Acrylonitrile-butadiene rubber and phenolic resin blended foamed sponge and preparation method thereof

A technology of foaming sponge and nitrile rubber is applied in the field of blending foaming sponge of nitrile rubber and phenolic resin and its preparation, which can solve the problems of escape personnel hazards, toxic HCL and CI2 gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A preparation method of nitrile rubber and phenolic resin blended foamed sponge, which specifically comprises:

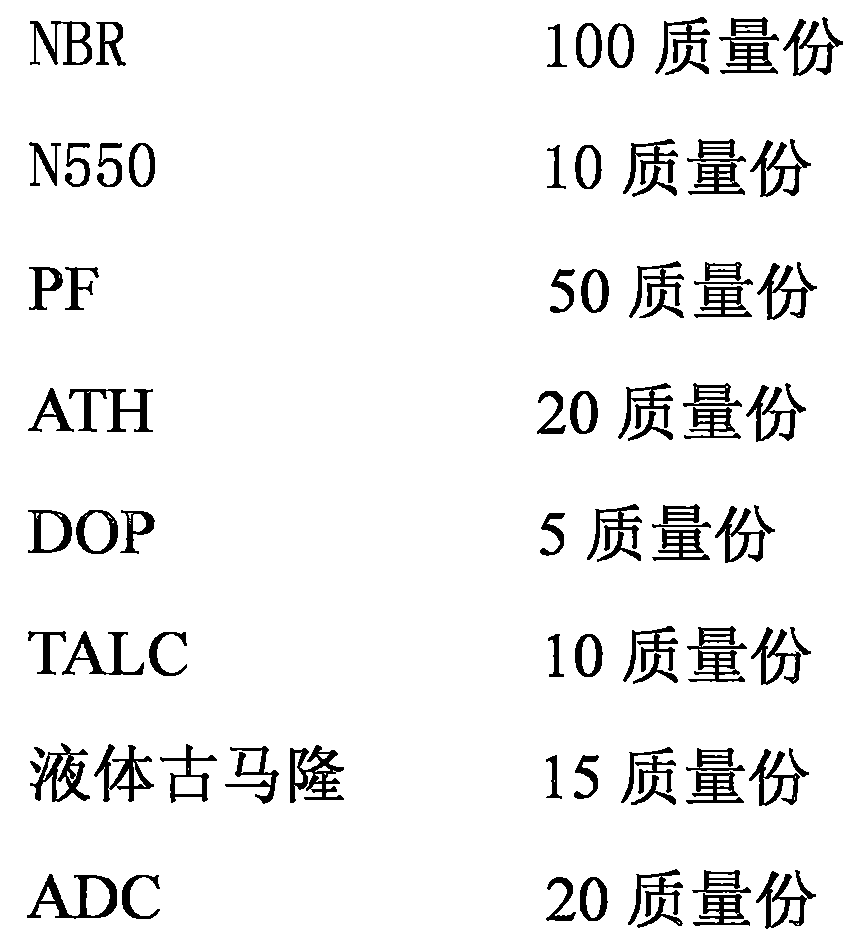

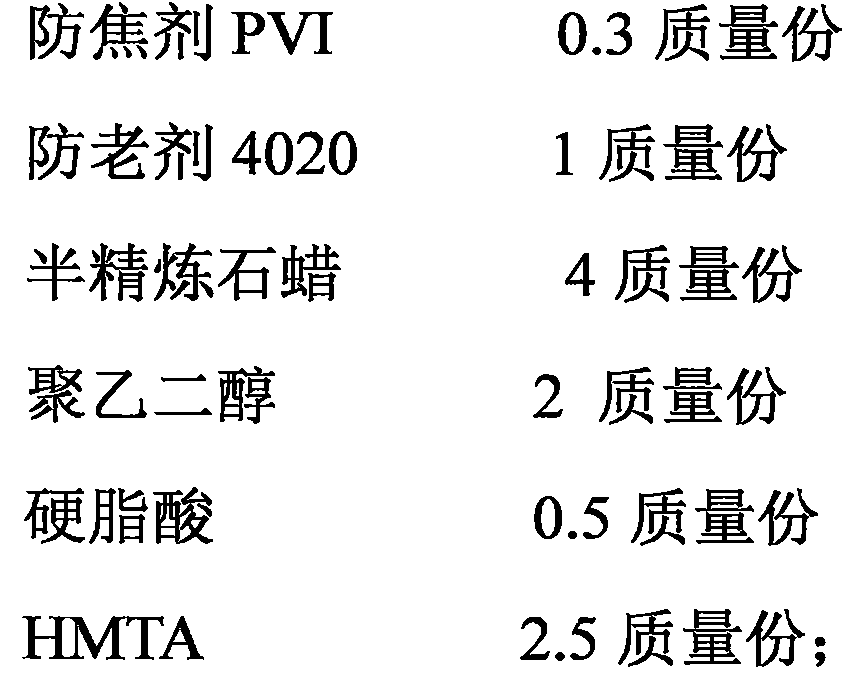

[0024] Step 1: Prepare high-temperature rubber compound, the specific composition ratio is as follows:

[0025]

[0026]

[0027] The above components are respectively put into the kneader for pressurized kneading and blending. When the temperature reaches 151°C, the materials are turned into the kneading mechanism to obtain high-temperature compounded rubber tablets;

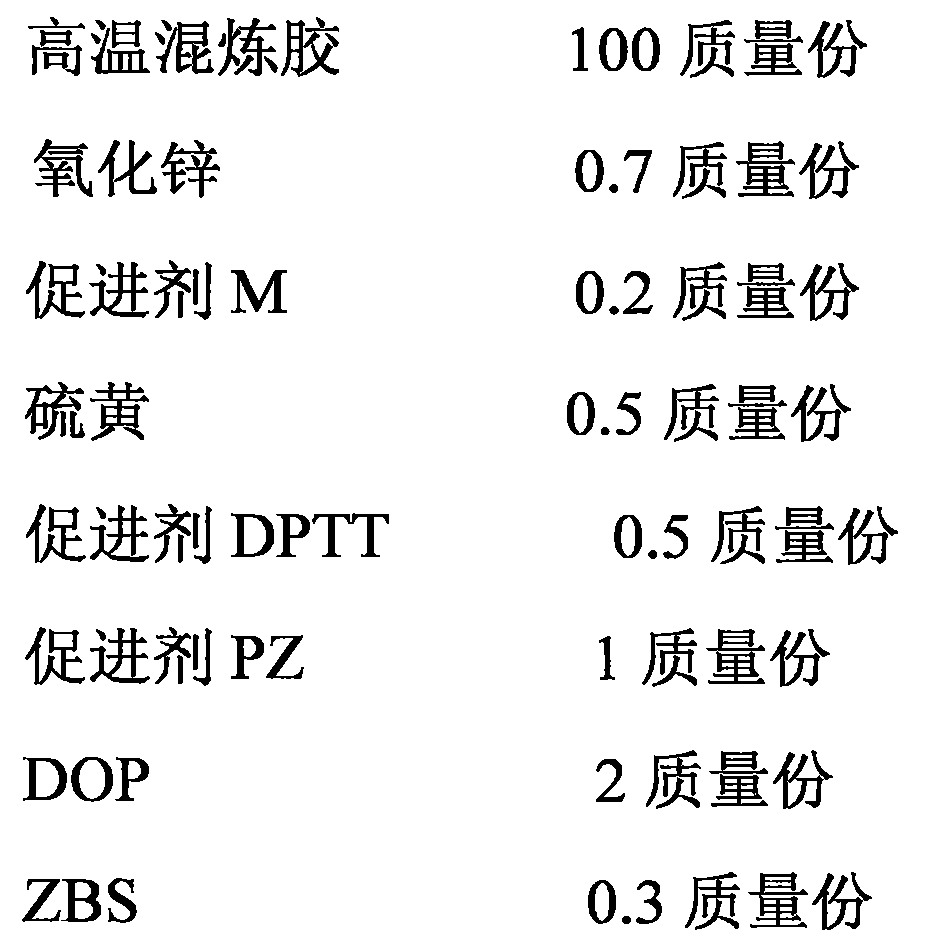

[0028] Step 2: Prepare molding compound rubber, the specific component ratio is as follows:

[0029]

[0030] The above components are respectively put into the kneader and kneaded for 2.5 minutes under pressure, and the output material is pressed into the kneading machine to form a molded mixing rubber strip, which is blown to cool for later use;

[0031] Step 3: Extrude, vulcanize and foam to obtain a foamed sponge; specifically include the following process steps:

[0032] 1) Fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com