Jack synchronously and electrically driven

An electric drive, jack technology, applied in the direction of lifting devices, etc., can solve the problems of laborious operation and heavy force of the operator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

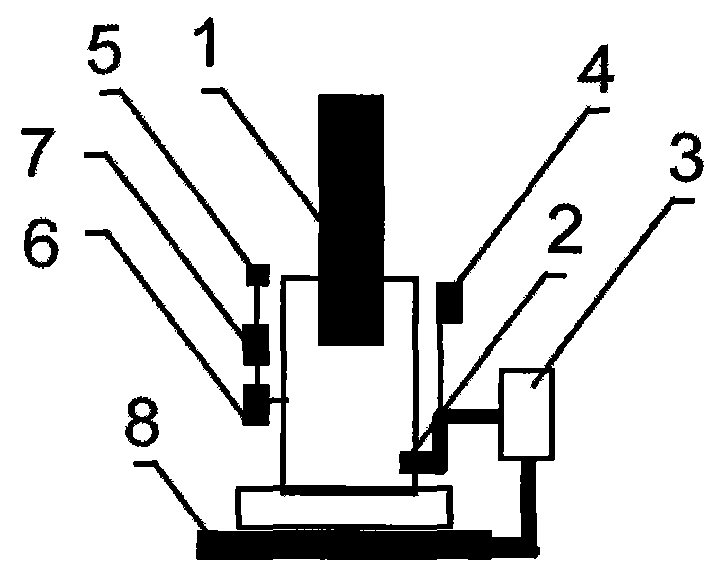

[0012] Embodiment: as shown in the accompanying drawing. For synchronous electric drive jacks, an electric device [3] is installed on the starting lever [2] of the jack [1]. The electric device is a reciprocating rotary structure. Pressurize the jack.

[0013] Synchronously electrically driven jacks, a limit device [4] is set to automatically control the lifting limit position of the jack.

[0014] Synchronously electrically driven jacks, set up an electronic monitoring system [5] to remotely monitor the jacking status, and the electronic monitoring system observes the site conditions through a monitor [6].

[0015] Synchronously electrically driven jacks, a pressure detection module [7] is set to detect the pressure state of each jack.

[0016] The synchronous electric driven jack is equipped with a jack bearing block [8] to ensure the stability and balance of the foundation when the jack is used.

[0017] The jacks driven by the synchronous electric power mentioned above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com