Active sludge adsorption bed design method

A technology for activated sludge adsorption and design methods, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as failure, reduce organic matter content, better absorb organic matter, The effect of improving the B/C ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

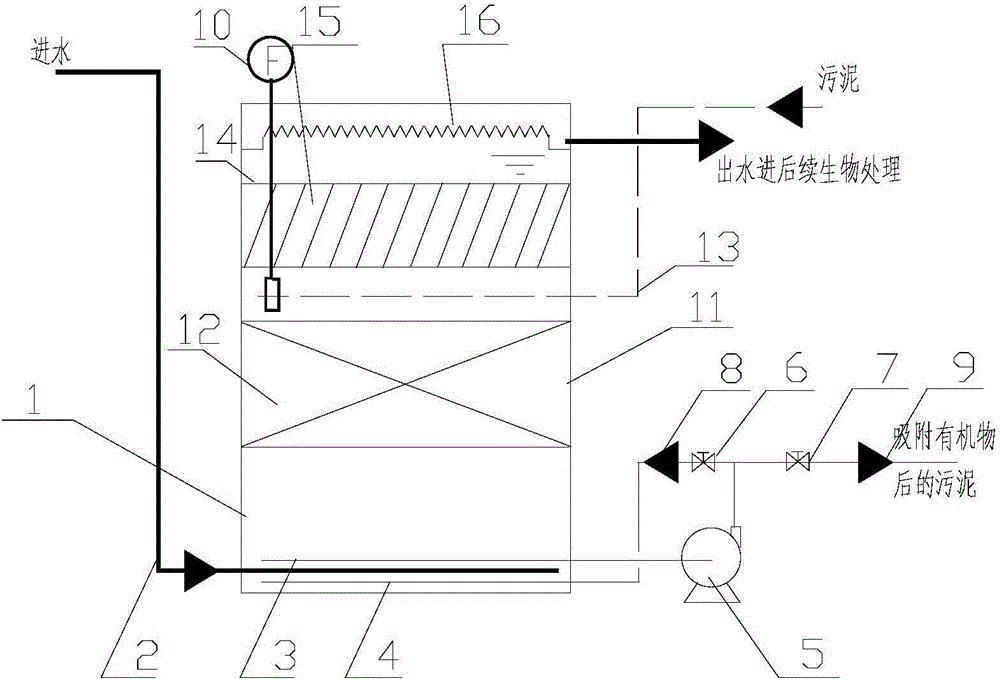

Image

Examples

Embodiment 1

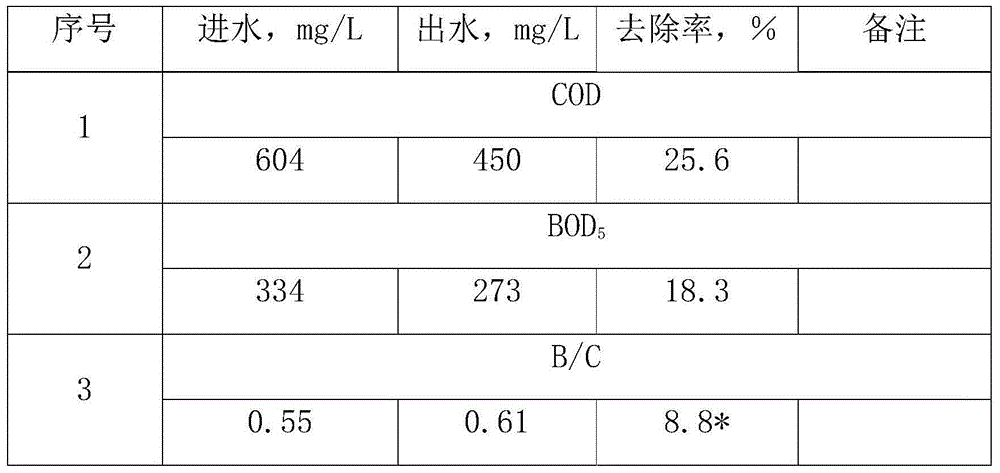

[0059] See Table 1 for the treatment effect of a certain petrochemical wastewater using the activated sludge adsorption bed of the present invention.

[0060] Table 1

[0061]

[0062] *: B / C increase rate.

[0063] 1. The sludge adsorption bed is 12 meters high and 10 meters in diameter. The adsorption layer (sludge adsorption layer) in the sludge adsorption bed is equipped with a 2-meter-high soft filler, and the bottom of the filler is 6 meters away from the bottom of the sludge adsorption bed. The upper separation layer (mud-water separation layer) is equipped with inclined pipe packing with a height of 1.0 meters.

[0064] The mass (grams) of the soft filler is 1.5g per bundle, the diameter is 120mm, the vertical spacing (assembly distance) is 60mm, and the left and right spacing of each filler is 150mm.

[0065] 2. After aerobic biological treatment, the remaining sludge in the secondary sedimentation tank enters intermittently from about 5 meters in the middle of ...

Embodiment 2

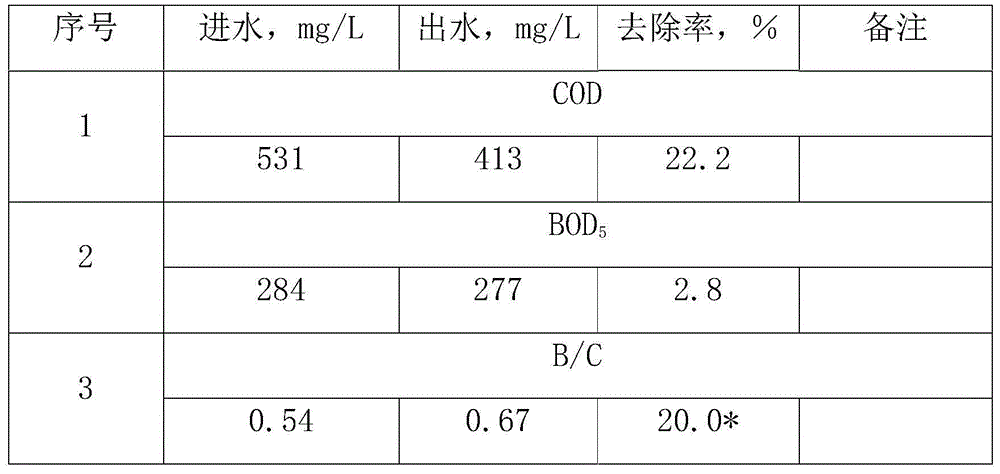

[0078] See Table 2 for the treatment effect of a certain chemical industry wastewater using the activated sludge adsorption bed of the present invention.

[0079] Table 2

[0080]

[0081] *: B / C increase rate.

[0082] 1. The size of the sludge adsorption bed is 30 x 20 x 5 meters in length x width x height, divided into 2 grids. The adsorption layer is equipped with a 2-meter-high soft filler, and the bottom of the filler is 3.0 meters away from the bottom of the sludge adsorption bed. Water overflows.

[0083] The mass (grams) of the soft filler is not less than 1.5g per bundle, the diameter is 150mm, the vertical distance is 60mm, and the left and right distance between each filler is 180mm.

[0084] 2. After aerobic biological treatment, the remaining sludge in the secondary sedimentation tank enters intermittently from about 3 meters in the middle of the sludge adsorption bed, 1-2 times a day, with a flow rate of 80 meters 3 / Time.

[0085] The diameter of the mu...

Embodiment 3

[0096] See Table 3 for the treatment effect of a certain chemical industry wastewater using the activated sludge adsorption bed of the present invention.

[0097] table 3

[0098]

[0099] *: B / C increase rate.

[0100] 1. The sludge adsorption bed is 8 meters high and 12 meters in diameter. The sludge adsorption bed is equipped with a 2-meter-high soft filler, and the bottom of the filler is 4 meters from the bottom of the sludge adsorption bed. The upper part of the sludge adsorption bed is equipped with sloping plate packing with a height of 1 meter.

[0101] The mass (grams) of the soft filler is 1.5g per bundle, with a diameter of 120mm, an upper and lower spacing of 60mm, and a left and right spacing of each filler of 150mm.

[0102] 2. After aerobic biological treatment, the remaining sludge in the secondary sedimentation tank enters intermittently from about 5 meters in the middle of the sludge adsorption bed, 3 times a day, with a flow rate of 20 meters 3 / Time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com