Wiring duct cutting marking-off ruler

A technology for marking rulers and wire slots, which is applied in the field of measuring tools and can solve problems such as troublesome operation and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

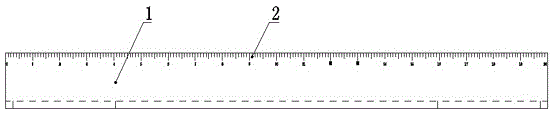

[0014] exist figure 2 Among them, a wire trough cutting ruler, which includes a rectangular measuring ruler body 1 .

[0015] Such as figure 2 As shown, a length marking line 2 is provided on one side of the measuring ruler body 1 along the length direction. For the convenience of measurement, in this embodiment, the first and last scoring lines of the length marking line 2 coincide with both sides of the measuring ruler body.

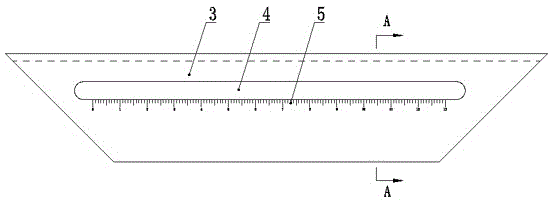

[0016] exist figure 1 Among them, a wire trough cutting marking ruler, which also includes a marking ruler body 3.

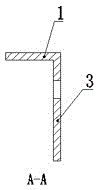

[0017] Such as image 3 As shown, one side of the marking ruler body 3 along the length direction is vertically connected with the other side ruler edge of the measuring ruler body 1 in the same direction to form a right-angle corner ruler.

[0018] exist figure 1 Among them, the ruler edges on both sides of the marking ruler body 3 along the width direction are respectively inwardly inclined at an angle of 45° symmetrically.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com