Intelligent high-efficiency smashing device and working method thereof

A high-efficiency crushing and working method technology, applied in the direction of grain processing, etc., can solve the problems of low crushing efficiency and poor crushing quality, and achieve the effects of convenient control, stable working state, and improved crushing quality and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

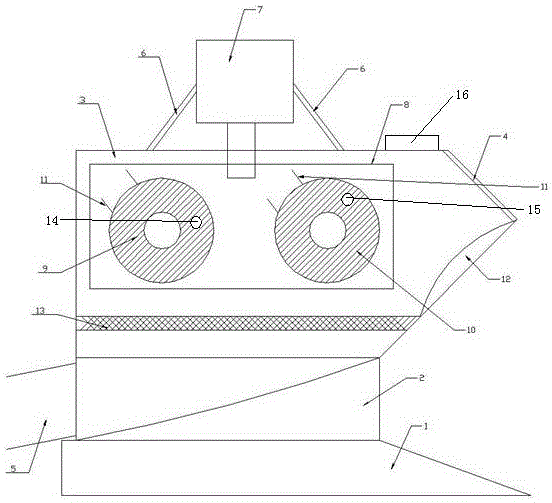

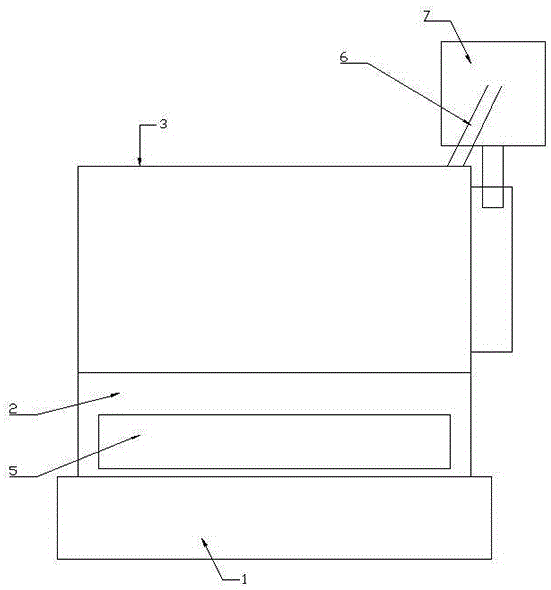

[0023] further as figure 1 , figure 2 and image 3 As shown, another aspect of the present invention provides a working method of an intelligent high-efficiency crushing device. During the crushing operation, the metal material enters the crushing box 3 from the feed port 4, and the controller 16 is used to turn on the drive motor 7 to drive the transmission gearbox 8 for linkage. The rotation of the first crushing shaft 9 and the second crushing shaft 10 drives the crushing teeth 11 to complete the crushing process, and the filter plate 13 plays a screening role; surface structure to increase the crushing speed of the crushed material; among them, in the crushing operation, the controller 16 can be used to control the first crushing shaft 9 and the second crushing shaft 10 to adjust the steering and the speed can be adjusted in real time according to the different raw materials to be crushed (manually or Automatic), and can also be used in combination with the upper comput...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com