Air cylinder with non-rotatable piston and non-rotatable piston rod

A piston rod and piston technology, applied in fluid pressure actuating devices, etc., can solve problems such as difficult work, complex structure, and affecting the service life of cylinders, and achieve the effects of wear balance, reduced wear, and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

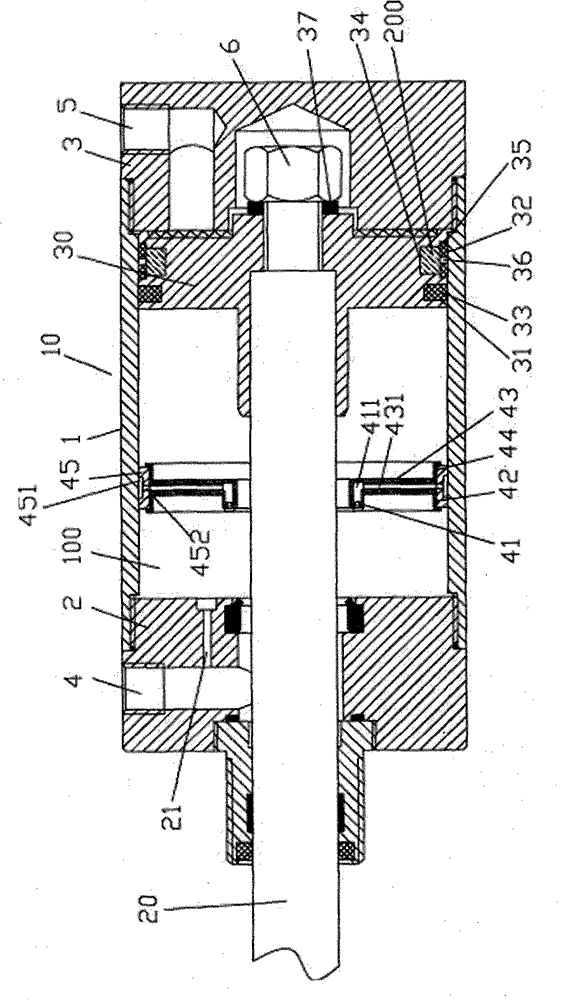

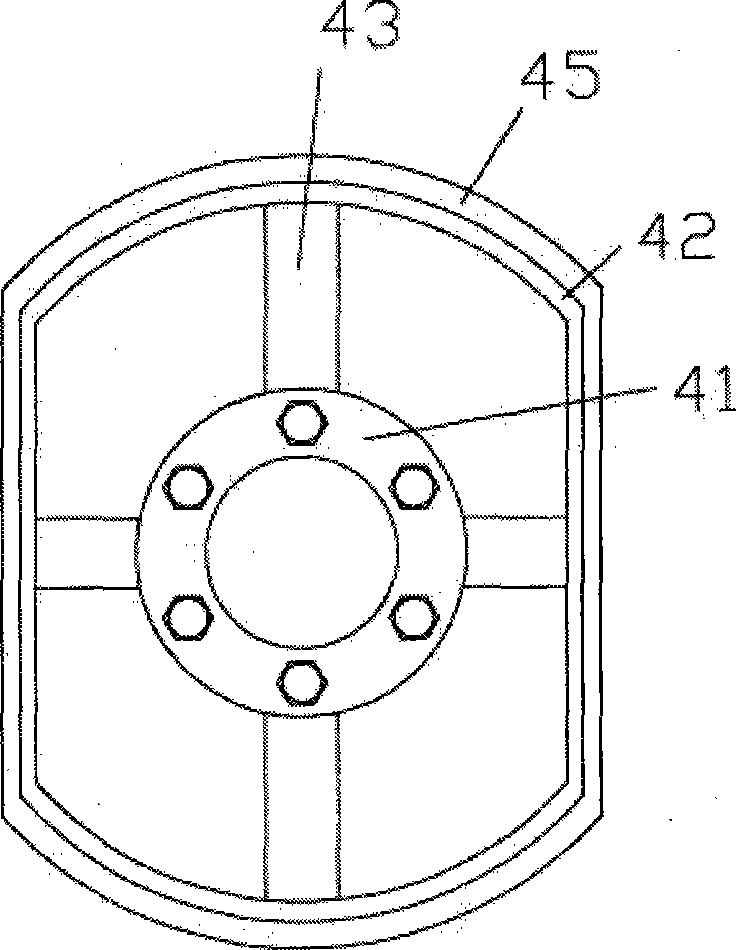

[0019] Examples, see e.g. Figures 1 to 2 As shown, a cylinder with a non-rotatable piston and piston rod is composed of a cylinder body 10 and a piston rod 20 disposed in the cylinder body 10. The cylinder body 10 has a straight cylindrical inner cavity 100, and the piston 30 is fixed on On the piston rod 20 , the outer surface of the piston 30 is in close contact with the side wall of the inner chamber 100 of the cylinder 10 , and the cross sections of the inner chamber 100 and the piston 30 are both waist-shaped holes.

[0020] Described cylinder body 10 comprises cylinder body 1, front end cover 2 and rear end cover 3, and the front end of cylinder body 1 is fixed with front end cover 2, and the rear end of cylinder body 1 is fixed with rear end cover 3, and the side of front end cover 2 is provided with Exhaust hole 4, air inlet hole 5 is arranged on the side of rear end cover 3.

[0021] The rear end of the piston rod 20 is screwed and fixed with a piston 30 and a fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com