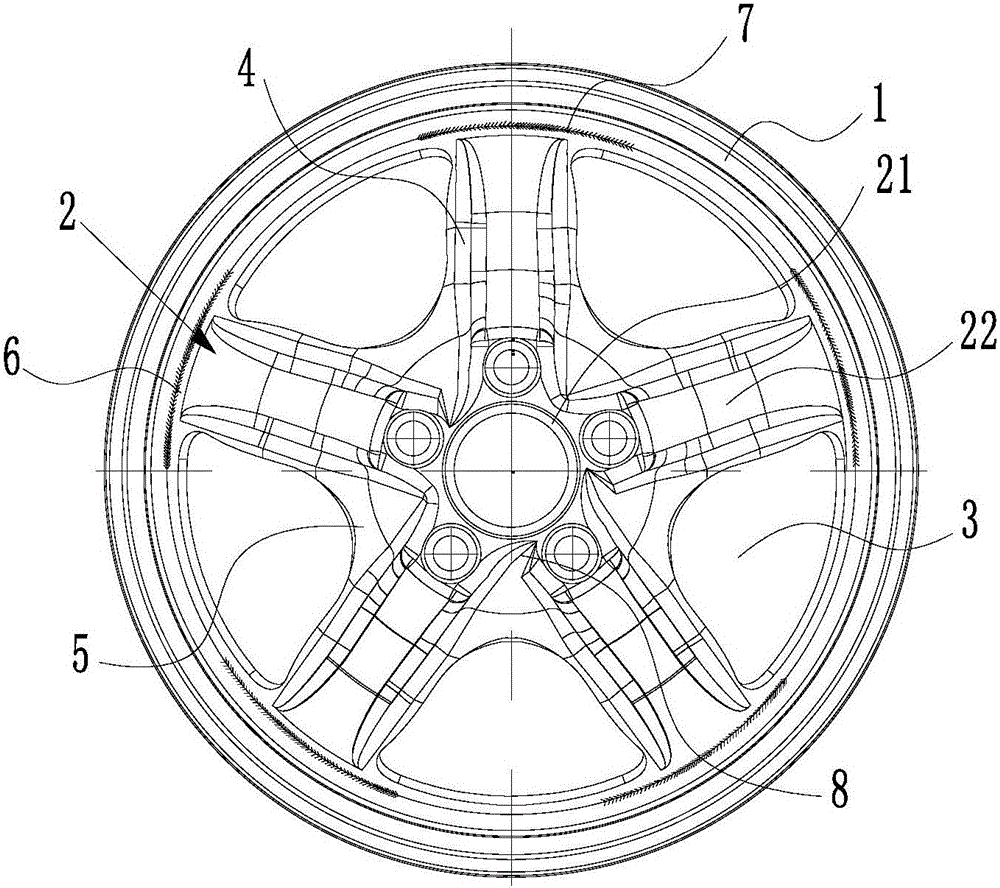

[0022] Such as figure 2 As shown, the top angles 8 on the three inner ribs 5 are deflected counterclockwise by 8mm in the same direction relative to the mid-section of the corresponding spoke 22, and two of the three top angles 8 are adjacent to each other, and the other is spaced apart At the same time, the four side ribs 4 corresponding to the two sides of the two spokes 22 distributed at intervals are 0.8mm thicker than the rest of the side ribs 4, and the rest are exactly the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com