Cup-type distribution photovoltaic power generation self-tracking system and control method

A distributed photovoltaic and control method technology, applied in the field of solar tracking systems, can solve problems such as unstable work, complicated operation, and large volume, and achieve the effects of simple structure, small device volume, and strong docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

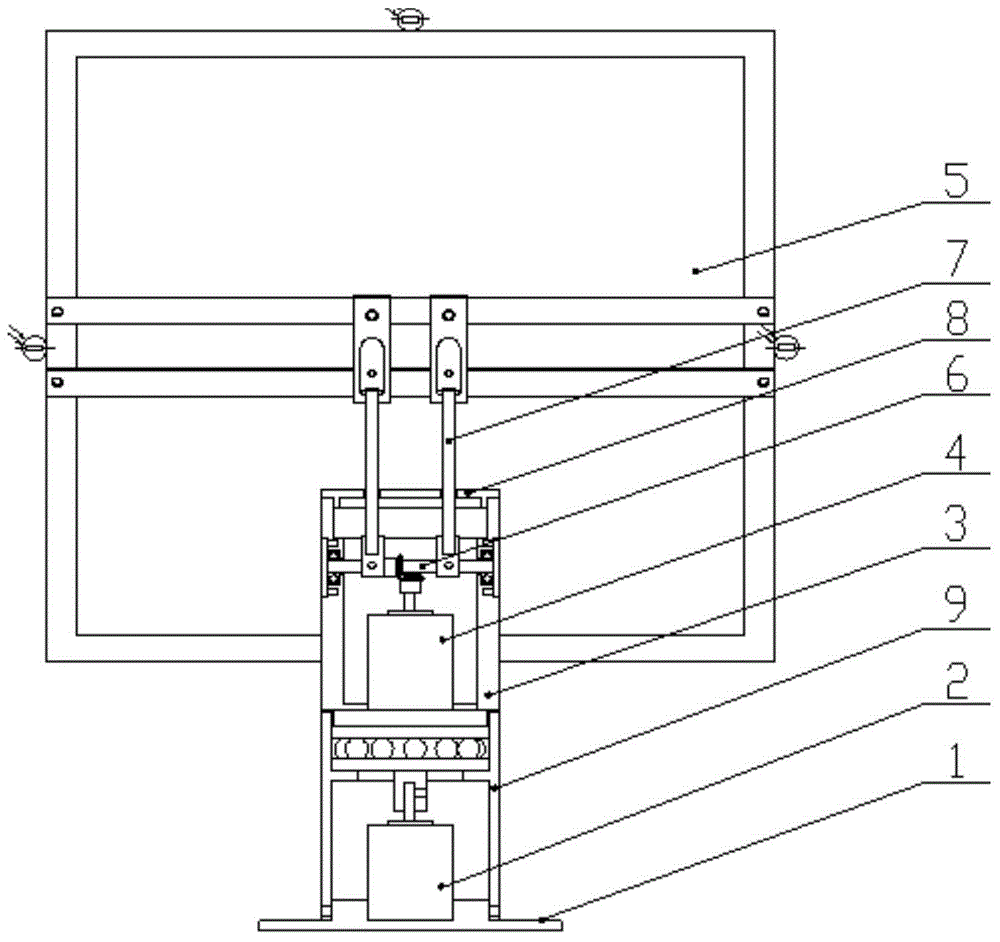

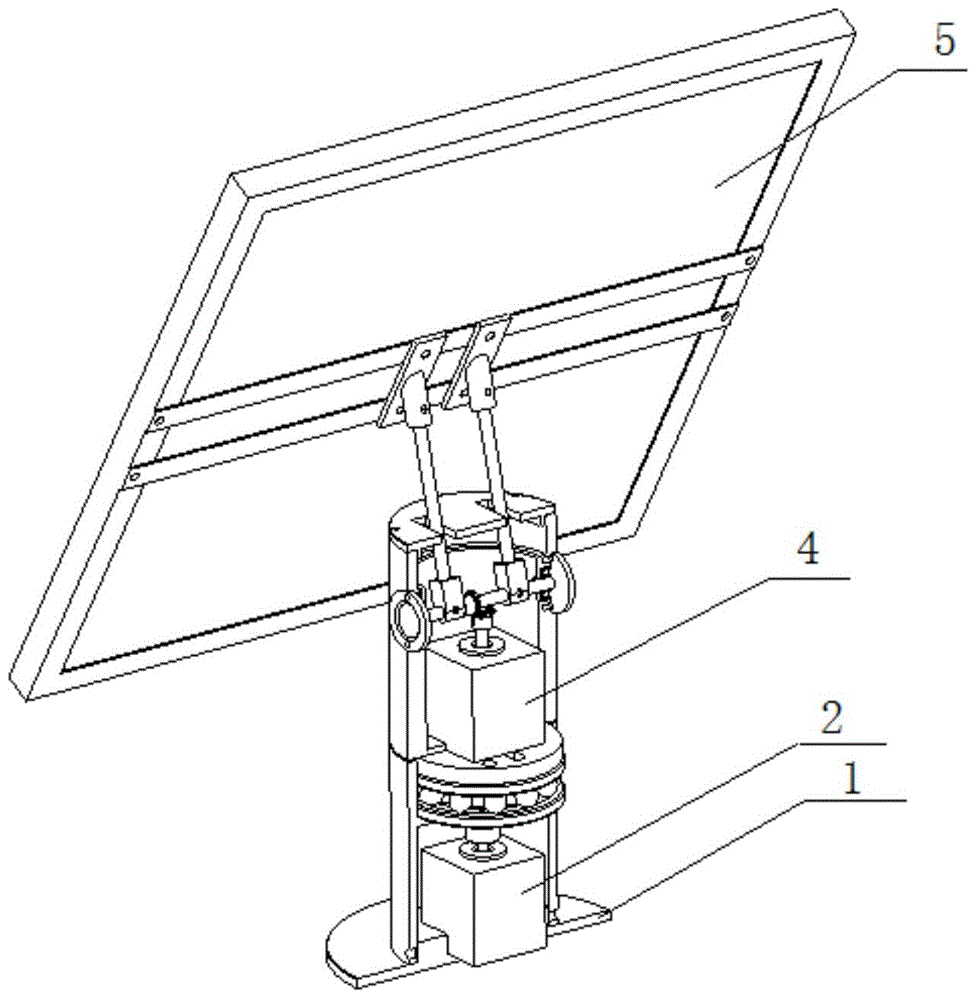

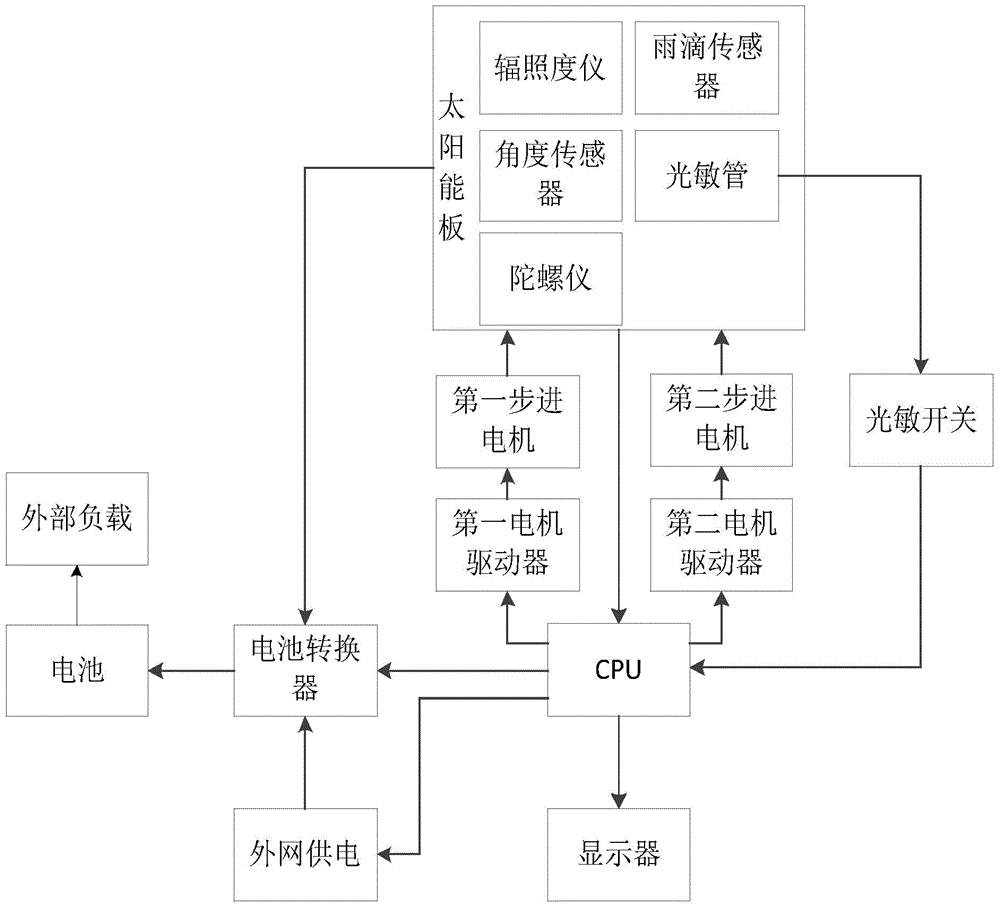

[0039] see figure 1 with figure 2 , a cup-shaped self-tracking system for distributed photovoltaic power generation, including a cup-shaped structure and a control unit; the cup-shaped structure includes a first stepping motor 2 placed on a base 1, and an upper cylinder 3 is arranged on the first stepping motor 2 , the first stepping motor 2 drives the upper cylinder 3 to rotate, and the upper cylinder 3 is provided with a second stepping motor 4, and the second stepping motor 4 can drive the solar panel 5 to do pitching motion by the support rod 7 through the bevel gear transmission mechanism, Photosensitive tubes are arranged on the four sides of the solar panel 5, and the bevel gear transmission mechanism includes the first bevel gear on the second stepping motor 4, and the second bevel gear on the transmission shaft 6, the first bevel gear and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com