Load voltage compensation circuit for light-emitting diode (LED) driving

A technology of LED drive and load voltage, applied in the field of compensation circuit, can solve the problems of increasing circuit cost and achieve the effects of high output current accuracy, simplified application circuit, and simplified peripheral circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

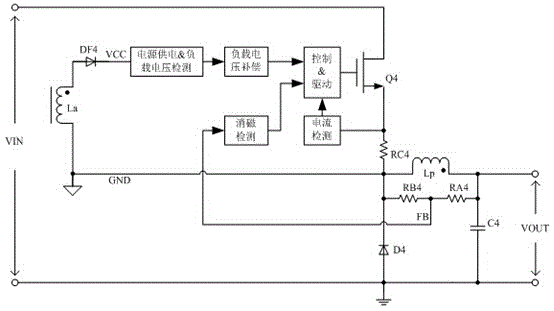

[0019] The working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred solutions.

[0020] as attached Figure 4 Shown is a circuit block diagram of the present invention, specifically a block diagram of a load voltage compensation circuit for LED driving, the circuit includes a transformer, a current detection module, a degaussing detection module, a control drive module, a switch tube (Q6), Sampling resistor (RC6), voltage dividing resistor (RA6, RB6), load voltage detection module, sample hold module and load voltage compensation module. The transformer only includes the main winding (Lp), the load voltage detection module, the sample hold module and the load voltage compensation module are connected in series; the output terminal of the load voltage compensation module is connected to the control drive module; It also leads to a feedback detection terminal (FB), which is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com