Improved structure of the sealing device to avoid air leakage from the detection port

A sealing device and detection port technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of air leakage and poor sealing performance of the detection port, and achieve the effect of ensuring the sealing effect, improving work efficiency and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

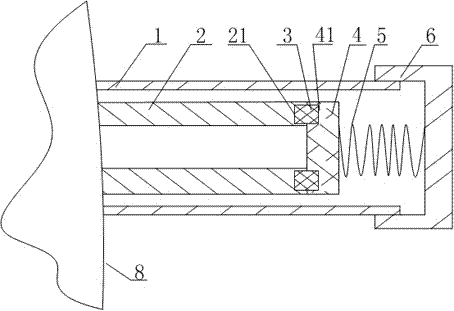

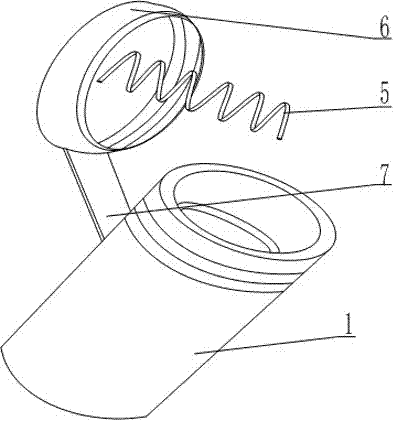

[0019] Such as figure 1 , figure 2 As shown, the improved structure of the sealing device to avoid air leakage at the detection port includes the detection port 2 and the detection cover 4 on the ventilation device 8. Groove Ⅱ41 that cooperates with the sealing ring 3, the detection port 2 is covered with a fixed cylinder 1, the height of the fixed cylinder 1 is higher than the detection port 2, the height difference is set to 10mm ~ 15mm, between the inner wall of the fixed cylinder 1 and the outer wall of the detection port 2 An annular gap is formed, and the width of the annular gap is set at 5 mm to 10 mm. The top of the fixed cylinder 1 is provided with an external thread, and the fixed cylinder 1 is equipped with a fixed cover 6. The inner wall of the fixed cover 6 is provided with an internal thread that matches the external thread. , The fixed cover 6 is provided with a spring 5 inside, and the natural length of the spring 5 is greater than the distance between the f...

Embodiment 2

[0022] This embodiment is on the basis of embodiment 1, as figure 1 , figure 2 As shown, the fixed cover 6 is arranged on the fixed cylinder 1 through the connecting piece 7, and the connecting piece is a plastic sheet.

[0023] The setting of the connecting piece 7 is convenient for opening and closing of the fixed cover 6 on the fixed cylinder 1, which makes the operation more convenient and improves the work efficiency.

Embodiment 3

[0025] This embodiment is on the basis of embodiment 1, as figure 1 , figure 2 As shown, the fixed cover 6 is arranged on the fixed cylinder 1 through the connecting piece 7, and the connecting piece is an aluminum sheet.

[0026] The setting of the connecting piece 7 facilitates the opening and closing of the fixed cover 6 on the fixed cylinder 1, which makes the operation more convenient and improves the work efficiency. The aluminum sheet has certain elasticity and can satisfy the opening and closing of the fixed cover 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com