Vertical air pressure control system of air bearing table and control method thereof

A technology of air pressure control and air flotation platform, which is applied in space navigation equipment, simulation device of space navigation conditions, transportation and packaging, etc. The effect of convenient control, simple structure and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

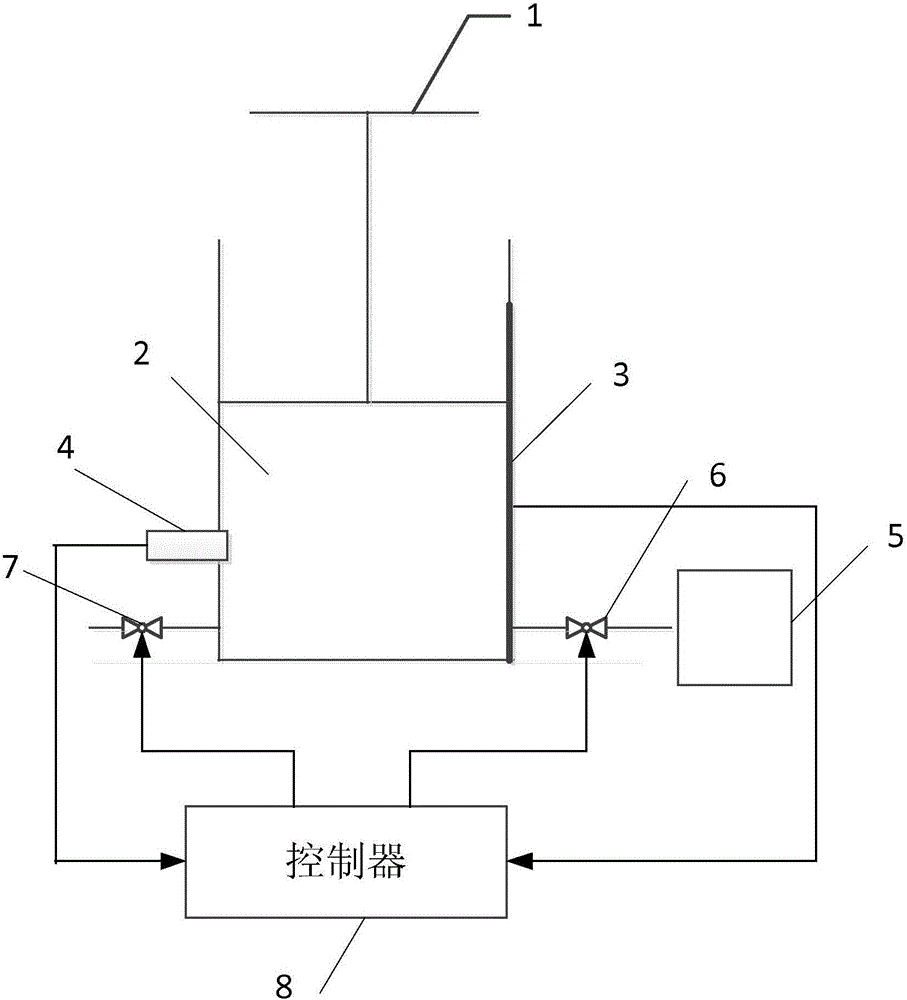

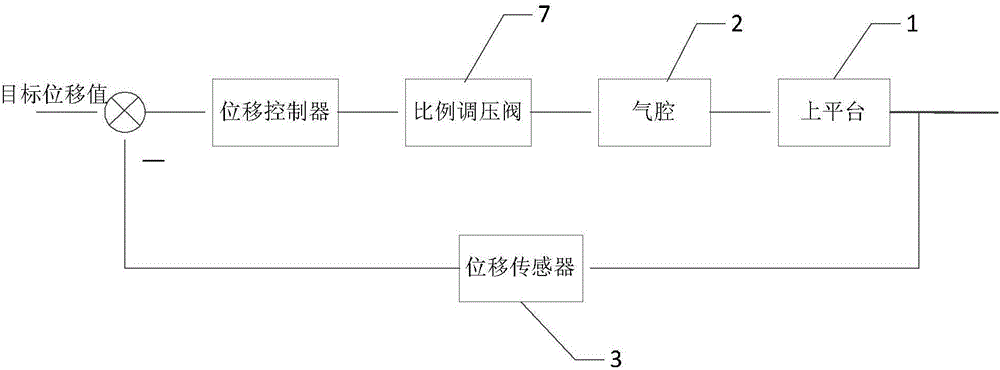

[0022] Specific implementation mode one: combine figure 1 , 2 and image 3 Describe this embodiment, the vertical air pressure control system of an air bearing platform described in this embodiment, the control system includes a displacement sensor 3, a pressure sensor 4 and a controller 8;

[0023] The air flotation platform of this implementation includes an upper platform body 1, an air chamber 2, a gas source 5, an air intake valve 6 and a proportional pressure regulating valve 7; the gas source 5 adopts high-pressure nitrogen to improve the quality of the gas. It regulates the pressure of the gas entering the air chamber 2 through the inlet valve 6 . The proportional pressure regulating valve 7 is used as the exhaust valve of the air cavity 2 . The air cavity drives the upper platform body 1 to move vertically.

[0024] The displacement sensor 3 is installed on the inner side of the air cavity 2 of the air bearing platform, and is used to measure the displacement of t...

specific Embodiment approach 2

[0031] Specific embodiment two: a control method for the vertical air pressure control system of the air bearing platform described in this embodiment,

[0032] The method is realized through the control of the controller 8, and the working process of the controller 8 includes:

[0033] Step 1: Control the intake valve 6, so that the gas in the gas source 5 enters the air cavity 2, so that the upper platform 1 moves;

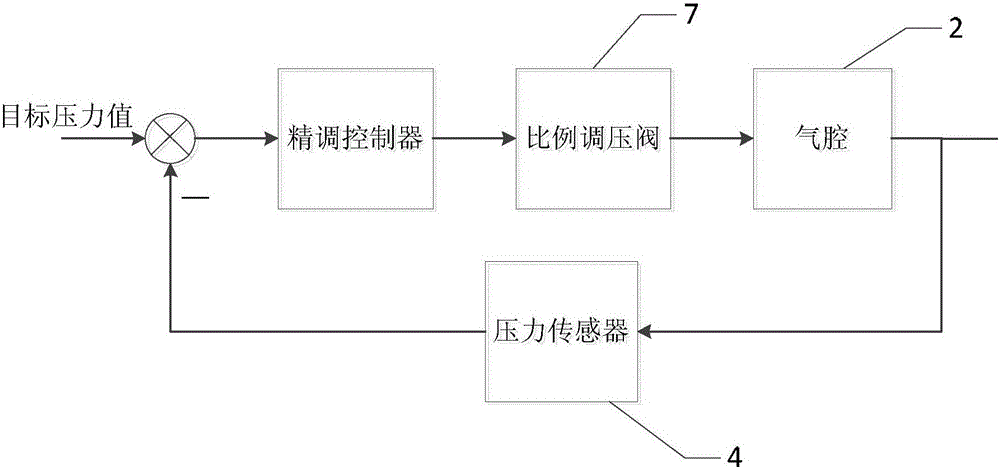

[0034] Step 2: Randomly set an effective value within a stroke range, control the proportional pressure regulating valve 7 according to the effective value, and adjust the air pressure of the air chamber 2;

[0035] Step 3: Collect the displacement measurement value of the displacement sensor 3 in real time, subtract the displacement measurement value from the target displacement value, and judge whether the obtained difference is less than the set control accuracy. At this time, the speed is basically zero. If so, then real-time Collect the pressure measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com