Focusing hole plate flowmeter and using method thereof

An orifice flowmeter and orifice flow technology, which is applied in the direction of volume measurement, liquid/fluid solid measurement, volume/mass flow generated by mechanical effects, etc. narrower than other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

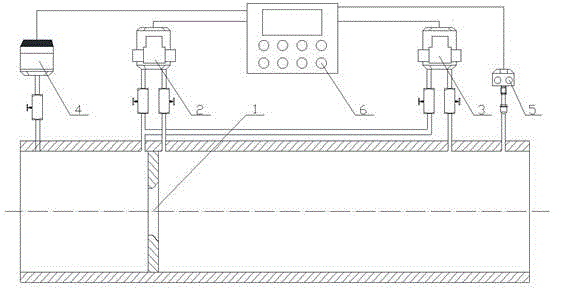

[0027] Such as figure 1 As shown, a focused orifice flowmeter includes an orifice plate 1; a front-end differential pressure transmitter 2, the front-end differential pressure transmitter 2 is installed on the front end of the orifice plate 1, and the differential pressure value before and after the orifice plate 1 is measured (according to Depending on the position of pressure taking, it can be divided into corner joint pressure taking, flange pressure taking, D-D / 2 pressure taking); the rear end differential pressure transmitter 3, the rear end differential pressure transmitter 3 is installed on the orifice plate 1 The rear end measures the pressure loss value of the measured medium after passing through the orifice plate 1; the pressure transmitter 4 is installed on the front end of the orifice plate 1 to measure the pressure value at the front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com