Two-stage double-spring direct relief valve and control method thereof

A direct-acting relief valve, double-spring technology, used in safety valves, balance valves, valve devices, etc., can solve problems such as wear and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

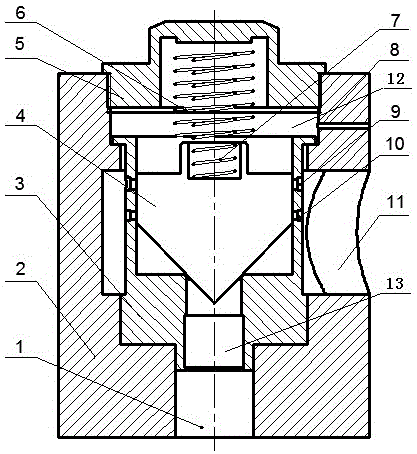

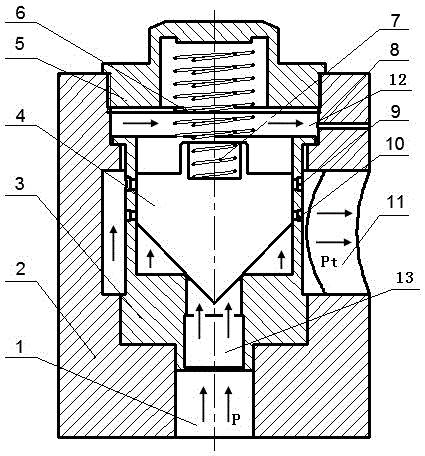

[0033] Such as Figure 1-2 As shown, the embodiment of the present invention provides a two-stage double-spring direct-acting overflow valve, which includes a valve body 2, and a stepped accommodation cavity is provided in the middle of the valve body 2 along the longitudinal direction. There is a valve seat 3 which slides in cooperation with the accommodation chamber, the bottom surface of the valve seat 3 and the bottom opening of the valve body 2 form an oil inlet 1; Oil port 1, the oil inlet 1 extends inward to one side of the valve seat 3; a valve core 4 is provided in a sliding sleeve inside the valve seat 3, and the width of the upper part of the valve core 4 is smaller than that of the middle part of the valve core 4 The lower part of the spool 4 is conical, and the lower part of the spool 4 is connected with the conical hole 13 that r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com