Transformation method for boiler

A boiler transformation and burner technology, which is applied in the combustion method, the use of multiple fuel combustion, lighting and heating equipment, etc., can solve the problem of rare transformation methods, and achieve the effects of simple transformation methods, resource saving and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

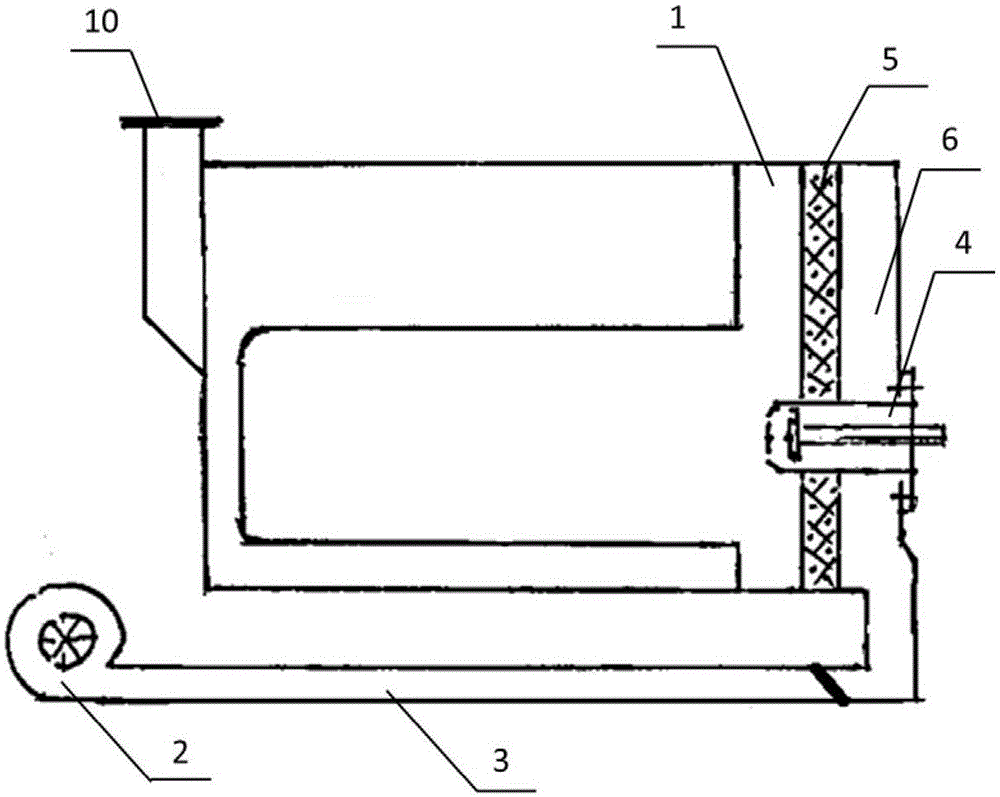

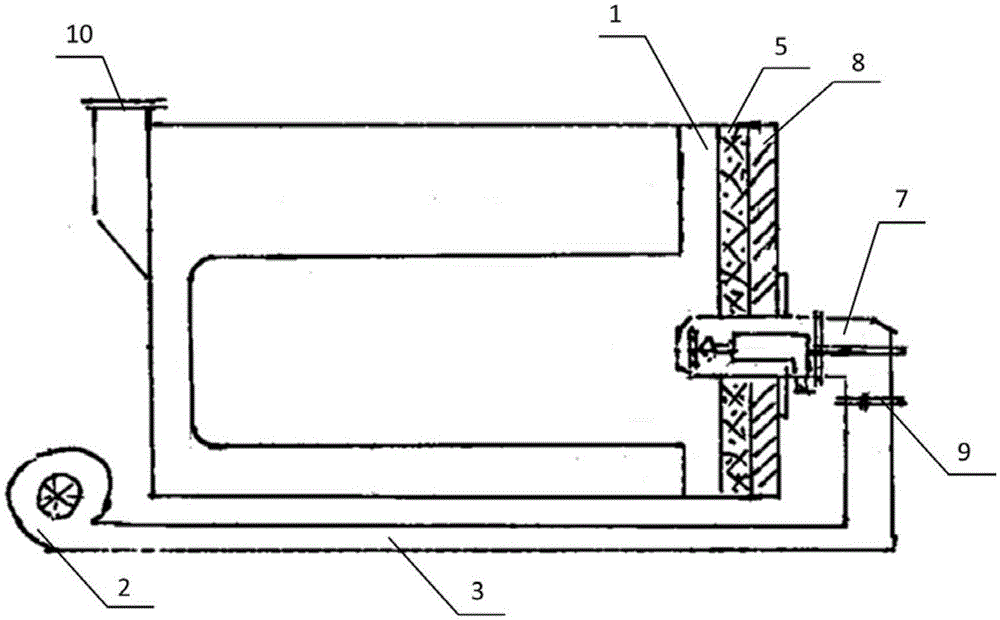

[0021] An external oil-gas dual-fuel burner boiler in a preferred embodiment of the present invention is transformed from the original built-in oil-fired burner boiler, which is a central back-firing three-pass boiler , The evaporation capacity of the boiler is 12 tons / hour, the steam supply pressure is 1.0Mpa, the furnace diameter of the boiler is 1700mm, the length of the furnace is 4150mm (the distance from the bottom of the furnace to the flame stabilization plate), and the boiler is equipped with a 30kw external blower.

[0022] Such as figure 1 As shown, the original built-in oil burner boiler includes front back combustion chamber 1, built-in oil burner 5, blower 2, air duct 3, interlayer air chamber 6, flue gas outlet 10, front back combustion chamber 1 and interlayer air chamber 6 is provided with a refractory wall 5, the blower 2 communicates with the interlayer air chamber 6 through the air duct 3, the built-in fuel burner 4 is arranged in the interlayer air chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com