Improved structure based on ventilation equipment detection port

A technology of ventilation equipment and detection port is applied in the field of improved structure based on the detection port of ventilation equipment, which can solve problems such as poor sealing performance, and achieve the effects of avoiding waste, saving costs and improving sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

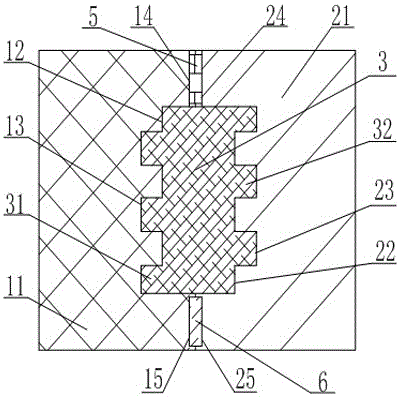

[0019] like figure 1 , figure 2 As shown, based on the improved structure of the detection port of the ventilation device, it includes the detection port 1 arranged on the ventilation device 4, the detection cover 2 matched with the detection port 1, the inner wall of the detection cover 2 is provided with an internal thread, and the width of the internal thread is The outer wall of the detection port 1 is provided with an external thread that cooperates with the internal thread, and the lower end of the external thread on the outer wall of the detection port 1 is provided with an annular bump I11, and the annular bump I11 is recessed inwards. The annular groove I12 matched with the sealing ring 3, three annular grooves III13 are uniformly arranged at the bottom of the annular groove I12, and the side wall of the detection cover 2 is provided with an annular bump II21 cooperating with the annular bump I11, and the annular bump II21 Inwardly recessed to form an annular groove...

Embodiment 2

[0022] This embodiment is on the basis of embodiment 1, as figure 1 , figure 2 As shown, the top of the inner side wall of the annular groove I12 is provided with a groove I14 matching with the sealing ring I5, the top of the outer wall of the annular groove I12 is provided with a groove II15 matching with the sealing ring II6, and the groove II15 of the annular groove II22 The top of the inner wall is provided with groove Ⅲ24 matching with groove Ⅰ14, the top of the outer wall of annular groove Ⅱ22 is provided with groove Ⅳ25 matching with groove Ⅱ15, groove Ⅰ (14), groove Ⅱ15, groove Ⅲ24 , The depth of groove IV 25 is 5mm.

[0023] On the one hand, this embodiment further improves the sealing performance of the test device; on the other hand, it acts as a buffer to prevent the sealing ring 3 from losing its sealing performance due to excessive compression.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com