Purification method of chromatographic grade methanol

A purification method and chromatographic-level technology, which is applied in the field of solvent purification, can solve the problems of high-purity methanol dependence on imports, high degree of containment, and low methanol output, and achieve stable operation, simple production process, and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

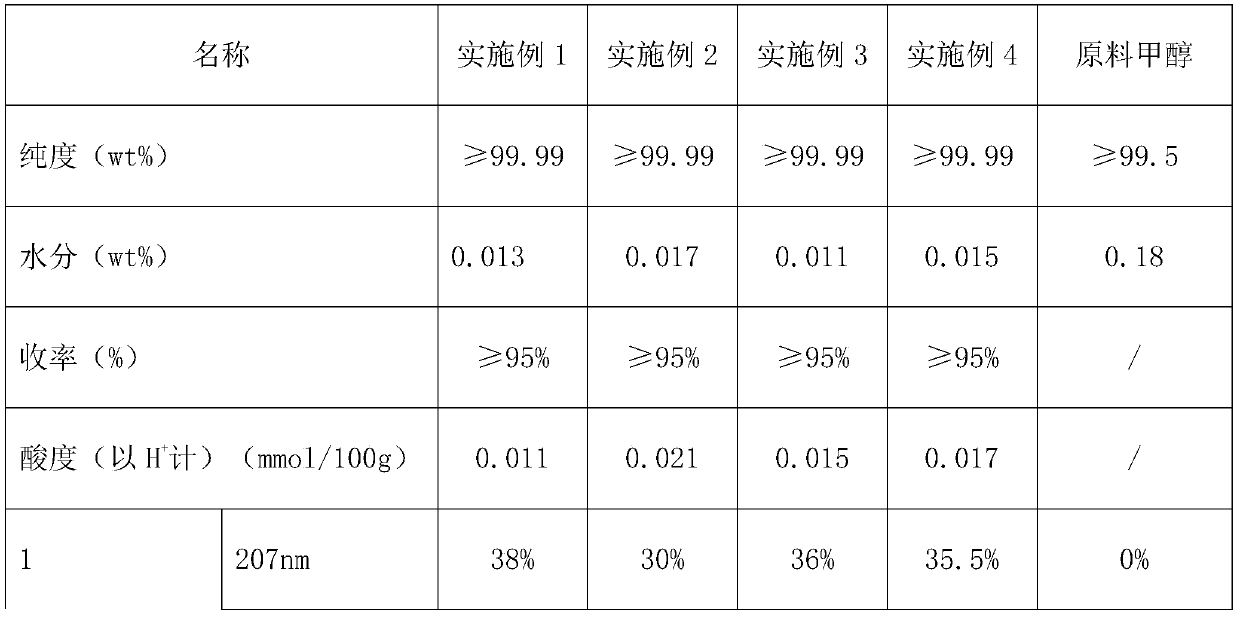

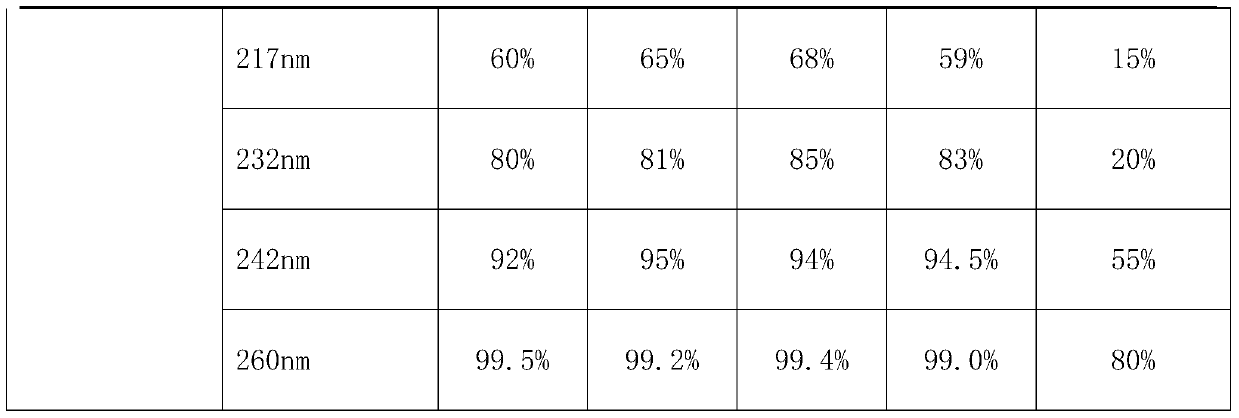

Examples

Embodiment 1

[0020] The purification method of chromatographic grade methanol comprises the steps:

[0021] a. get the raw material methyl alcohol that purity is 99.5% (wt), add sodium carbonate to make the solution p Adjust the H to 7, and shake to make the sodium carbonate fully react with the acidic impurities in the raw material methanol to form a salt precipitate; stand for stratification, discard the water layer and the precipitate, filter the organic layer, and keep the filtrate.

[0022] b. Adsorption:

[0023] 1. The above-mentioned filtrate is passed into the adsorbent column that particle diameter is 50 order 3A molecular sieves with the speed of 0.5 column volume / hour, further removes the moisture in the organic layer; After adsorption, the methanol water content is controlled at≤0.03%; In the step, the molecular sieve is used to remove the moisture in the methanol after extraction. If the moisture content is >0.03%, the molecular sieve needs to be replaced before continuing t...

Embodiment 2

[0029] The purification method of chromatographic grade methanol comprises the steps:

[0030] a. get the raw material methyl alcohol that purity is 99.5% (wt), add Potassium Hydroxide and adjust the pH of solution to 8, and shake and make Potassium Hydroxide and the acidic impurity in the raw material methanol fully react, generate salt precipitate; Static Separate the layers, discard the aqueous layer and precipitate, filter the organic layer, and keep the filtrate.

[0031] b. Adsorption:

[0032] 1. The above-mentioned filtrate is passed into the adsorbent column that particle diameter is 20 order 3A molecular sieves with the speed of 30 column volumes / hour, further removes the moisture in the organic layer; After adsorption, the methanol water content is controlled at≤0.03%; In the step, the molecular sieve is used to remove the moisture in the methanol after extraction. If the moisture content is >0.03%, the molecular sieve needs to be replaced before continuing the mol...

Embodiment 3

[0038] The purification method of chromatographic grade methanol comprises the steps:

[0039] a. get the raw material methyl alcohol that purity is 99.5% (wt), add sodium oxide and adjust the pH of solution to 7.5, and shake to make the acidic impurities in sodium oxide and raw material methanol fully react, generate salt precipitate; layer, discard the aqueous layer and precipitate, filter the organic layer, and keep the filtrate.

[0040] b. Adsorption:

[0041] 1. the above-mentioned filtrate is passed into the adsorbent column that the particle size is 100 mesh molecular sieves with the speed of 15 column volumes / hour, and further removes the moisture in the organic layer; after the adsorption, the methanol water content is controlled at≤0.03%; this step Use molecular sieve to remove the moisture in methanol after extraction, if the moisture content > 0.03%, you need to replace the molecular sieve and then continue the molecular sieve adsorption treatment;

[0042] II. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com